Treatment methods for ro-ro ship moorings adjacent to dangerous areas

A technology for mooring equipment and dangerous areas, which is applied to marine signal devices, ship components, ship construction, etc. It can solve the problems of unacceptable shipowners, increased shipyard construction costs, and inconvenient crew access to mooring areas, etc., to reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

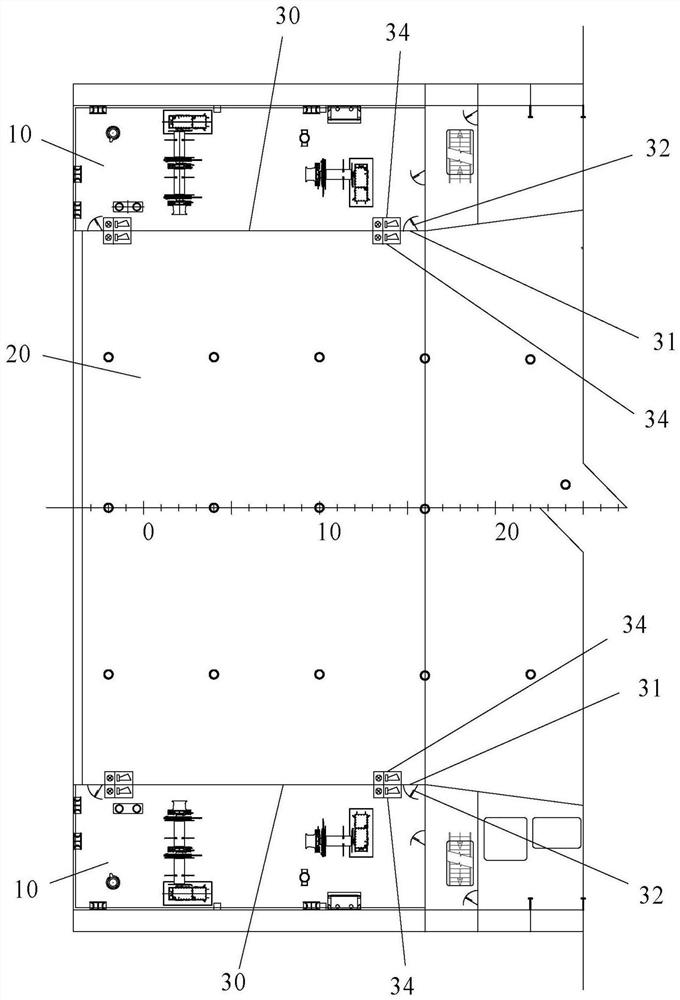

[0023] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

[0024] like figure 1 As shown, a processing method for a ro-ro ship mooring equipment adjacent to a hazardous area, which includes the following steps:

[0025] In step 1, the ro-ro ship is provided with a ro-ro area 20 and a mooring area 10. The mooring area 10 and the ro-ro area 20 are separated by a separation bulkhead 30, and the separation bulkhead 30 is provided with one or more entrances and exits 31. In this embodiment, two entrances and exits are provided on the dividing bulkhead.

[0026] Only one airtight self-closing door 32 is provided for each entrance and exit 31 . When the airtight self-closing door is opened, the main body of the airtight self-closing door is located in the mooring area. The mooring area 10 is not provided with explosion-proof mooring equipment.

[0027] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com