Launder structure convenient for replacing wire-drawing bushing and method for replacing wire-drawing bushing

A wire drawing bushing and launder technology, which is applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of replacing wire drawing bushings, etc., and achieve the effect of prolonging the service life and improving the efficiency of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

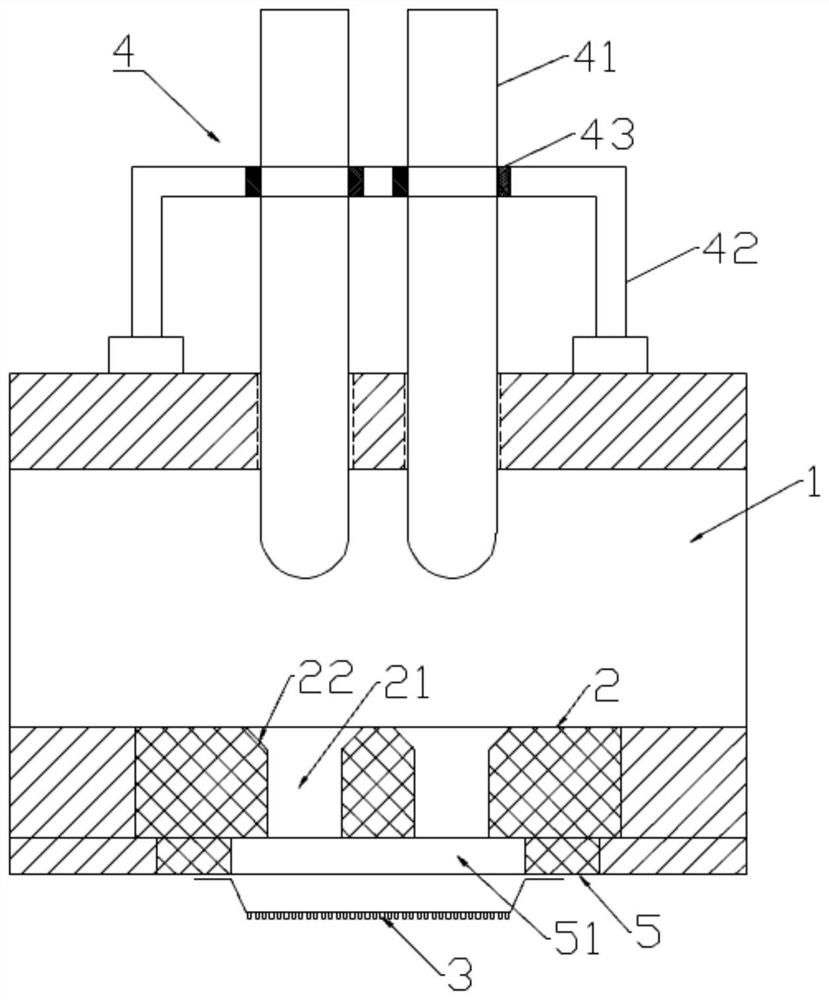

[0020] Such as figure 1 As shown, a launder structure includes a working passage 1, a launder brick 2, a bushing brick 5, a drawing bushing 3 and a punch mechanism 4; the launder brick 2 is arranged at the bottom of the working passage 1, The bushing brick 5 is arranged at the bottom of the runner brick 2, the brushed bushing 3 is installed at the bottom of the bushing brick 5, the runner brick 2 is provided with a flow hole 21, the drain The plate brick 5 is provided with a leakage hole 51, and the liquid flow hole 21 communicates with the leakage hole 51; the punch mechanism 4 includes a flow-blocking punch 41 and a lifting mechanism (attached) for lifting the flow-blocking punch 41 Not shown in the figure), the flow blocking punch 41 is arranged on the top of the working channel 1 , and the flow blocking punch 41 is used to block the flow hole 21 . The lifting mechanism adopts the existing technology, and can use a hydraulic cylinder to provide lifting power or a motor dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com