Solvothermal pretreatment method and application of waste lithium battery positive electrode material

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of solvothermal pretreatment of waste lithium battery positive electrode materials, can solve problems such as not being universal, and achieve the effects of universal applicability, low cost, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

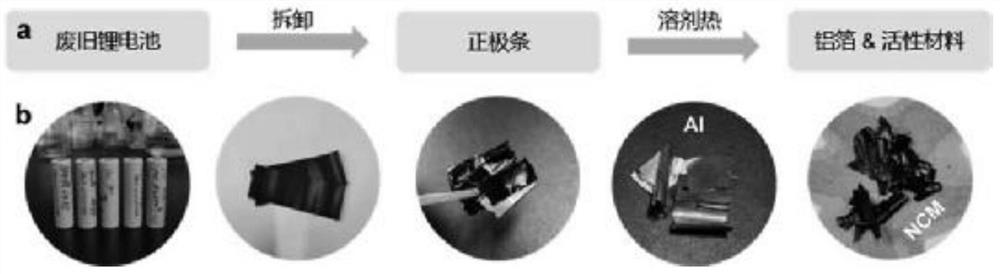

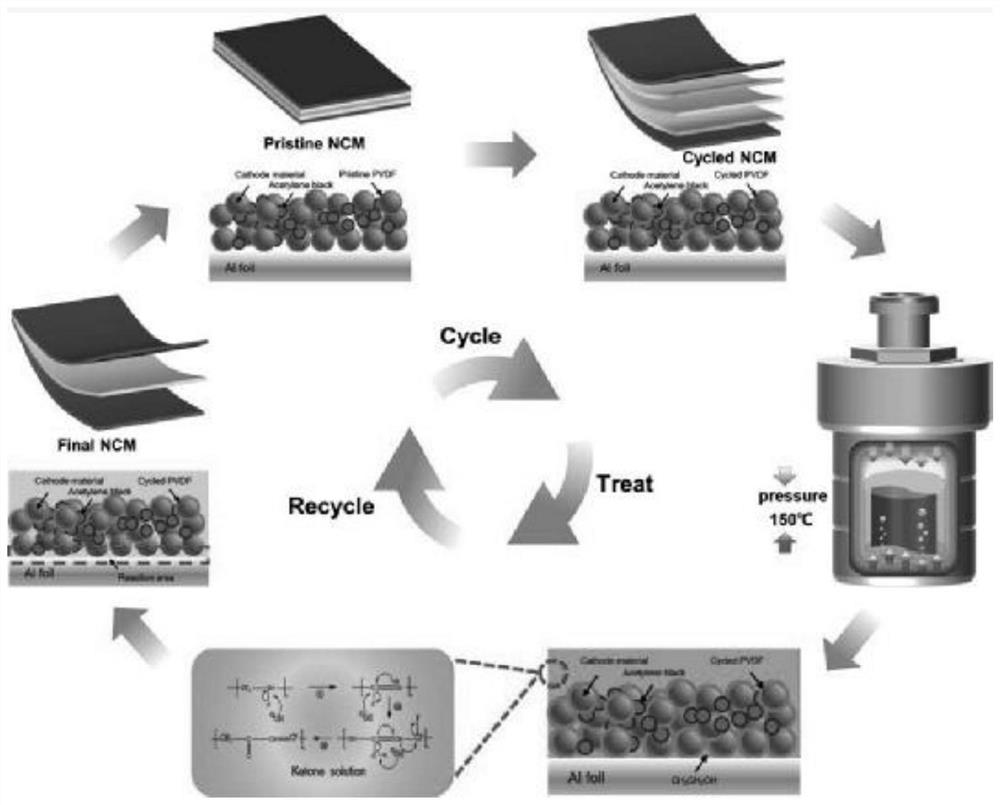

[0055] A solvothermal pretreatment method for waste lithium battery cathode materials, comprising the steps of:

[0056] Step S1, soak the positive electrode strip obtained by dismantling the waste commercial battery NCM523 with DMC, remove the residual electrolyte on the surface, then take it out, and put it into a blast drying oven to dry;

