Novel intelligent electric pressure-adjusting spring cradle

A pressure-regulating spring, electric technology, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of low work efficiency, inability to achieve stepless pressure regulation, and high labor intensity of operators, and achieve yarn production. The effect of improving wire quality and breakage rate, reducing labor intensity and convenient pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

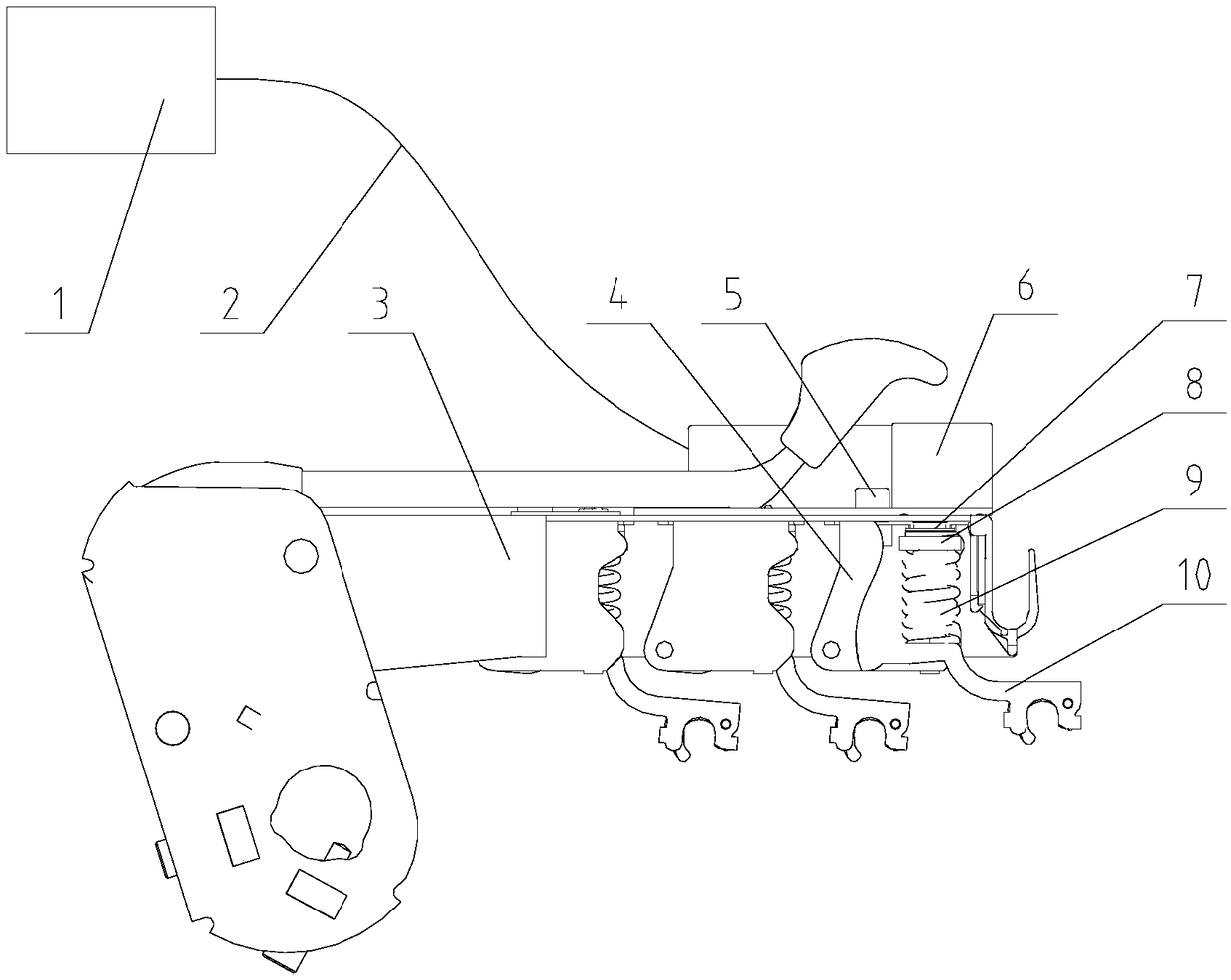

[0017] The present invention will be further described below in conjunction with accompanying drawing and detailed implementation rules.

[0018] Referring to the attached picture:

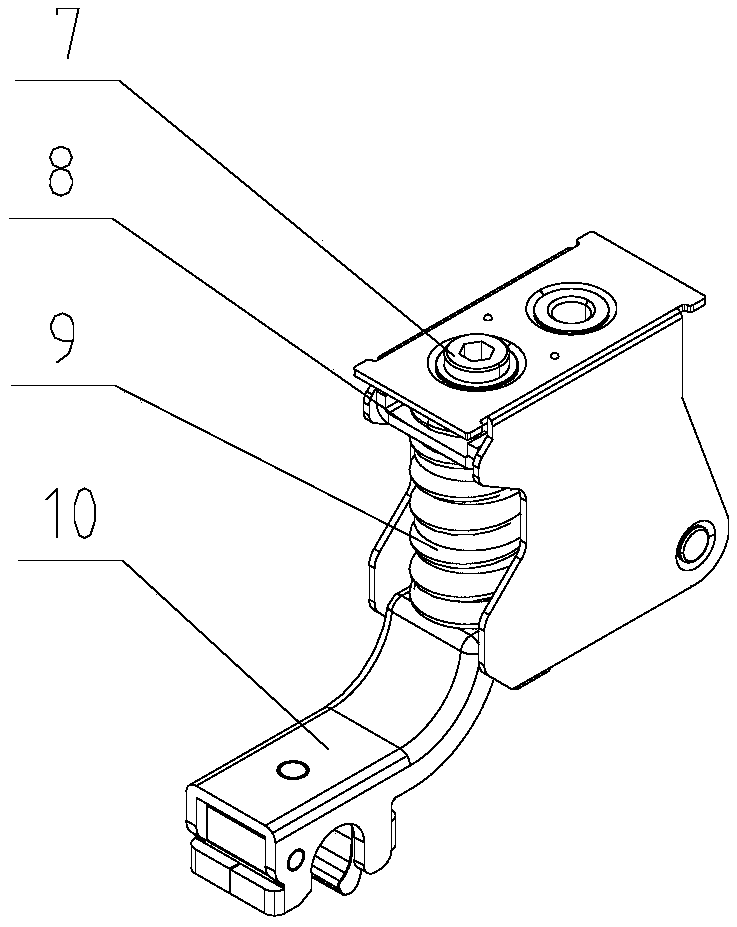

[0019] Put the pressure regulating screw 7, the pressure regulating nut 8, and the spring 9 into the bracket 4, install the pressure rod 10 on the bracket 4 through the connecting pin, and form a single pressure assembly together. When working, the motor controller 1 will control the instruction It is transmitted to the motor 6 of each cradle through the bus 2, and the motor 6 is used to drive the pressure regulating screw 7 to rotate, so that the pressure regulating nut 8 is displaced and the compression amount of the spring 9 is changed to realize the electric stepless adjustment of the working pressure of the cradle and the cradle Automatic switching between half relief and working pressure. The motors can be controlled simultaneously or staggered in groups.

[0020] The above-mentioned movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com