Production method of combed polyester cotton yarn

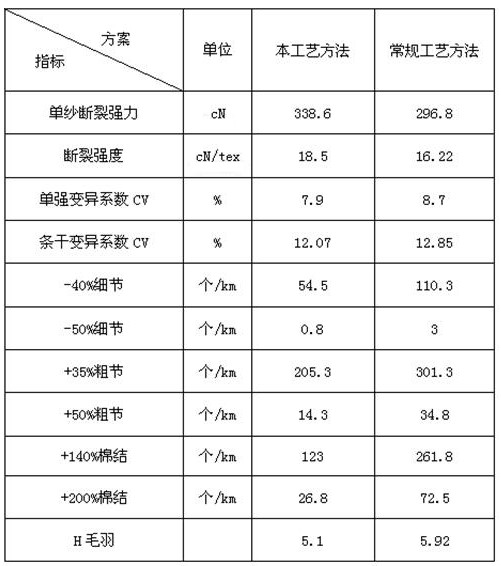

A production method and technology for combed cotton, applied in the directions of yarn, textiles and papermaking, can solve the problems of increasing coarse and fine defects in the spinning process, reducing the strength of the roving, increasing the hairiness of the roving, etc., so as to improve the evenness of evenness and the uniformity of coarse and fine details. The effect of improving the yarn strength and improving the yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] 1. Combed polyester-cotton yarn with a linear density of 18.5tex and a JC / T blending ratio of 60 / 40:

[0013] 1. Raw material equipment:

[0014] Cotton fiber allocation principles: choose hand-picked cotton, with maturity above 0.85, short-lint rate within 13%, foreign fiber content within 0.3g / t, and neps within 180 / g.

[0015] The principle of polyester fiber allocation: choose large chemical fiber polyester, control the defect content within 1mg / 100g, the coefficient of variation of fiber breaking strength within 20%, and the consistency of fiber dyeing performance is good.

[0016] 2. Open and clean cotton:

[0017] The selected cotton fibers are grabbed sequentially by the FA002 disc bale opener according to the mixing ratio, and the preliminary opening and mixing of the cotton fibers are realized during the catching process, and the plucked cotton fibers are captured by the A035 mixing opener The cotton fiber is opened, and the main mixing action and the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com