Circuit board electrical performance detection method for assembly line

A detection method and board electrical technology, applied in electronic circuit testing, non-contact circuit testing, measuring resistance/reactance/impedance, etc., can solve problems such as product quality impact, inability to detect circuit board material properties, slow test speed, etc. , to achieve the effect of low cost, convenient installation structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

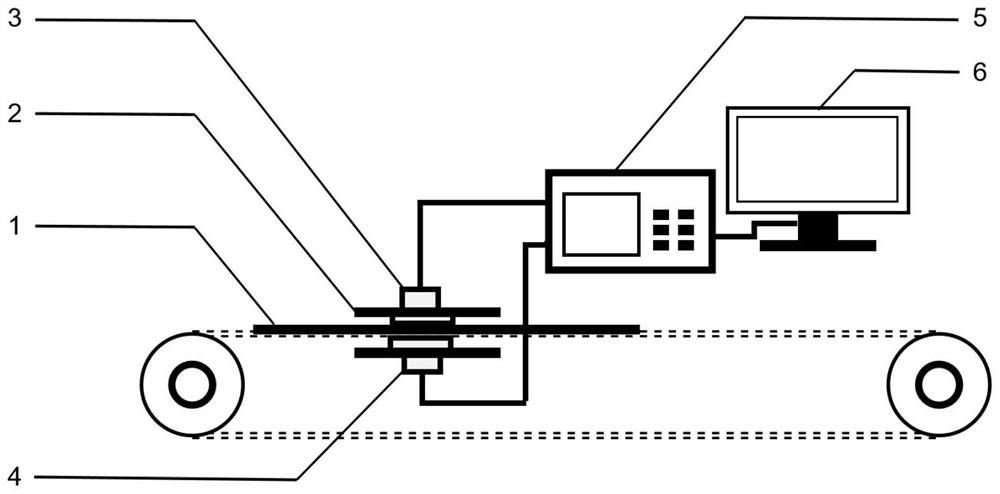

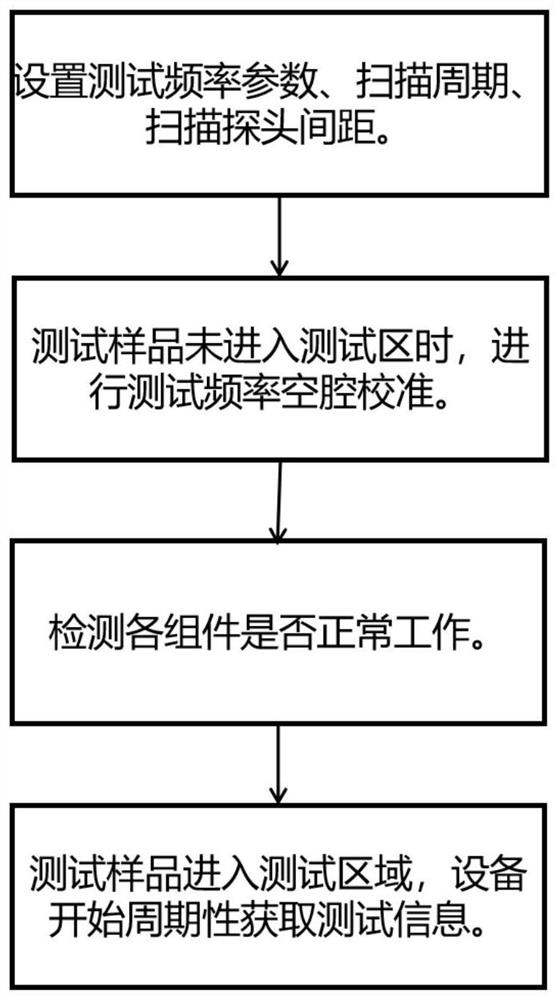

[0020] The invention provides a fast and convenient method for detecting the quality of the circuit board base material for the industrial circuit board production line. The method can provide auxiliary tests for circuit board quality testers in the operation of the circuit board production line, so as to quickly obtain the dielectric properties and losses of the tested samples.

[0021] In the following, the detailed technical methods in the implementation of the present invention will be described in conjunction with the principle drawings of this patent, and the actual testing method of the present invention will be described in detail.

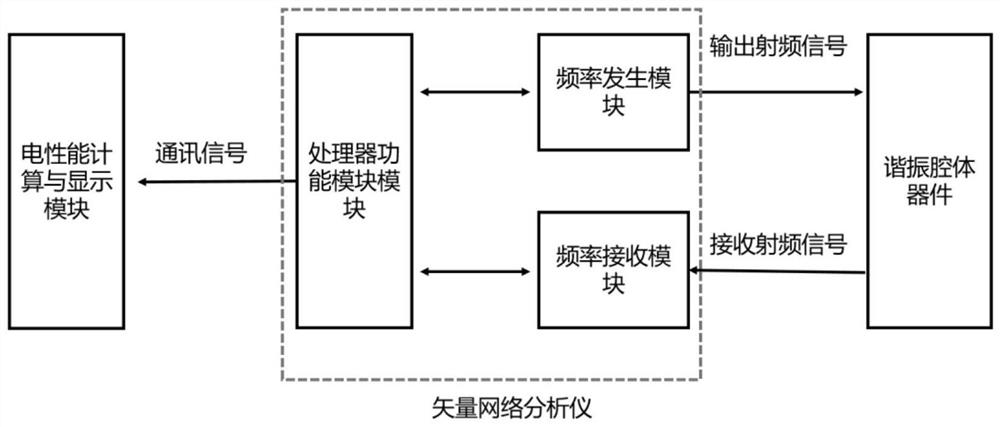

[0022] The present invention relates to the testing principle of the equipment:

[0023] In the circuit board base material, its main component is the dielectric material. Under the influence of the resonance of the radio frequency signal, this kind of material has a certain influence on the echo, which makes the resonance peak of the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com