Eddy current sensor probe sensitivity and linearity optimization method and system

An eddy current sensor and optimization method technology, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems such as large amount of calculation and difficult probe design, and achieve the effect of overcoming large amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

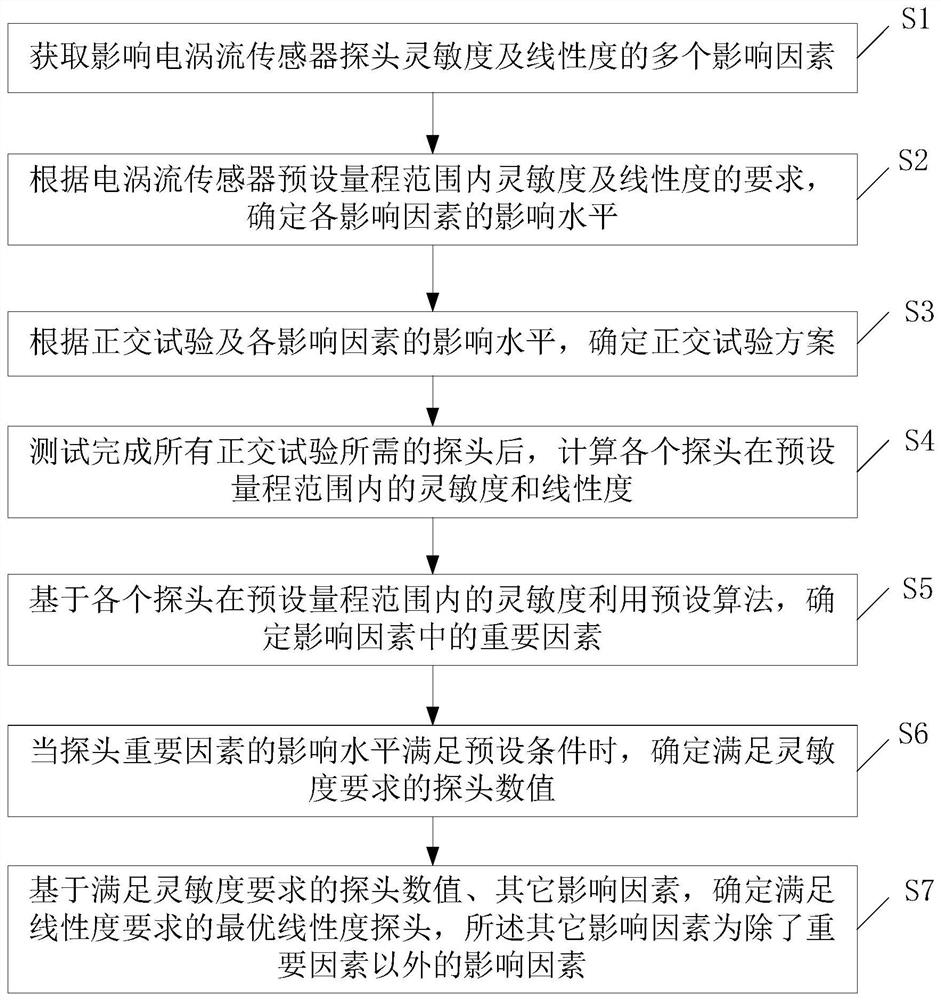

[0043] A method for optimizing the sensitivity and linearity of an eddy current sensor probe provided in an embodiment of the present invention, such as figure 1 shown, including the following steps:

[0044] Step S1: Obtain multiple influencing factors affecting the sensitivity and linearity of the eddy current sensor probe.

[0045] In the embodiment of the present invention, the influencing factors include: at least one of the inner and outer radii of the sensor probe coil, the diameter of the enameled wire, and the thickness of the coil. This is just an example and not limited thereto. In practical applications, select the corresponding influence according to actual needs. factors, the embodiment of the present invention optimizes the sensitivity and linearity of the eddy current sensor probe by optimizing the coil.

[0046] Step S2: According to the requirements of sensitivity and linearity within the preset measuring range of the eddy current sensor, determine the influen...

