Push rod resetting mechanism of needleless injector

A technology of needle-free injector and reset mechanism, which is applied in the direction of syringes, hypodermic injection devices, injectors with jetting action, etc. It can solve the problems of complicated operation and low reset accuracy, and achieve the effect of simple operation and high reset accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

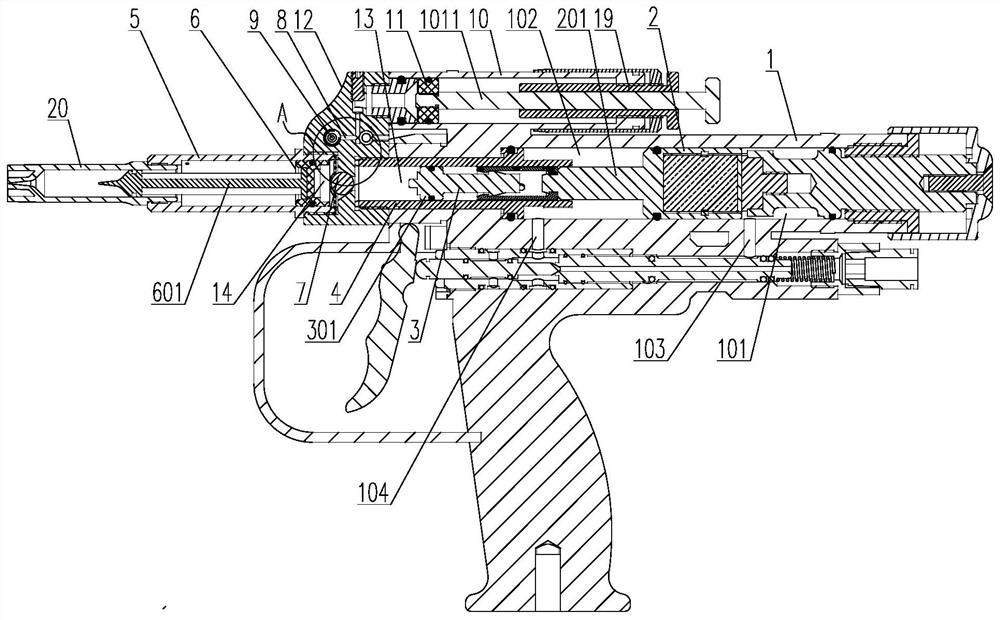

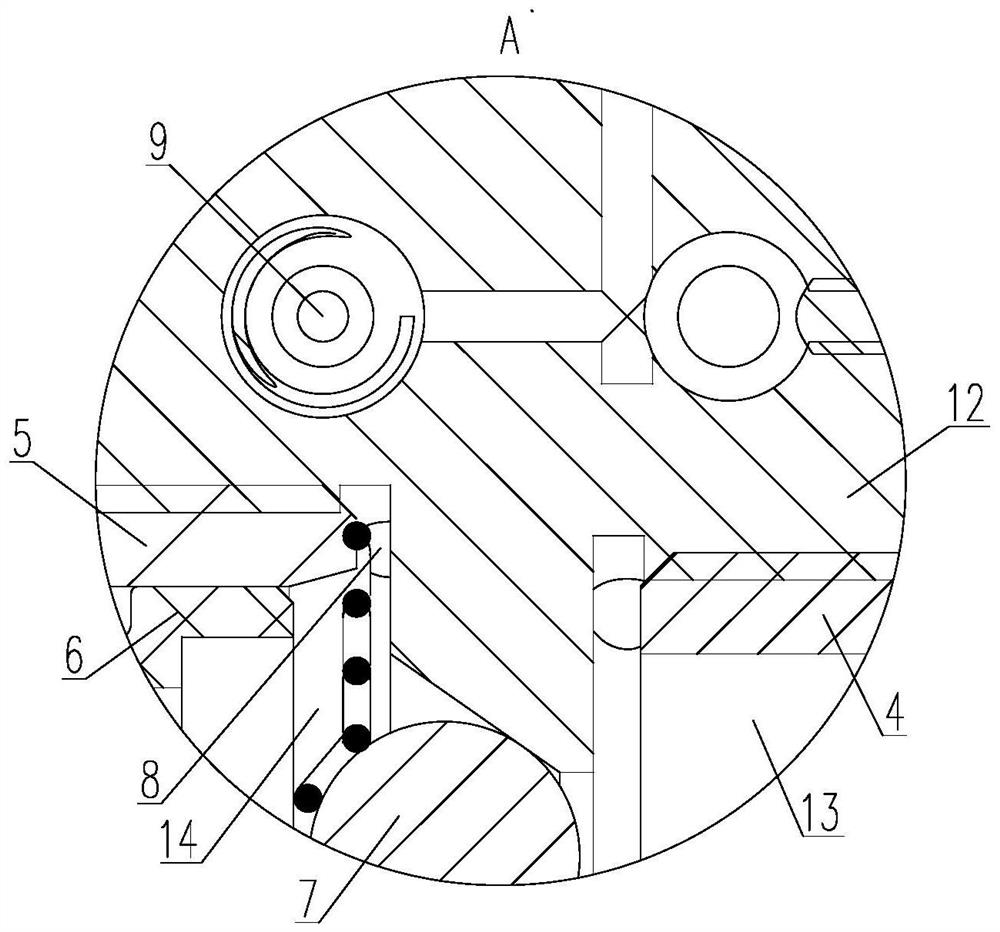

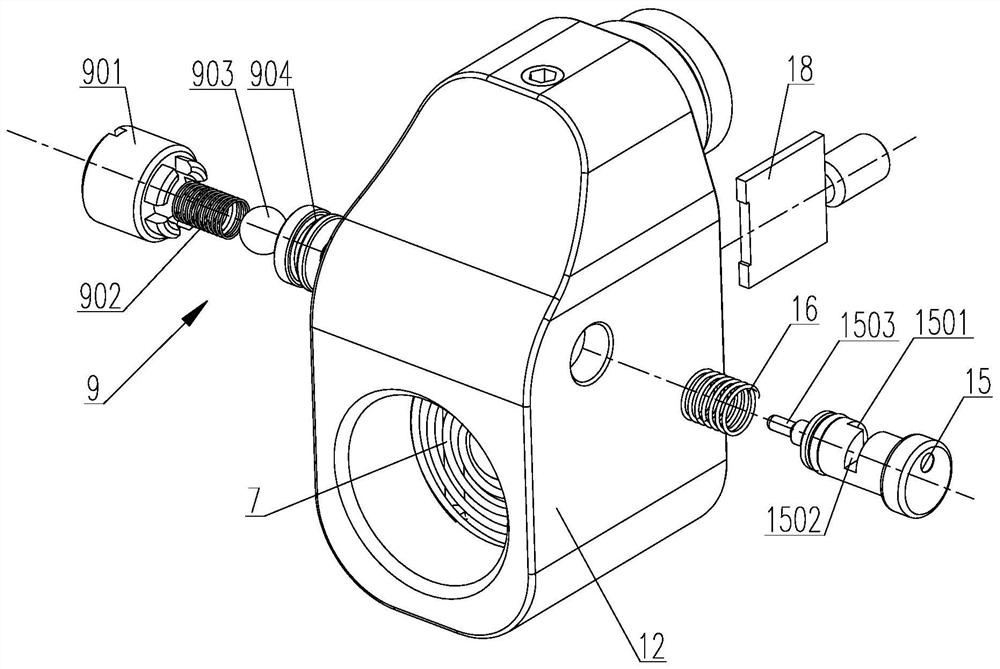

[0029] Such as Figure 1-8 As shown, a push rod reset mechanism of a needle-free injector, the needle-free injector includes a gun body 1, an outer hydraulic tube 5, an inner hydraulic tube 4 and a power mechanism, and the inner hydraulic tube 4 is fixed in the gun body 1, The outer hydraulic pipe 5 is fixed on the front end of the gun body 1, the tail end of the outer hydraulic pipe 5 communicates with the head end of the inner hydraulic pipe 4, and the outer hydraulic pipe 5 is provided with a push rod 601 for injection, and the push rod 601 A stepping piston 6 is fixed on the tail end of the upper body, and the stepping piston 6 is slidably installed in the outer hydraulic pipe 5, and a hydraulic piston 301 is slidably installed in the inner hydraulic pipe 4, and the power mechanism is used to drive the hydraulic piston 301 along the inner hydraulic pressure. The axial direction of the tube 4 reciprocates. The push rod reset mechanism includes an oil storage cylinder 10 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com