A pole piece winding method and rolled pole piece

A pole piece and rolling technology is applied to the field of pole piece winding method and rolled pole piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

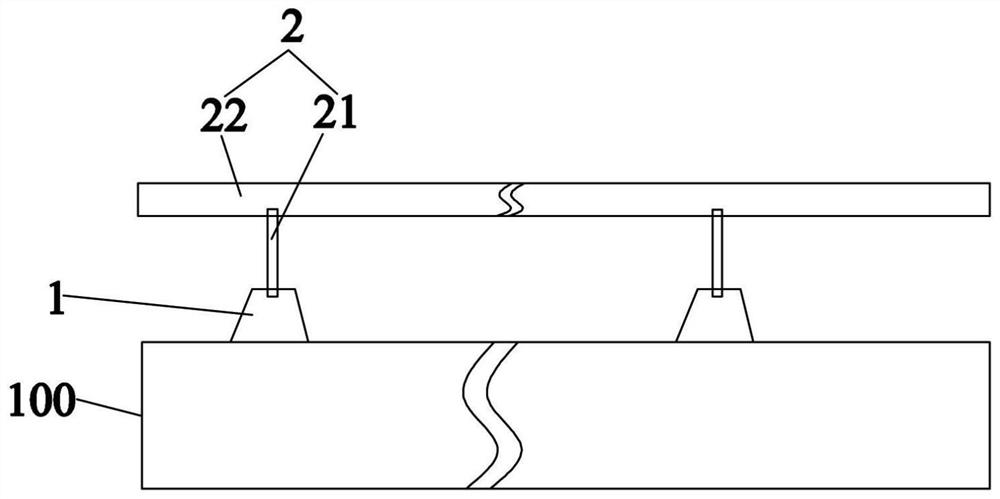

[0047] refer to Figure 1~3 , the present embodiment provides a pole piece winding method, comprising the following steps:

[0048] Coating a thin current collector with a thickness of 20 μm to form a pole piece 100 with a coated area and a non-coated area, after rolling the pole piece 100, die-cut a plurality of trapezoidal tabs 1 on the non-coated area, The height of the tab 1 is 0.1-30cm;

[0049] Connect the anti-folding part 2 on the tab 1, the anti-folding part 2 includes a connecting part 21 and a supporting part 22 connected to each other, the connecting part 21 is connected with the tab 1, and the supporting part 22 is arranged side by side with the pole piece 100; the connecting part 21 is a cylindrical strip, the diameter of the connecting part 21 is 0.05mm~30cm, and the length is 0.5~30cm; the material of the connecting part 21 is PET; the supporting part 22 is a rectangular strip, the width of the supporting part 22 is 0.5~50cm, and the thickness The material of t...

