Transapical mitral valve stitching instrument

A mitral valve and stapler technology, applied in the field of transapical mitral valve stapler, can solve the problems of high surgical risk, unavoidable risk of thrombus and antithrombotic bleeding, and large trauma, so as to achieve fast postoperative recovery and avoid thrombus Formation and bleeding risk, less traumatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

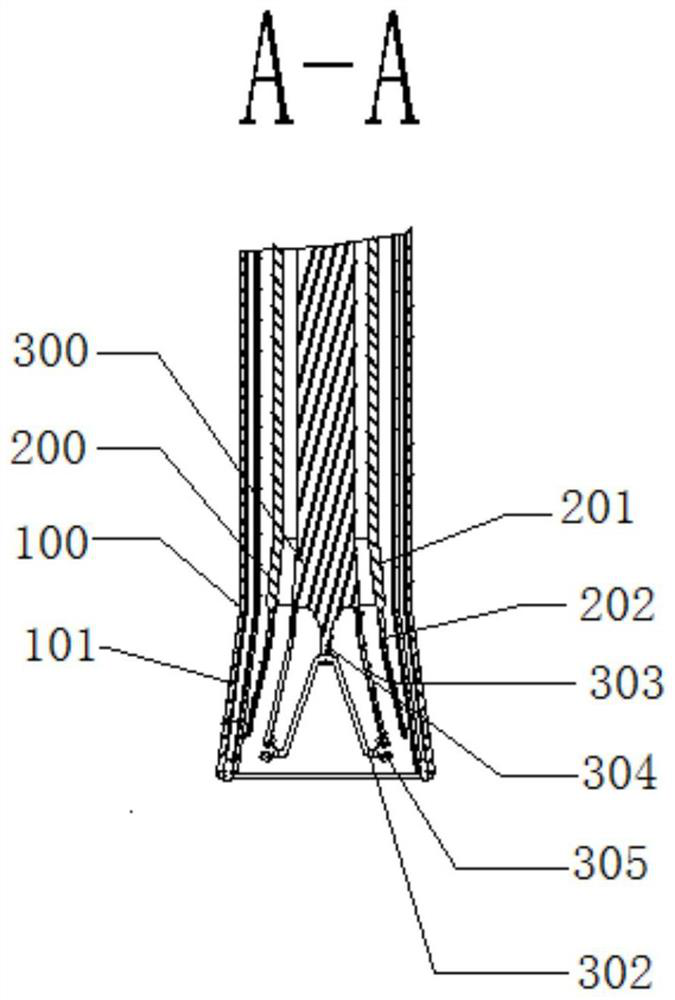

[0030] See Figure 1 to Figure 12 As shown, the transapical mitral valve suture device of the present invention includes an outer sleeve 100, an inner sleeve 200, and an inner sheath 300 nested in sequence from the outside to the inside. The inner sheath 300 includes a sheath body 301 and a pulling wire 302. Elastic valve stoppers 303 are provided on both sides of the bottom. The bottom end of the sheath body 301 extends downwards from the pulling wire fixing rod 304. The inner sleeve 200 includes an inner tube 201. The bottom two sides of the inner tube 201 are provided with elastic valve support sheets 202. , The two sides of the inner tube wall of the outer sleeve 100 are respectively provided with suture pipes 101, the suture pipe 101 is laid with a valve suture with a suture fixing head 102, and the port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com