Liquid hydrogen production facility and hydrogen gas production facility

A technology for manufacturing equipment and liquid hydrogen, which is applied in lighting and heating equipment, hydrogen, liquefaction, etc., and can solve problems such as carbon dioxide treatment that has not been recorded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

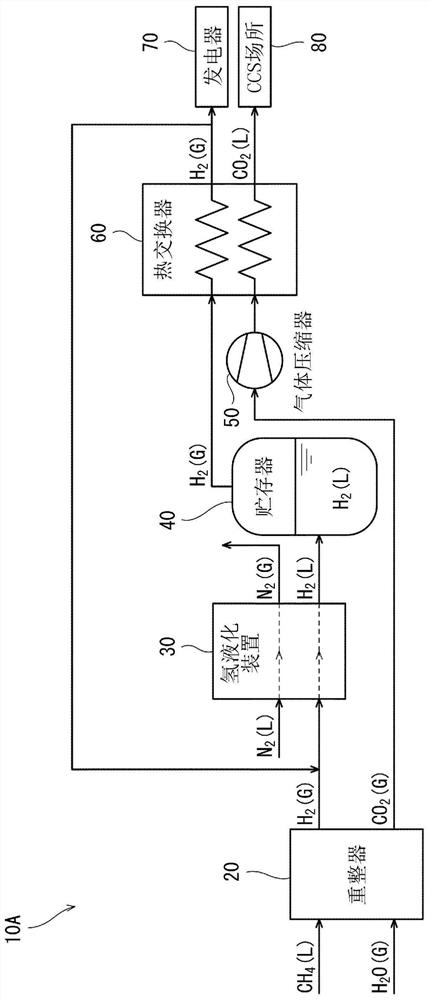

Examples

no. 2 Embodiment approach

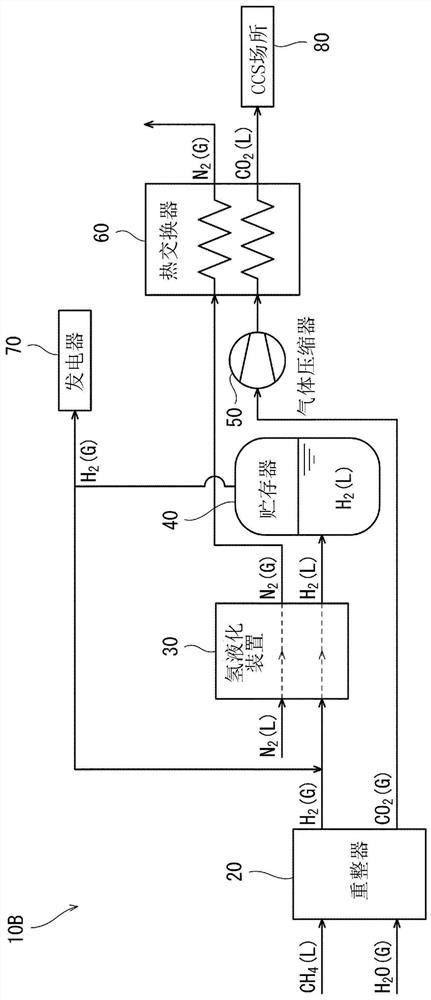

[0048] figure 2 A liquid hydrogen production facility 10B according to a second embodiment of the present invention is shown. In addition, the liquid hydrogen production facility 10B of this embodiment has the same structure as the liquid hydrogen production facility 10A of the above-mentioned first embodiment in many respects. Therefore, the same reference numerals are assigned to the same parts, and the same description will not be repeated.

[0049] In this embodiment, liquid hydrogen H is generated in the hydrogen liquefaction device 30 2 (L) Nitrogen produced during the process N 2 (G) is sent to the heat exchanger 60 . Also, in the present embodiment, the boil-off gas (namely, hydrogen gas H) generated in the reservoir 40 2 (G)) is sent to the flow path toward the hydrogen liquefaction device 30 , or is sent to the generator 70 provided in the liquid hydrogen production facility 10B. Preferably, the boil-off gas is heated to a predetermined temperature and compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com