Embodiment 2

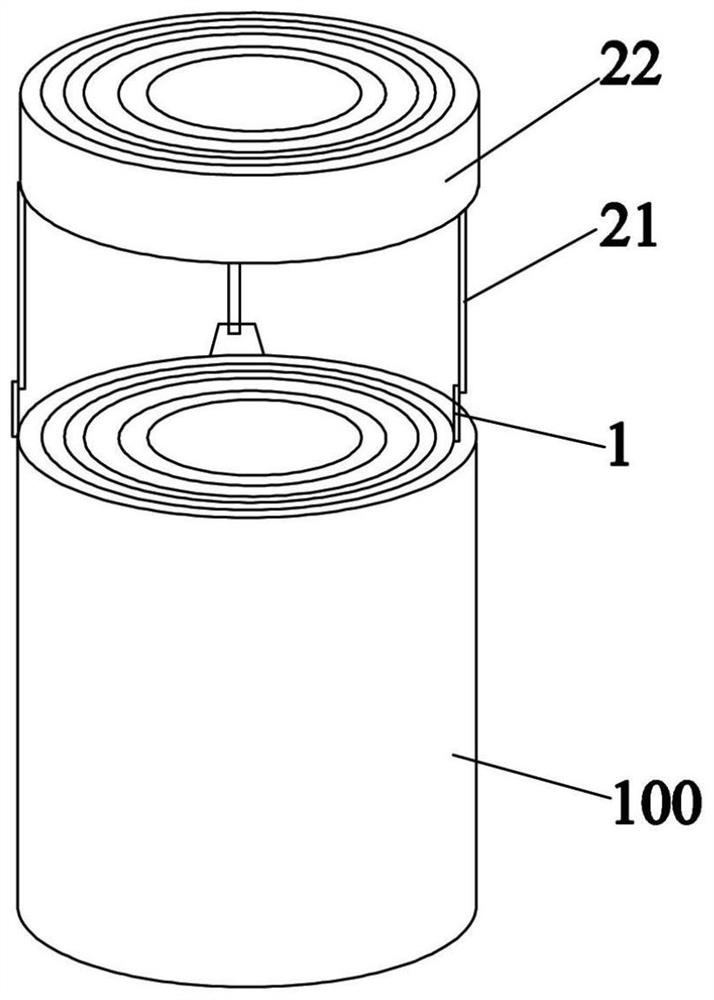

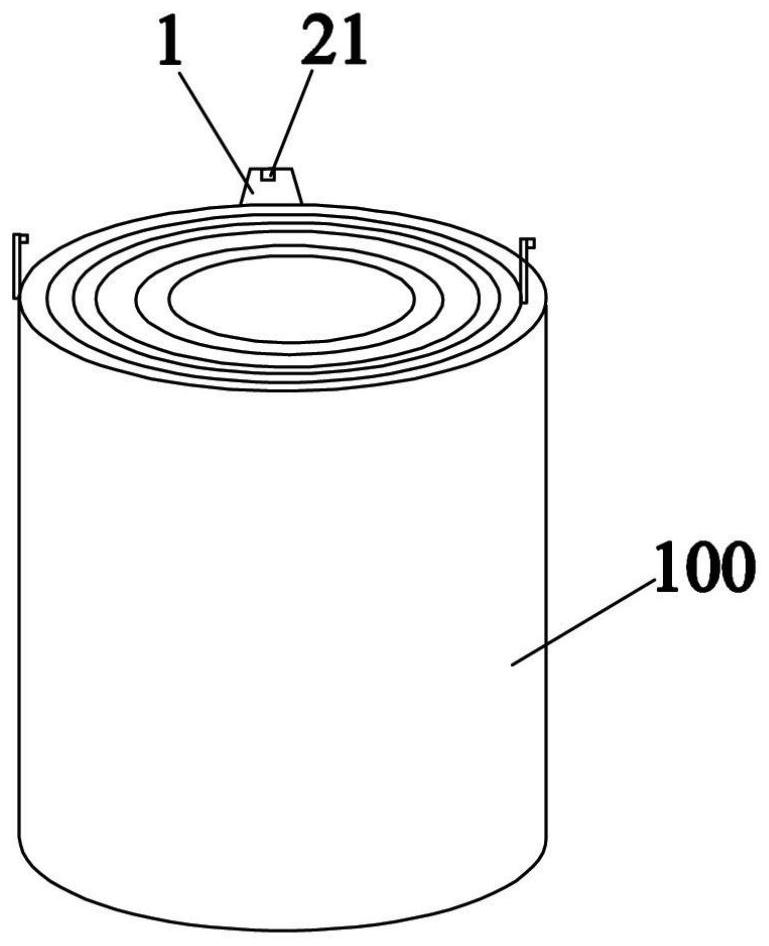

[0052] refer to Figure 4~6 , the difference between this embodiment and embodiment 1 is:

[0053] A plurality of rectangular tabs 1 are die-cut in the non-coating area.

[0054] The connection part 21 is in the shape of a long and narrow strip, and the width of the connection part 21 is 0.05mm-30cm, and the length is 0.5-30cm. Both the connecting portion 21 and the supporting portion 22 are made of aluminum. The connecting part 21 and the supporting part 22 are integrally formed. The end of the connecting portion 21 is connected to the tab 1 by means of adhesion, electric welding or thermal fusion.

[0055] When the pole piece 100 is rolled up to the position close to the tab 1 , it is cut along the end of the connecting portion 21 , and part of the tab 1 is cut off at the same time, so as to disconnect the tab 1 from the anti-folding member 2 .

[0056] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com