Ultrasonic-enhanced supercritical fluid extraction method

A supercritical fluid and ultrasonic strengthening technology, applied in the field of extraction, can solve the problems of troublesome cleaning, residue, and inability to separate liquids, and achieve the effects of preventing incomplete extraction and separation, easy cleaning and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

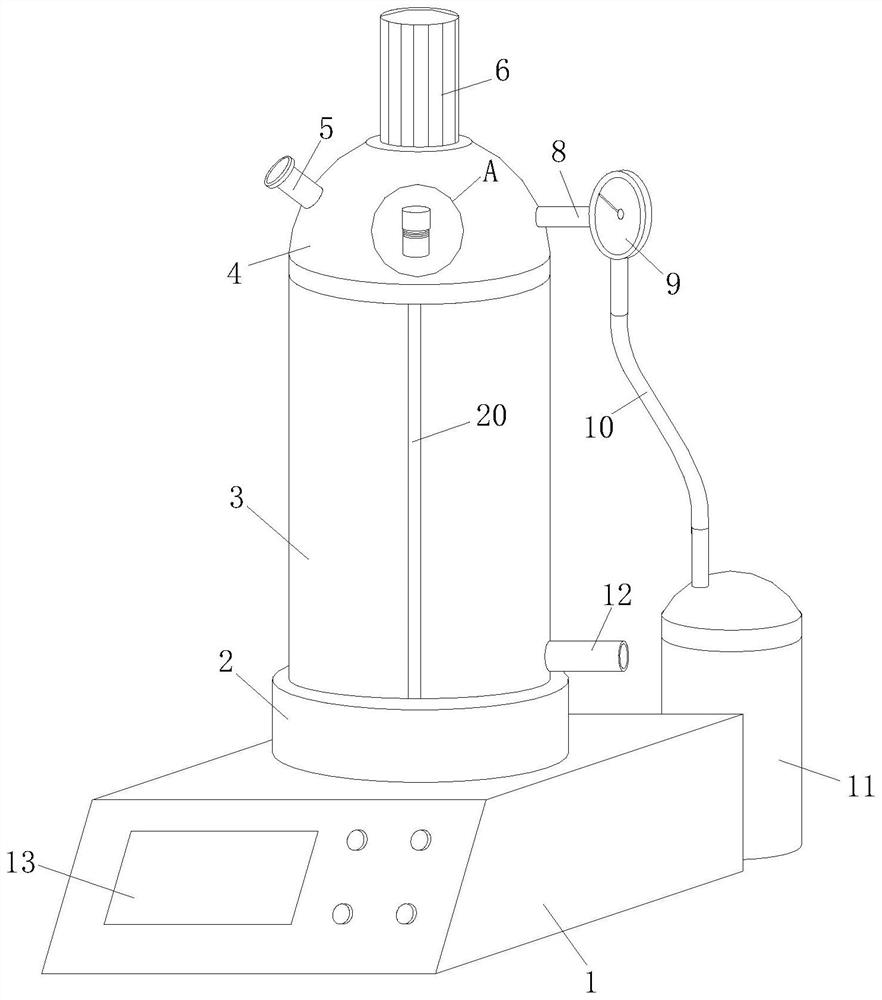

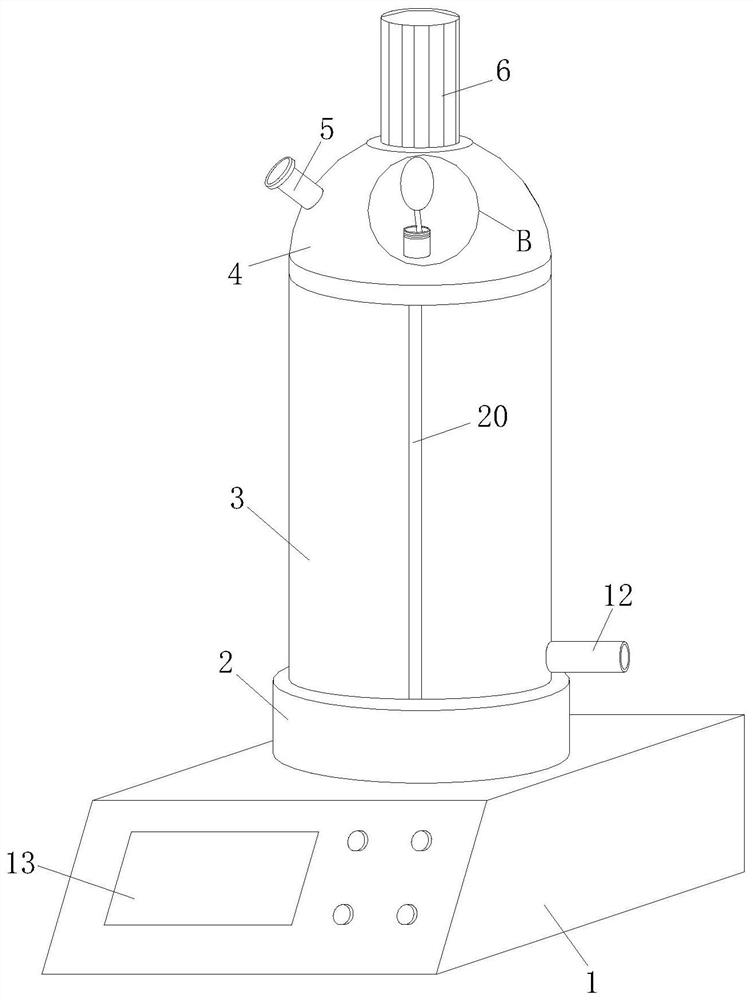

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

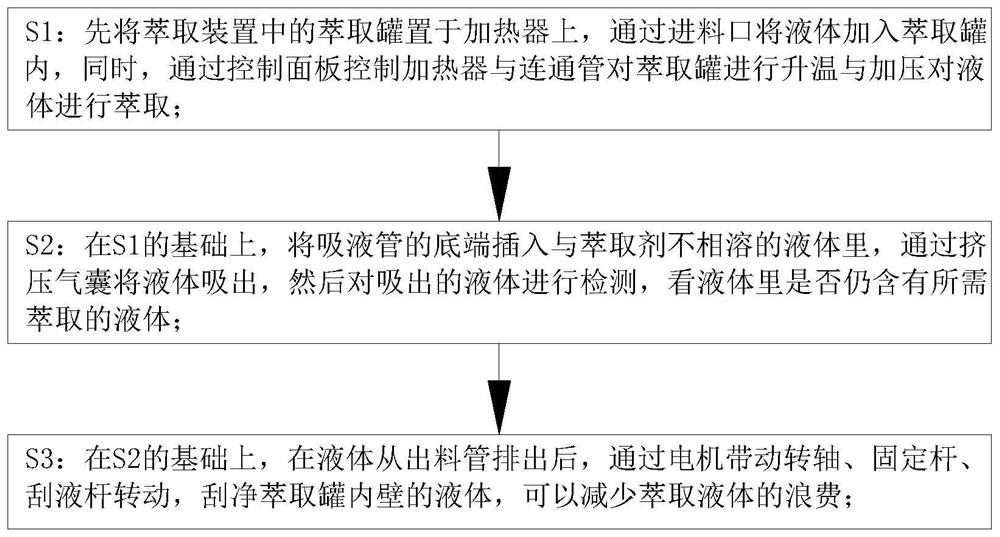

[0028] Such as Figure 1-7 Shown, a kind of ultrasonic strengthening supercritical fluid extraction method, this method comprises the following steps:

[0029] S1: firstly place the extraction tank 3 in the extraction device on the heater 2, and add the liquid into the extraction tank 3 through the feed port 5, and at the same time, control the heater 2 and the connecting pipe 10 through the control panel 13 The liquid is extracted by heating and pressurizing;

[0030] S2: On the basis of S1, insert the bottom end of the suction tube 19 into the liquid that is incompatible with the extractant, suck out the liquid by squeezing the air bag 14, and then test the sucked liquid to see if it still contains the liquid to be extracted;

[0031] S3: On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com