Automatic garbage classification treatment system for high-rise buildings

A technology for high-rise buildings and garbage classification, applied in buildings, trash cans, building components, etc., it can solve the problems of household trouble, waste of human resources, and pollution of residential residents, and save time, save labor, and protect the air and the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

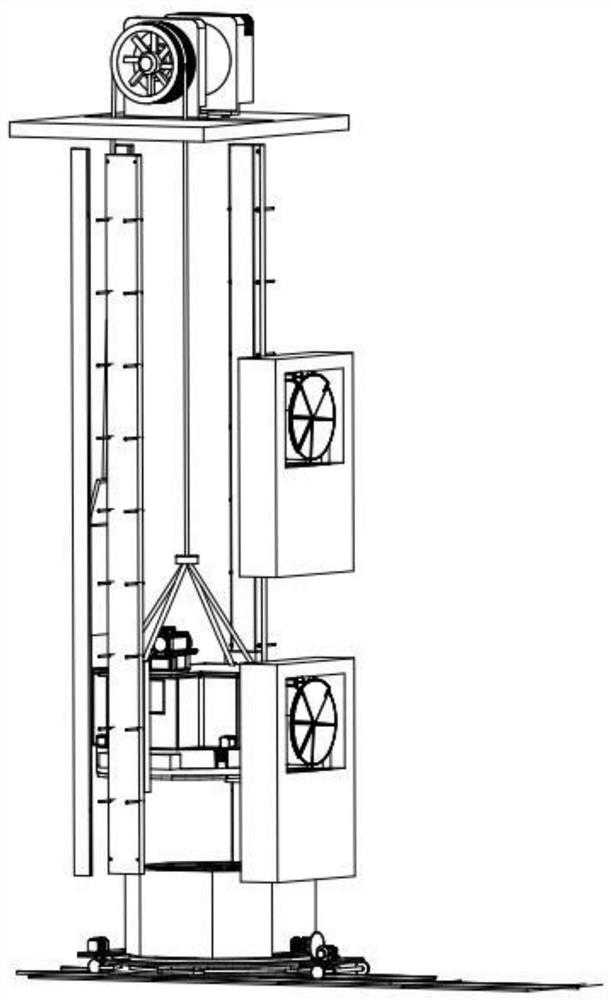

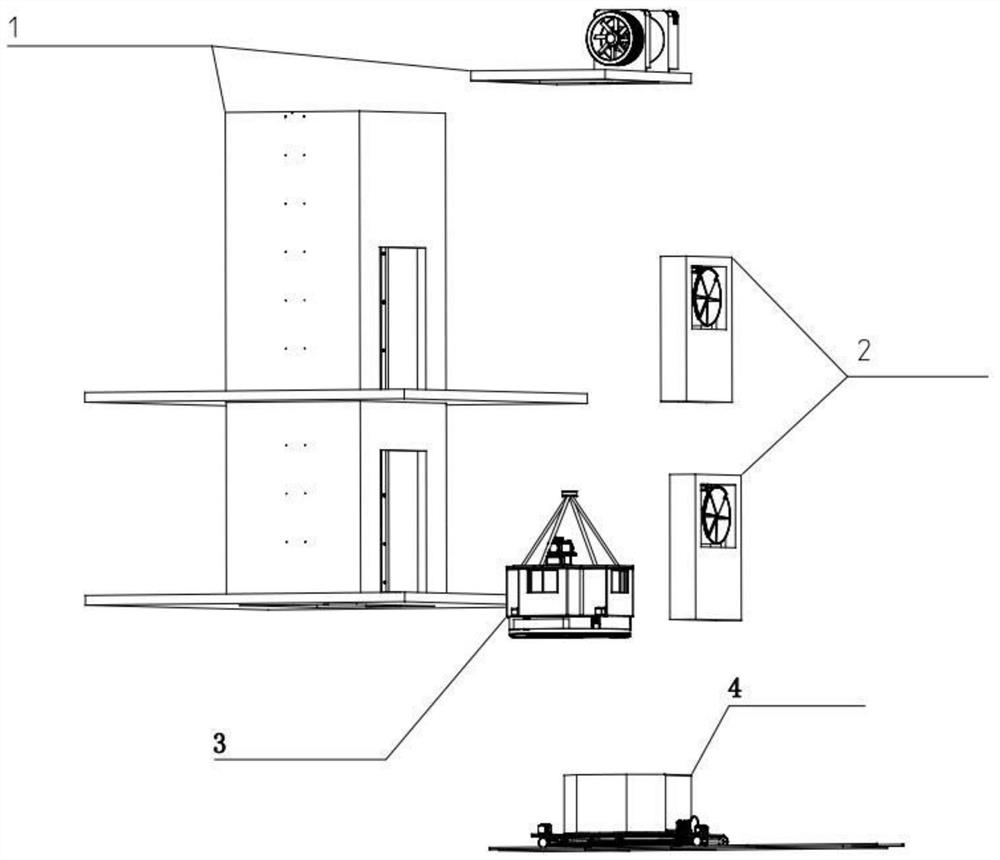

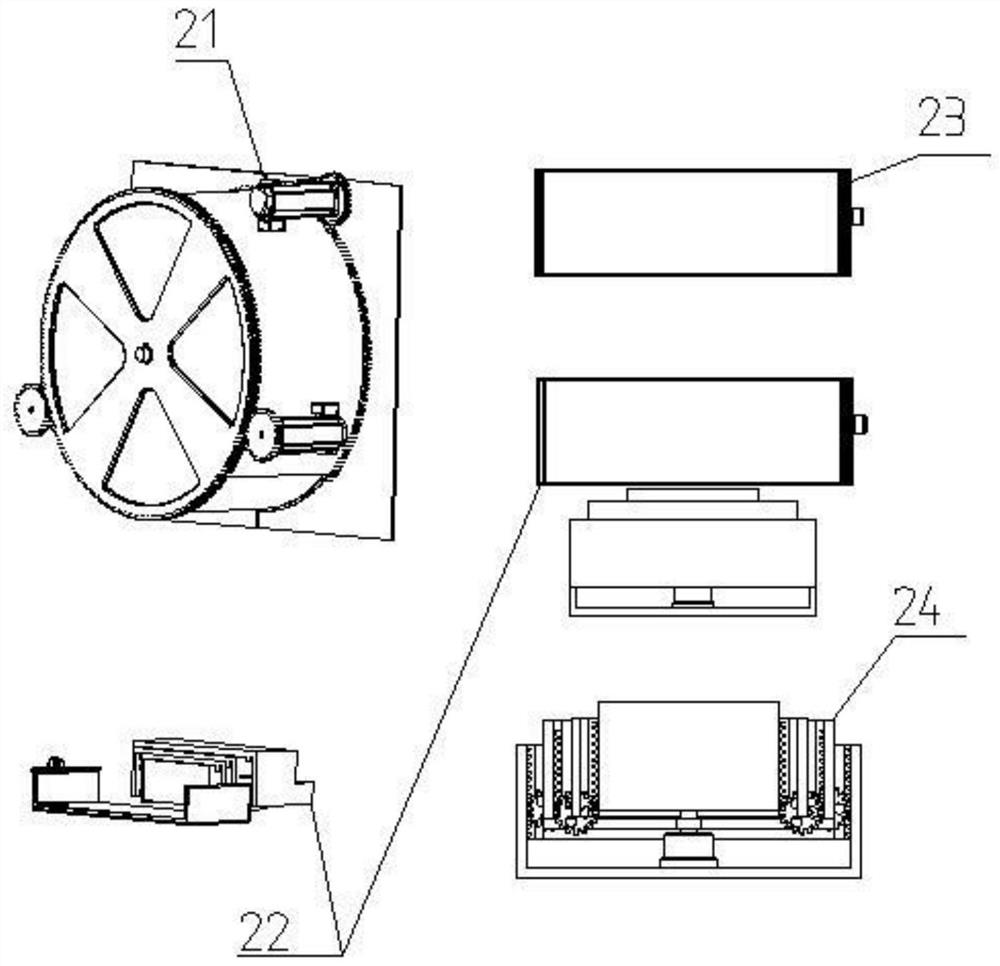

[0031] see Figure 1-11 , the high-rise building automatic garbage classification processing system, comprising a car transport well 1, a temporary garbage storage device 2, a garbage collection trolley 3 and a garbage transport trolley 4, the temporary garbage storage devices 2 are multiple and located at equal intervals in the trolley transport well 1 Set, the garbage collection trolley 3 is located in the trolley transport well 1, the garbage transport trolley 4 is located at the bottom of the trolley transport well 1, and on the top of the trolley transport well 1, there is a traction machine, dovetail groove guide rail, counterweight and traction rope. The transportation mechanism is connected with the garbage collection trolley 3 .

[0032] When working, the traction motor drives the traction wheel to rotate after the speed is changed by the reducer, and the traction force generated by the friction between the traction wheel and the traction wheel realizes the relative l...

Embodiment 2

[0038] On the basis of Embodiment 1, the side of the first flap door 3513 is provided with a door handle 3514, which is convenient for personnel to manually open for maintenance when the adjustment servo motor 3512 fails; the side of the second flap door 432 is provided with The handle 436 is manually adjusted, which is convenient for personnel to manually open it for maintenance when the external servo motor fails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com