Multi-row gun nail clip capable of preventing nails from being stuck

A technology of magazine clips and gun nails, applied in the field of gun nails, can solve the problems of increasing the labor intensity of workers, the nail bars cannot be firmly limited, and the bottom row nail bars cannot be pushed, etc., so as to improve the working efficiency of nailing, the structure is ingenious, and the The effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

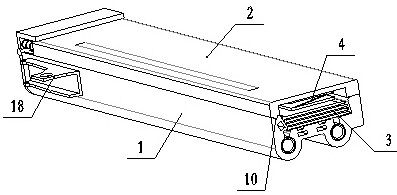

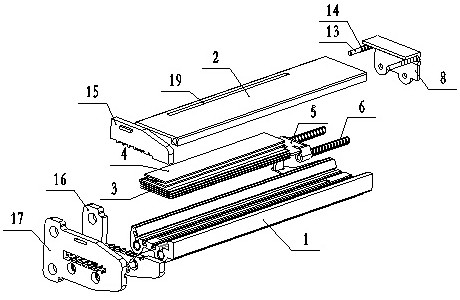

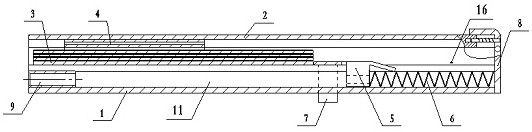

[0032] see Figure 1 to Figure 6 A multi-row nail clip for anti-stabbing, including a fixed clip 1, characterized in that: the fixed clip 1 is provided with a chamber for placing a nail strip 3, and the left side of the chamber 1-5 The slope parallel to the right side 1-6 forms an angle with the bottom surface 1-7 of the chamber. The bottom of the fixed magazine 1 is provided with two circular guide grooves 1-1, and the guide groove 1-1 is provided with There is an opening 1-2, and the opening 1-2 communicates with the chamber for fixing the clip 1; multiple rows of nail strips 3 are installed in the chamber, and springs 6 and nail pushing pieces are installed in the guide groove 1-1 5. The spring 6 can push the nail pusher 5 to push the nail strip 3 out of the nail outlet; the middle part of the fixed clip 1 is provided with a through groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com