Preparation method of in-situ reaction sic composite material in a fiber bundle

An in-situ reaction and composite material technology is applied in the field of preparation of fiber toughened ceramic matrix composite materials. rate, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Mix the high carbon residue polycarbosilane, SiC powder and silicon powder evenly, and mix them by ball milling for 2 hours to obtain a uniformly mixed liquid precursor slurry, high carbon residue polycarbosilane, SiC powder, and silicon powder. The weight ratio is 2:2:1;

[0033] Step 2, in a muffle furnace, in an air atmosphere, treat at 500°C for 4 hours to remove the sizing agent;

[0034] Step 3, depositing a pyrolytic carbon (PyC) interface layer on the surface of the fiber bundle, and then depositing a SiC interface layer with a thickness of 300 nm;

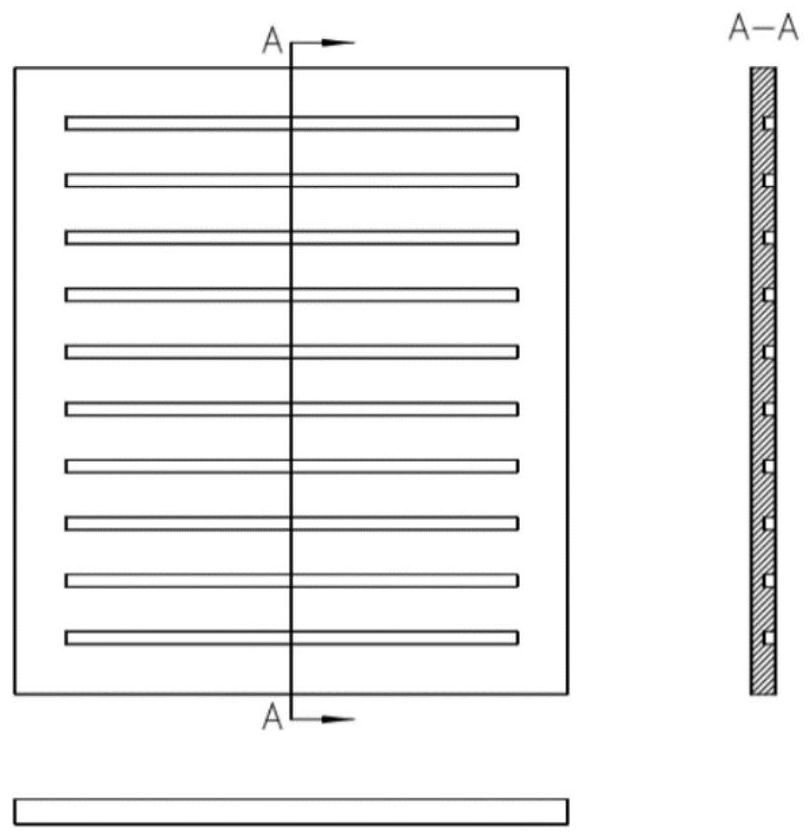

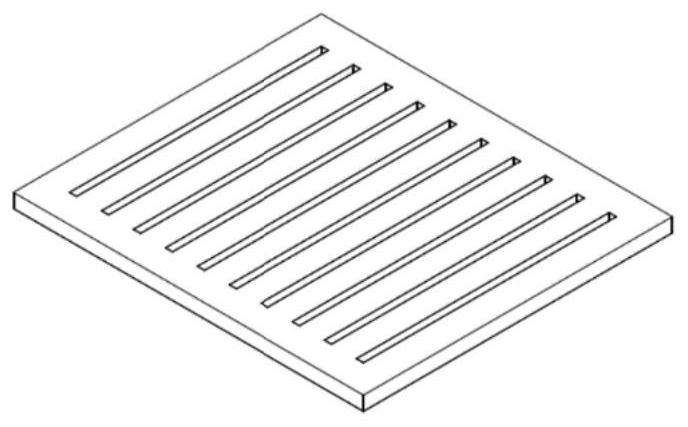

[0035] Step 4, the deposited fiber bundle is cut into a long section of 15cm, and evenly placed on the graphite tooling (such as figure 1 (shown), pour the prepared slurry into the slurry, the fibers are completely immersed in the slurry, put into a vacuum oven, and immersed in a vacuum for 2 hours to obtain a fiber precursor slurry;

[0036] Step 5. Take out the impregnated fiber bundles from the slurry, ...

Embodiment 2

[0041] Step 1. Evenly mix the high carbon residue polycarbosilane, SiC powder and silicon powder, and mix by ball milling for 3 hours to obtain a uniformly mixed liquid precursor slurry, high carbon residue polycarbosilane, SiC powder, and silicon powder. The weight ratio is 1:1:2;

[0042] Step 2, in a muffle furnace, in an air atmosphere, treat at 450 ° C for 2 hours to remove the sizing agent;

[0043] Step 3, depositing a pyrolytic carbon (PyC) interface layer on the surface of the fiber bundle, and then depositing a SiC interface layer, with thicknesses of 200 nm and 600 nm, respectively;

[0044] Step 4, the deposited fiber bundle is cut into a long section of 15cm, and evenly placed on the graphite tooling (such as figure 1 (shown), pour the prepared slurry into the slurry, the fibers are completely immersed in the slurry, put into a vacuum oven, and immersed in a vacuum for 3 hours to obtain a fiber precursor slurry;

[0045] Step 5. Take out the impregnated fiber bu...

Embodiment 3

[0050] Step 1. Mix the high carbon residue polycarbosilane, SiC powder and silicon powder evenly, and mix them by ball milling for 4 hours to obtain a uniformly mixed liquid precursor slurry, high carbon residue polycarbosilane, SiC powder, and silicon powder. The weight ratio is 5:1:4;

[0051] Step 2, in a muffle furnace, in an air atmosphere, treat at 500°C for 4 hours to remove the sizing agent;

[0052] Step 3, depositing a pyrolytic carbon (PyC) interface layer on the surface of the fiber bundle, and then depositing a SiC interface layer, with thicknesses of 300 nm and 400 nm, respectively;

[0053]Step 4, the deposited fiber bundle is cut into a long section of 15cm, and evenly placed on the graphite tooling (such as figure 1 (shown), pour the prepared slurry into the slurry, and the fibers are completely immersed in the slurry, put into a vacuum oven, and immersed in a vacuum for 5 hours to obtain a fiber precursor slurry;

[0054] Step 5. Take out the impregnated fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap