Construction method of high-altitude double-layer super-long cantilever reinforced concrete structure

A reinforced concrete and construction method technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., to achieve the effects of optimizing the stress system, preventing force cracking, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

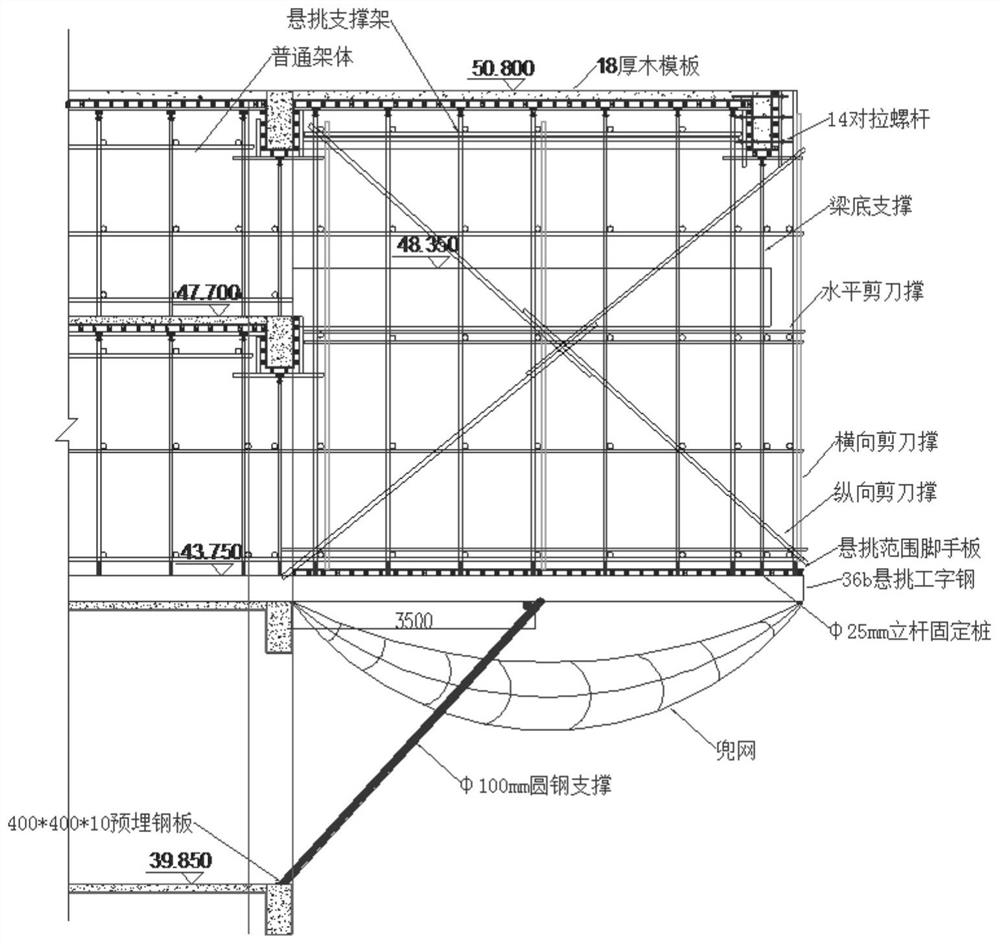

[0049] The construction method of the high-altitude double-layer super-long cantilever reinforced concrete structure of the present invention is specifically as follows:

[0050] S1. The cantilever beam adopts cantilever steel as the foundation of the supporting scaffold. The cantilever steel is fixed by the pre-embedded steel pull ring in the floor slab. The upper part of the cantilever steel is equipped with a steel pipe fastener type full house scaffold;

[0051] S2. In combination with the different cantilever lengths, calculate the bending moment of the lower section steel of the cantilever beam and calculate the support of the cantilever beam to meet the length Install oblique steel supports (steel supports can be steel pipes, section steels, etc.) at the bottom of the cantilevered steel to form a triangular stable force system

[0052] Among them, the cantilevered section steel adopts 36b section steel, and the lower section of the section steel is equipped with A100mm steel p...

Embodiment 2

[0079] As attached Figure 5 As shown, the process flow of the construction method of the high-altitude double-layer super-long cantilever reinforced concrete structure of the present invention is as follows:

[0080] (1) Measuring and setting out;

[0081] (2) Pre-embedded anchor plate;

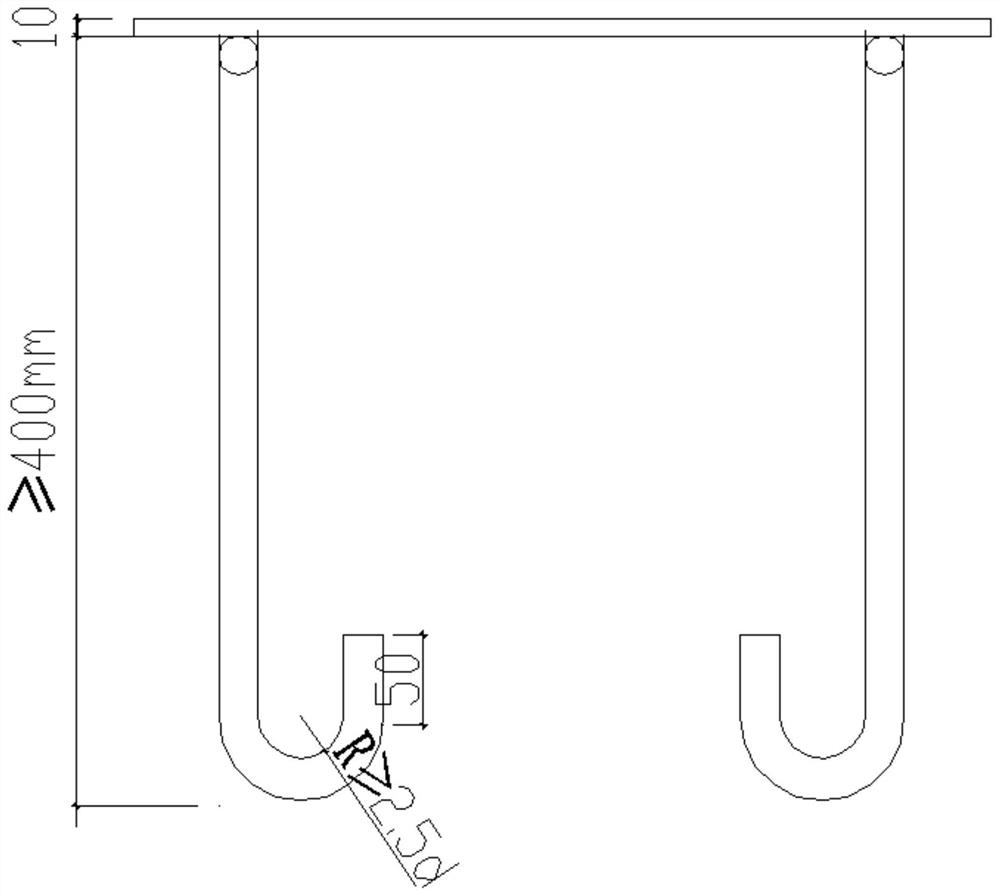

[0082] (3) U-shaped pull ring installation and side beam buried plate;

[0083] (4) Install I-beam,;

[0084] (5). Installation of the inner frame and diagonal support; the installation of the inner frame is as follows:

[0085] (5-1-1), internal erection;

[0086] (5-1-2), steel bar processing;

[0087] (5-1-3), Lay scaffolding boards and frame erection;

[0088] The installation of inclined support is as follows:

[0089] (5-2-1), diagonal support installation;

[0090] (5-2-2), cantilever steel horizontal rod connection;

[0091] (5-2-3), diagonal support horizontal and diagonal connecting rod;

[0092] (5-2-4) Ribbing at the overlapping part of diagonal support and section steel;

[0093] (6) Supporting be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com