Meat grinder for food processing

A food processing and meat grinder technology, applied in the field of food processing, can solve the problems of meat grinding, moving, and gaps at the extrusion place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 4 Shown:

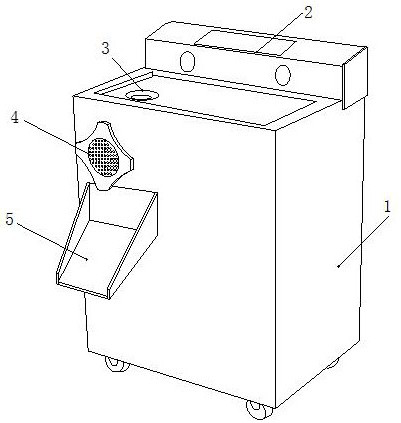

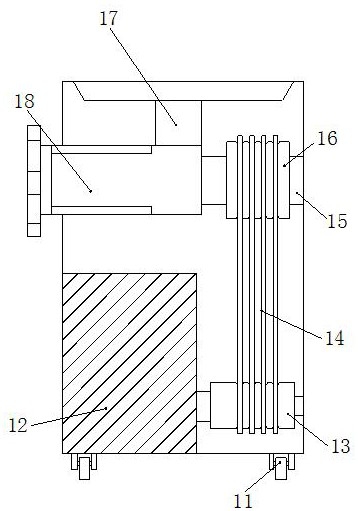

[0025] The invention provides a meat grinder for food processing, the structure of which comprises a meat grinder chamber 1, a control panel 2, a meat outlet 3, an extrusion outlet 4, and a receiving plate 5, the upper end of the meat grinder chamber 1 is welded to the lower end of the control panel 2 Connected, the meat opening 3 is nested and connected with the upper end of the extrusion port 4, the extrusion port 4 is embedded and connected with the front of the meat grinding chamber 1, the receiving plate 5 is located below the extrusion port 4, and the meat grinding chamber 1 includes Roller 11, motor box 12, transmission wheel 13, transmission belt 14, fixed shaft 15, belt pulley 16, meat feeding pipe 17, cylinder 18, described roller 11 is riveted connection with motor box 12 lower ends, described transmission wheel 13 and motor box 12, the right side is clearance fit, the transmission belt 14 is connected betwe...

Embodiment 2

[0031] as attached Figure 5 to attach Figure 7 Shown:

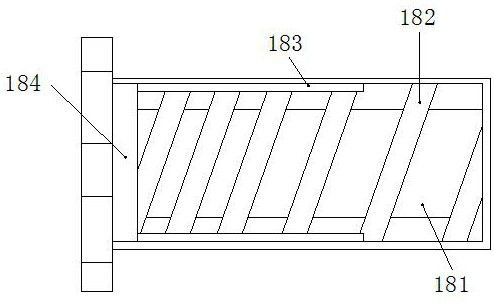

[0032]Wherein, the blade 184 includes a blade 84a, a rivet 84b, a fixed piece 84c, and a protective ring 84d, the blade 84a is welded to the outer side of the protective ring 84d, the rivet 84b is riveted to the front of the fixed piece 84c, and the protective ring 84d cooperates with the outer clearance of blade 84a, and the number of said blades 84a is three, and it is annularly distributed around the fixed piece 84c. The contact angle of the meat material cutting is beneficial to reduce the grinding effect of the blade 84a on the meat material.

[0033] Wherein, the blade 84a includes a main body a1, a replacement knife a2, an initial piece a3, a bottom plate a4, a connecting rod a5, a sliding block a6, a lifting block a7, a shrapnel a8, an inclined block a9, an interchangeable shaft a10, and the lower end of the main body a1 The inner side is in clearance fit with the lower side of the initial piece a3, the repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com