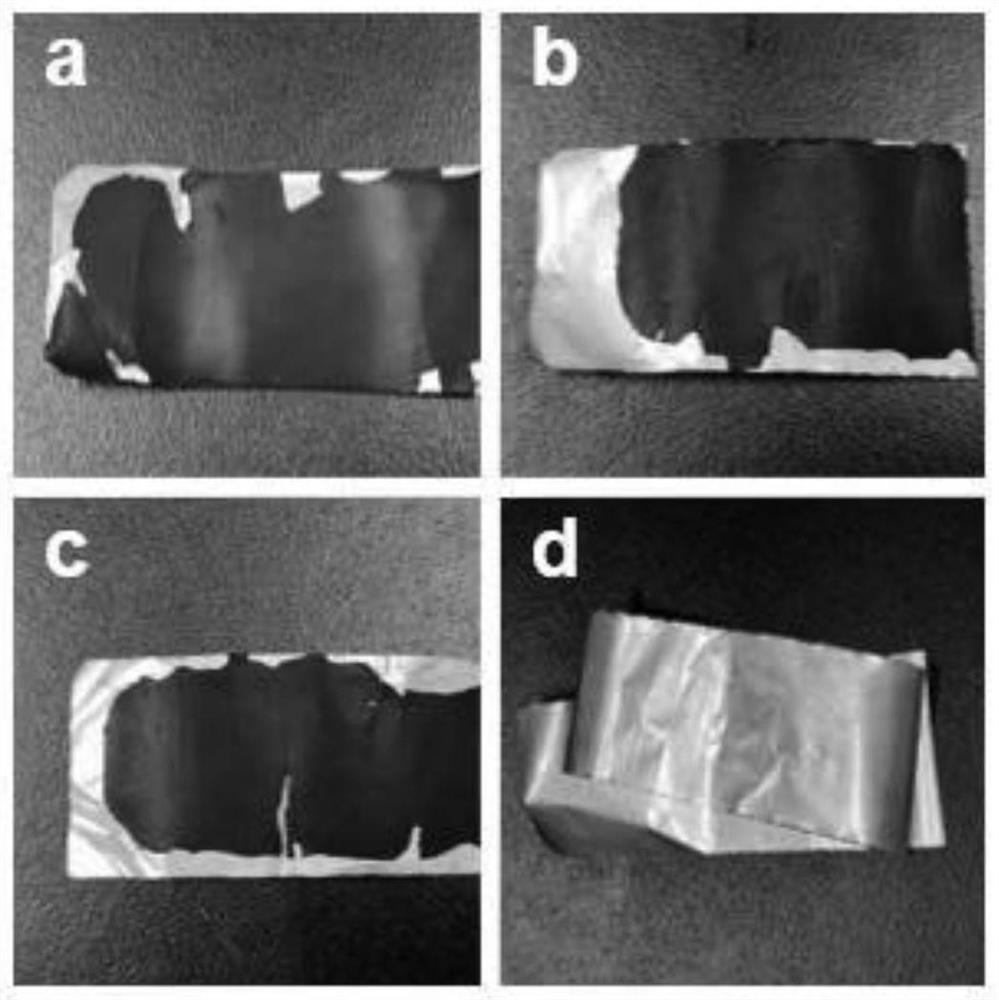

[0057] Step S2, cut the dried positive electrode strips into small strips, divide them into 4 parts on average, put them into the reaction kettle respectively, pour the ethanol solution, the volume ratio of the solution to the waste positive electrode strips is 2:1, and completely immerse the positive electrode strip. Put the reaction kettles into blast drying ovens at different temperatures (120°C, 130°C, 140°C and 150°C) and keep warm for 1 hour;

[0058] In step S3, the cooled reaction vessel is opened, the positive electrode strip is clamped out with tweezers, and the stripped positive electrode material is separated by hand.

Embodiment 2

[0060] A solvothermal pretreatment method for waste lithium battery cathode materials, comprising the steps of:

[0061] Step S1, soak the positive electrode strip obtained by dismantling the waste commercial battery NCM811 with DMC, remove the residual electrolyte on the surface, then take it out, and put it into a blast drying oven to dry;

[0062] Step S2, cut the dried positive electrode strips into small strips, put them into the reaction kettle, pour N-N dimethylformamide solution, the volume ratio of the solution to the waste positive electrode strips is 1:1, make it just submerge the positive electrode strips . Put the reaction kettle into a blast drying oven, and keep it warm for 1.5 hours at a temperature of 150°C.

[0063] In step S3, the cooled reaction kettle is opened, the positive electrode strip is clamped out with tweezers, and the positive electrode material can be separated from the aluminum foil as a whole by hand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com