A solid-liquid separation trash can for municipal environmental protection

A technology of solid-liquid separation and trash cans, which is applied in the field of trash cans to achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

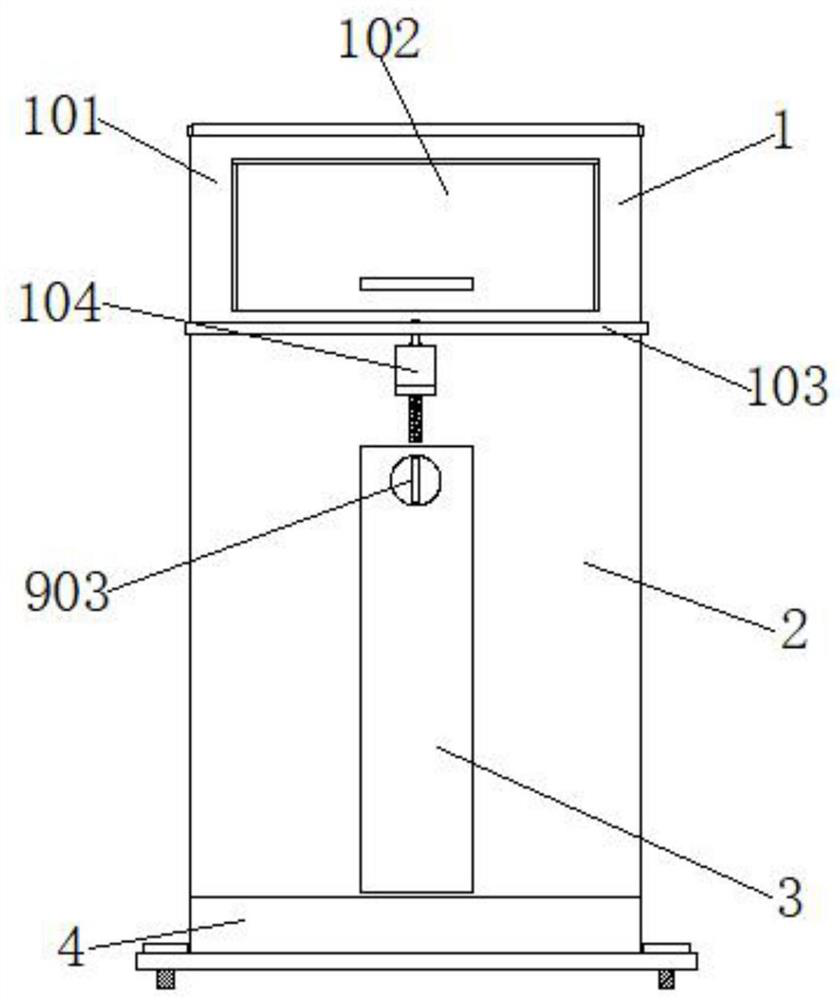

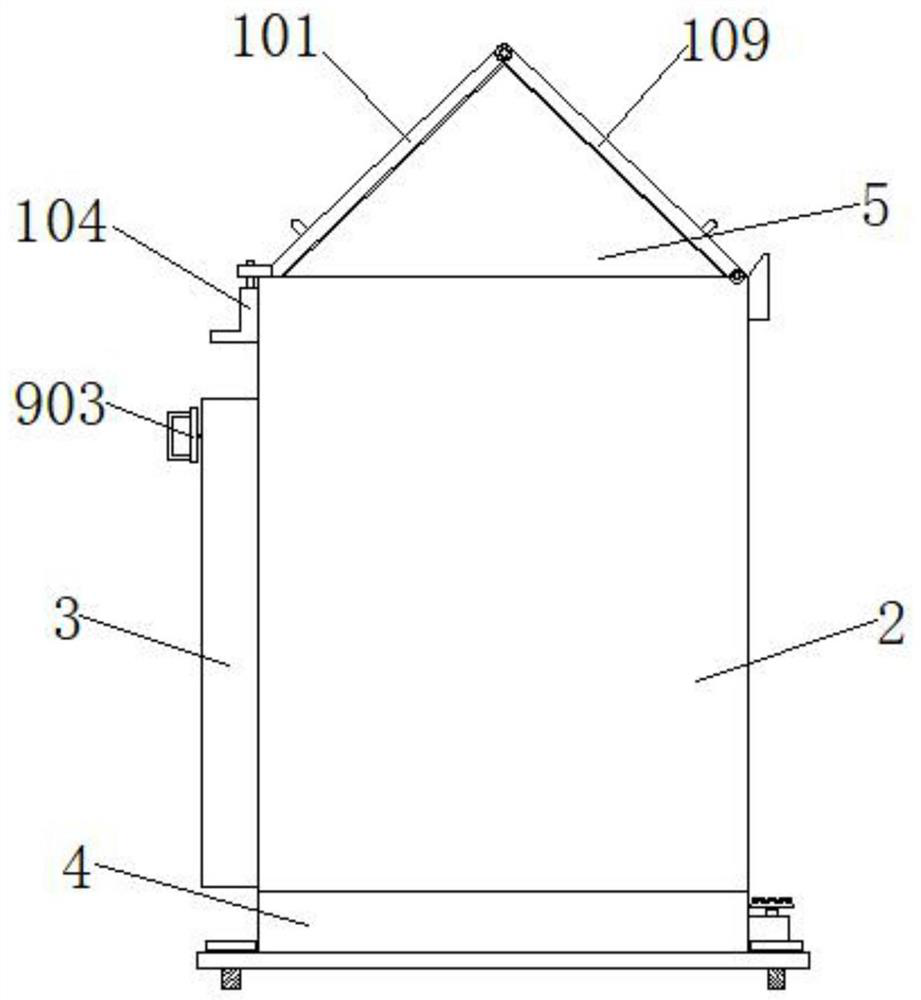

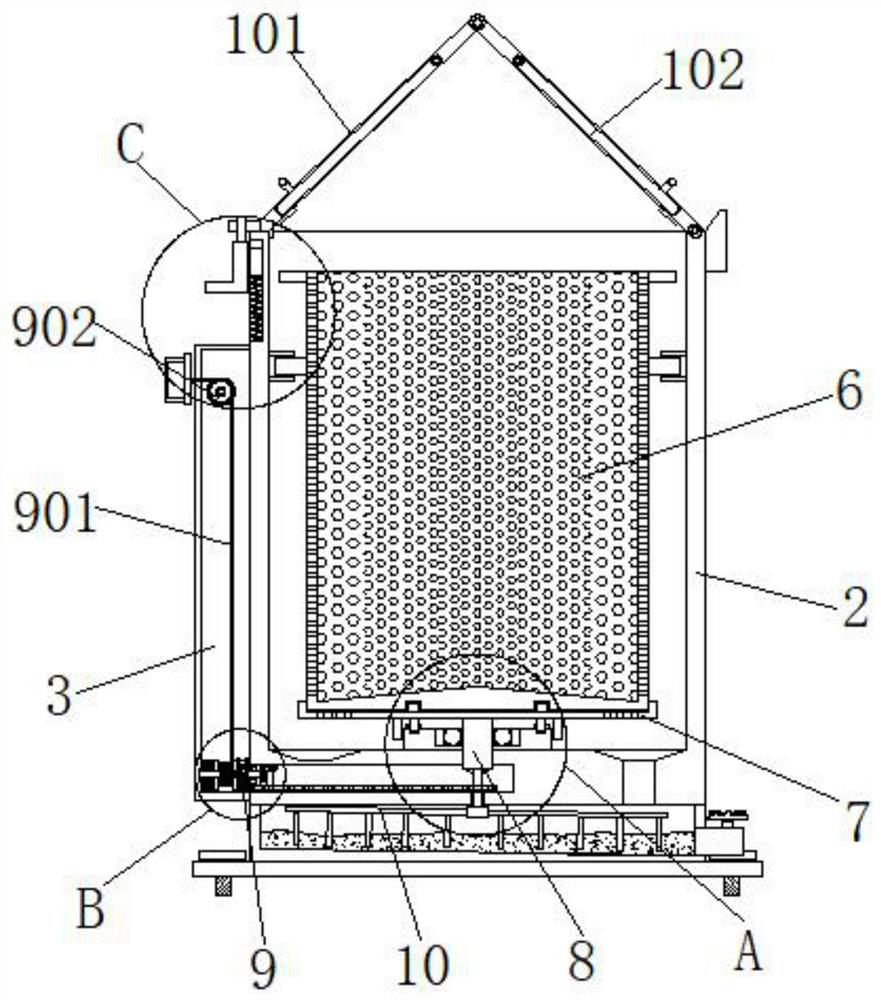

[0035] Example 1, as Figure 1-7 As shown, before cleaning the garbage inside the trash can 6, first manually pull the pull rope 901 to the outside of the installation bin 3 through the handle 903, thereby driving the spool 904 to rotate clockwise on the outside of the rotating shaft B906, at this time the coil spring 907 is gradually wound up to store a certain amount of kinetic energy, and because the one-way gear A910 and the one-way gear B25 are in a clamped state, the rotating shaft D21 is driven to follow the rotation. Drive the rotating shaft E24 to rotate, the rotating shaft E24 is driven by the pulley 14 and the belt 19, so that the rotating shaft C13 and the rotating shaft A8 move and follow the rotation, and the rotating shaft A8 drives the turntable 7 and the trash can 6 on the top of the turntable 7 to rotate, and the centrifugal force generated during the rotation of the trash can 6 The liquid that still exists in the garbage is forced to be thrown out, and when ...

Embodiment 2

[0036] Example 2, as Figure 1-8 As shown in the figure, when the garbage inside the trash can 6 is cleaned, the hand push plate 104 is manually pushed down to release the limiting effect on the cover plate A101, and then the cover plate A101 and the cover plate B109 are bent and overlapped, and the The cover plate A101 and the cover plate B109 are rotated and moved to the end away from the installation bin 3, and the upper part of the main body box 2 is completely exposed, so that the cleaning personnel can take out the trash can 6 from the main body box 2 and dump the garbage, and then pass the garbage to the main body box. The inside of 2 is flushed with clean water, and the rotating shaft C13 is rotated by manually pulling the pull rope 901. During the rotation of the rotating shaft C13, the rotating shaft C13 drives the installation rod 10 and the stirring rod 18 inside the liquid storage tank 4 to rotate together, so that the stirring rod 18 rotates together. The sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com