Garbage classification damping delivery port for railway vehicle

A technology for garbage classification and rail vehicles, applied in trash cans, garbage collection, vehicle components, etc., can solve the problems of loud noise and resistance of garbage classification delivery ports, and achieve the effect of reducing noise, convenient use for passengers and avoiding injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

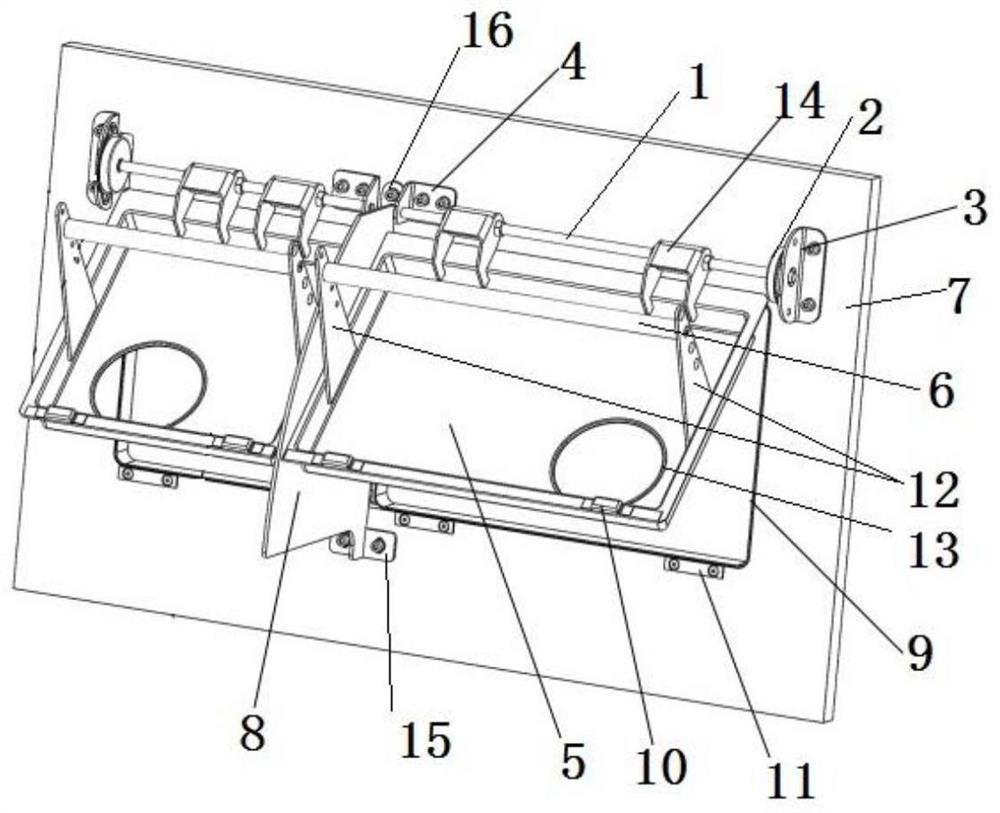

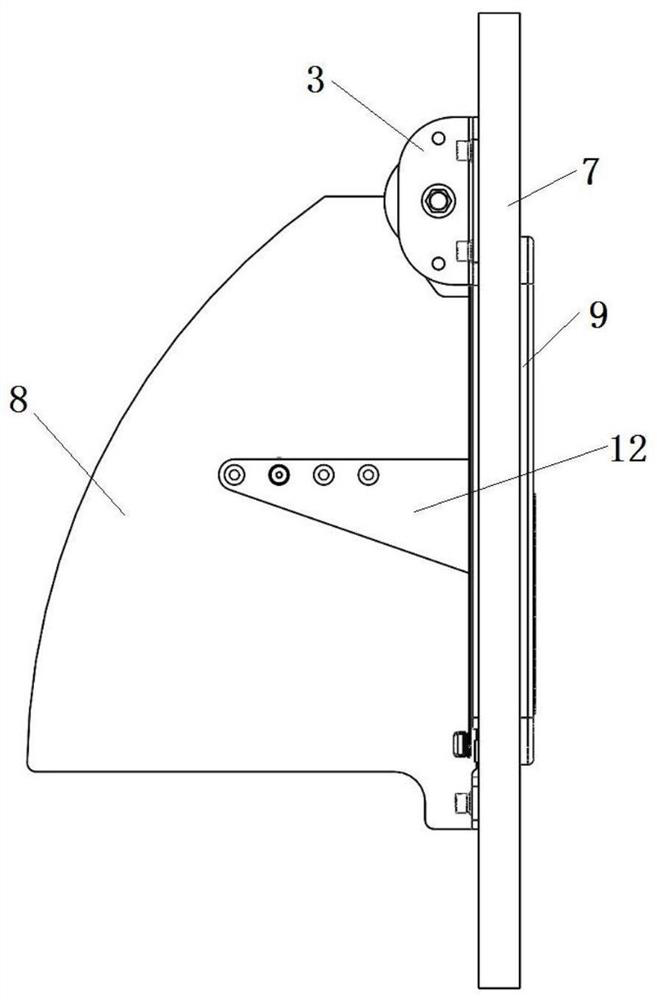

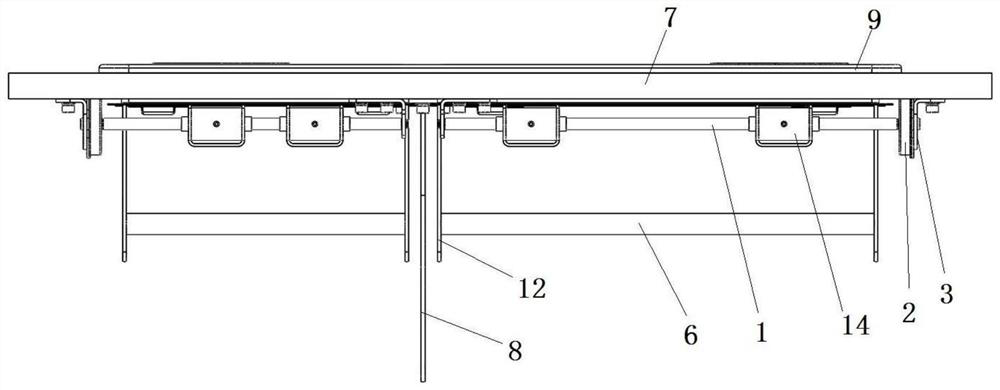

[0022] refer to figure 2 The specific embodiment of the present invention is to provide a kind of garbage sorting damping delivery port for rail vehicles. Two damping delivery ports for putting different types of garbage are arranged side by side on the door panel of the garbage bin. Each damping delivery port includes a rotating shaft 1, a one-way rotation damping Device 2, mounting seat 4, delivery port panel 5, counterweight bar 6. One end of the rotating shaft 1 is connected to the one-way rotation damper 2, and the other end is connected to the installation seat 4. The one-way rotation damper 2 is provided with a damper seat 3, and the damper seat 3 and the installation seat 4 are installed on the dustbin with screws. On the door panel 7. The lower part of the rotating shaft 1 is welded to the upper side of the delivery port panel 5 through the hanging claw 14. The delivery port panel 5 is a box-shaped structure opening toward the inside of the garbage bin, and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com