Flat tube and fin clamping and pressing device, manufacturing method and micro-channel heat exchanger

A fin card and micro-channel technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigerators, etc., can solve the problem of reducing heat transfer efficiency, affecting the heat transfer performance of fins, and the tightness of fins and flat tubes and other problems, to achieve the effect of improving product quality, strong versatility, and stabilizing the position of flat tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments of the present invention.

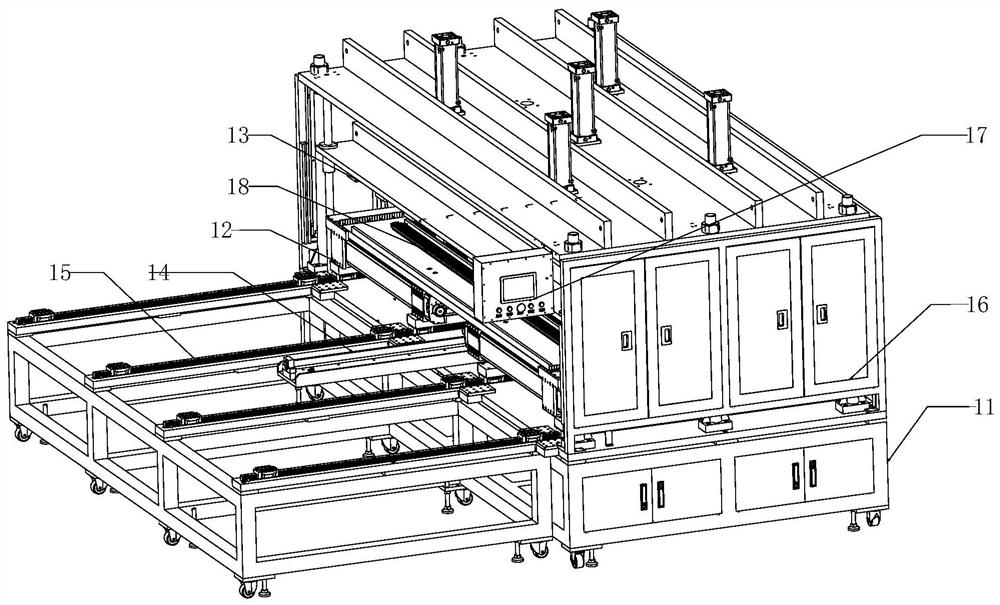

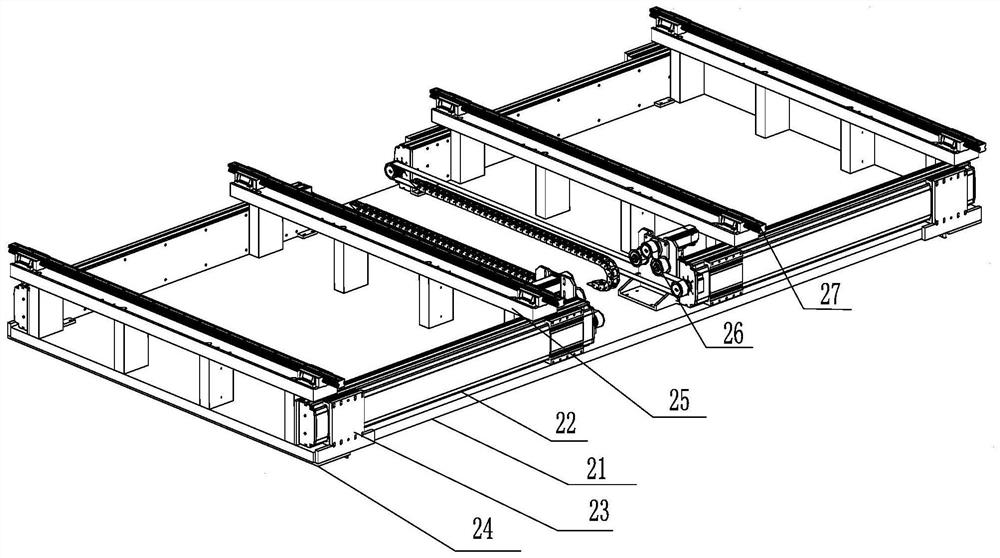

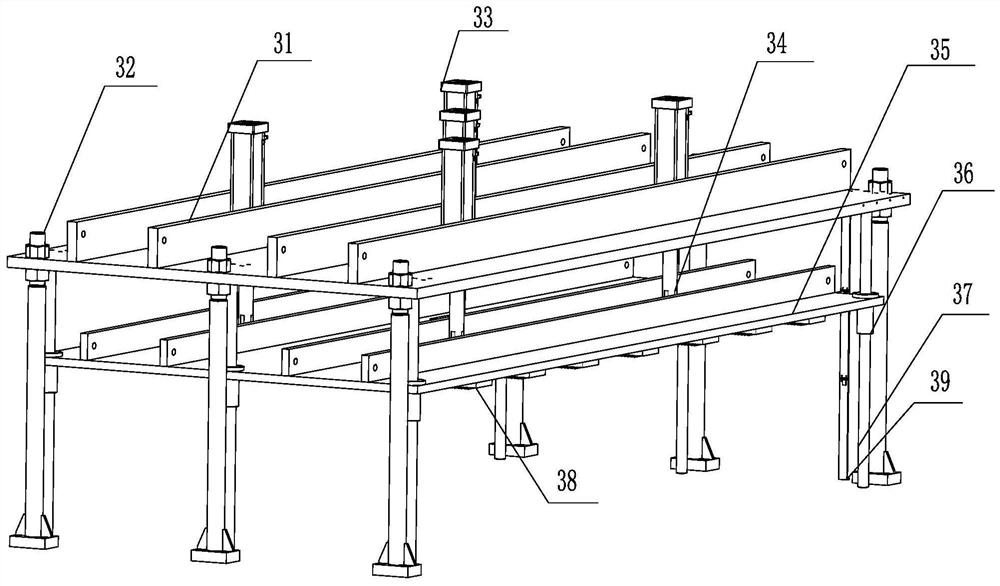

[0045] figure 1 It is a structural schematic diagram of the clamping and pressing device of the flat tube and the fin according to the embodiment of the present invention; figure 2 It is a schematic structural diagram of the transfer platform assembly 12 according to the embodiment of the present invention; image 3 It is a structural schematic diagram of the press assembly 13 according to the embodiment of the present invention.

[0046] Such as Figure 1 ~ Figure 3 As shown, the clamping and pressing device of the microchannel flat tube and the fin includes a first frame 11, a transfer platform assembly 12, a press assembly 13, a transfer module 14, a second frame 15, and a protective cover 16 and the control panel 17 . in:

[0047] The press assembly 13 is assembled on the first frame 11, and the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com