Embodiment 2

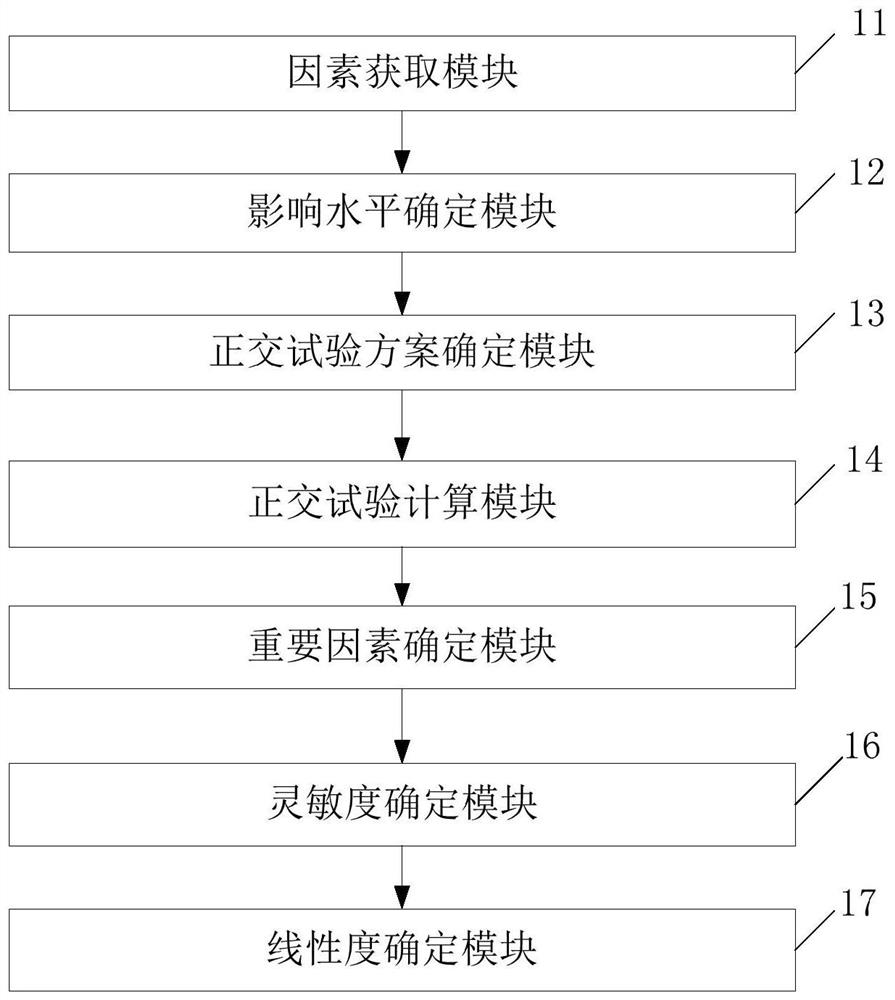

[0061] An embodiment of the present invention provides an eddy current sensor probe sensitivity and linearity optimization system, such as image 3 shown, including:

[0062] The factor obtaining module 11 is used to obtain multiple influencing factors affecting the sensitivity and linearity of the eddy current sensor probe; this module executes the method described in step S1 in Embodiment 1, which will not be repeated here.

[0063] Influence level determining module 12 is used to determine the influence level of each influencing factor according to the requirements of sensitivity and linearity in the preset range of the eddy current sensor; this module executes the method described in step S2 in Embodiment 1, and is not described Let me repeat.

[0064] Orthogonal test scheme determination module 13 determines the orthogonal test scheme according to the orthogonal test and the influence level of each influencing factor; this module executes the method described in step S3 ...

Embodiment 3

[0071] An embodiment of the present invention provides a terminal, such as Figure 4 As shown, it includes: at least one processor 401 , such as a CPU (Central Processing Unit, central processing unit), at least one communication interface 403 , memory 404 , and at least one communication bus 402 . Wherein, the communication bus 402 is used to realize connection and communication between these components. Wherein, the communication interface 403 may include a display screen (Display) and a keyboard (Keyboard), and the optional communication interface 403 may also include a standard wired interface and a wireless interface. The memory 404 may be a high-speed RAM memory (Random Access Memory, volatile random access memory), or a non-volatile memory (non-volatile memory), such as at least one disk memory. Optionally, the memory 404 may also be at least one storage device located away from the aforementioned processor 401 . The processor 401 can execute the method for optimizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap