Method and equipment for realizing buzzing through vibration of stepping motor of printer

A technology of stepping motors and printers, applied in printing devices, motor generator control, printing, etc., can solve the problems of high implementation cost, occupying CPU port resources, etc., and achieve the effect of increasing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

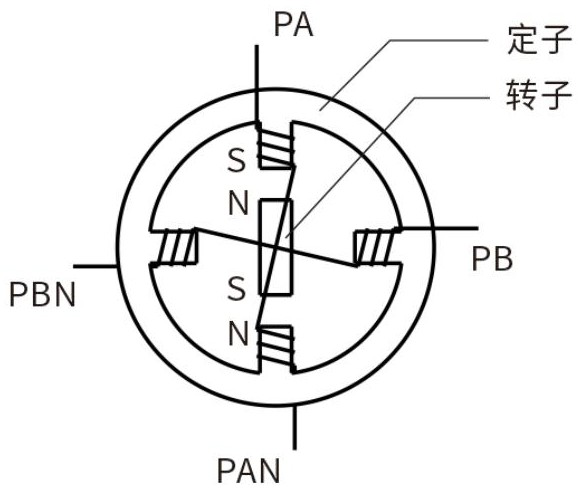

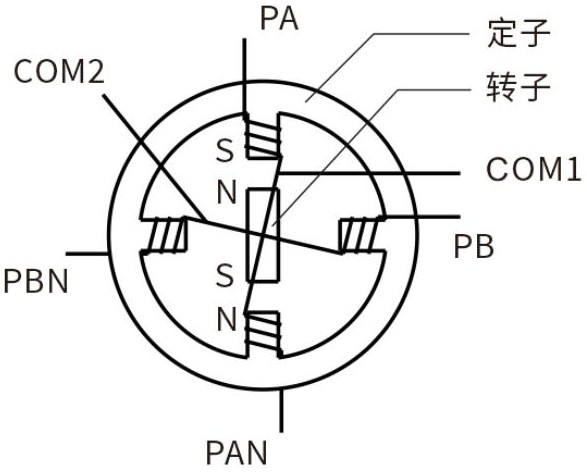

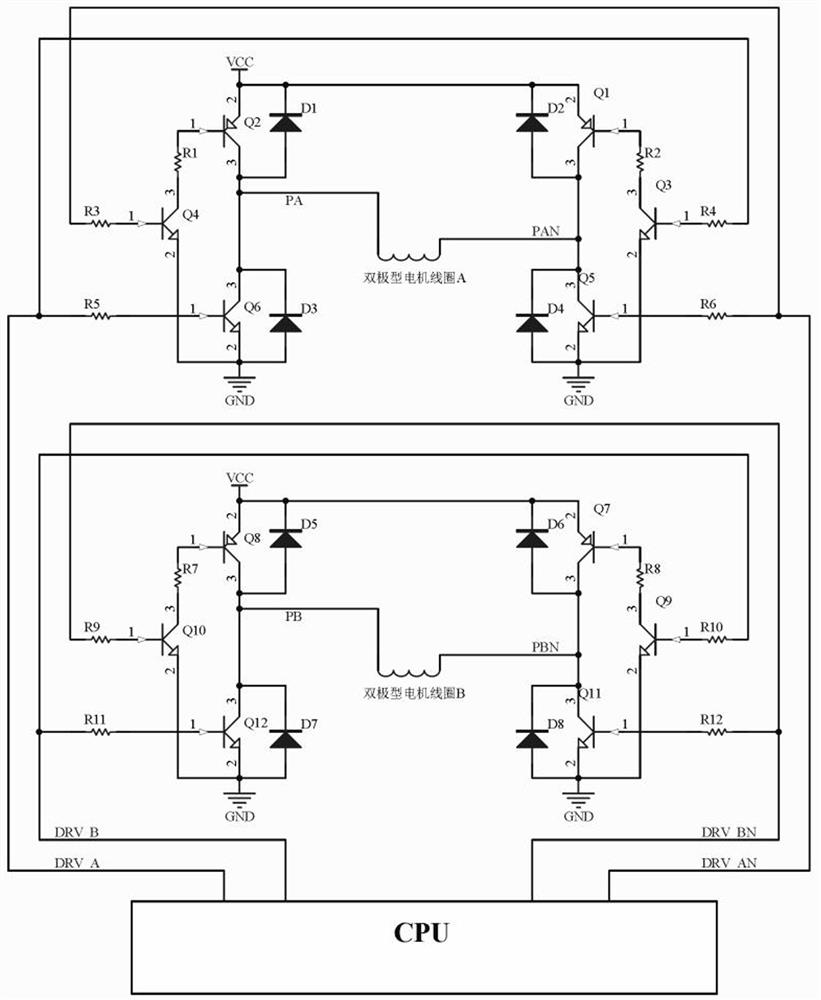

[0042] In this embodiment, a bipolar motor is taken as an example for illustration, such as figure 1 , image 3 as well as Figure 5 shown.

[0043] When the stepper motor of the printer stops running, when the CPU of the printer controller receives a buzzer prompt or warning action, the CPU starts the buzzer driver control program to execute. Drive signals DRV_A, DRV_AN, DRV_B, DRV_BN are generated by the control program on the physical ports of the CPU.

[0044] In the initial state, the driving signals DRV_A and DRV_AN are at low level, at this time, the switching tubes Q1, Q2, Q5, and Q6 of the driving circuit of the stepping motor coil A are all closed, and the coil A of the stepping motor does not pass through the excitation current; at the same time When the drive signals DRV_B and DRV_BN are at low level, the switch tubes Q7, Q8, Q11 and Q12 of the drive circuit of the coil B of the stepping motor are all turned off, and the coil B of the stepping motor has no excit...

Embodiment 2

[0050] In this embodiment, the unipolar motor is taken as an example for illustration, such as figure 2 , Figure 4 as well as Figure 5 shown.

[0051] The timing sequence of the driving signal is the same as that of the first embodiment, and the realization principle is the same as that of the first embodiment, the only difference is that the corresponding difference between the driving signal and the switch of the switching tube of the driving circuit is different. Specifically include the following steps:

[0052] When the stepper motor of the printer stops running, when the CPU of the printer controller receives a buzzer prompt or warning action, the CPU starts the buzzer driver control program to execute. Drive signals DRV_A, DRV_AN, DRV_B, DRV_BN are generated by the control program on the physical ports of the CPU.

[0053] In the initial state, the driving signals DRV_A and DRV_AN are at low level. At this time, the switching tubes Q13 and Q15 of the driving circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com