A2B2O7 type rare earth tantalate ceramics and preparation method thereof

A technology of A2B2O7 and tantalate, applied in the field of thermal barrier coatings, can solve problems such as lack of B-site regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

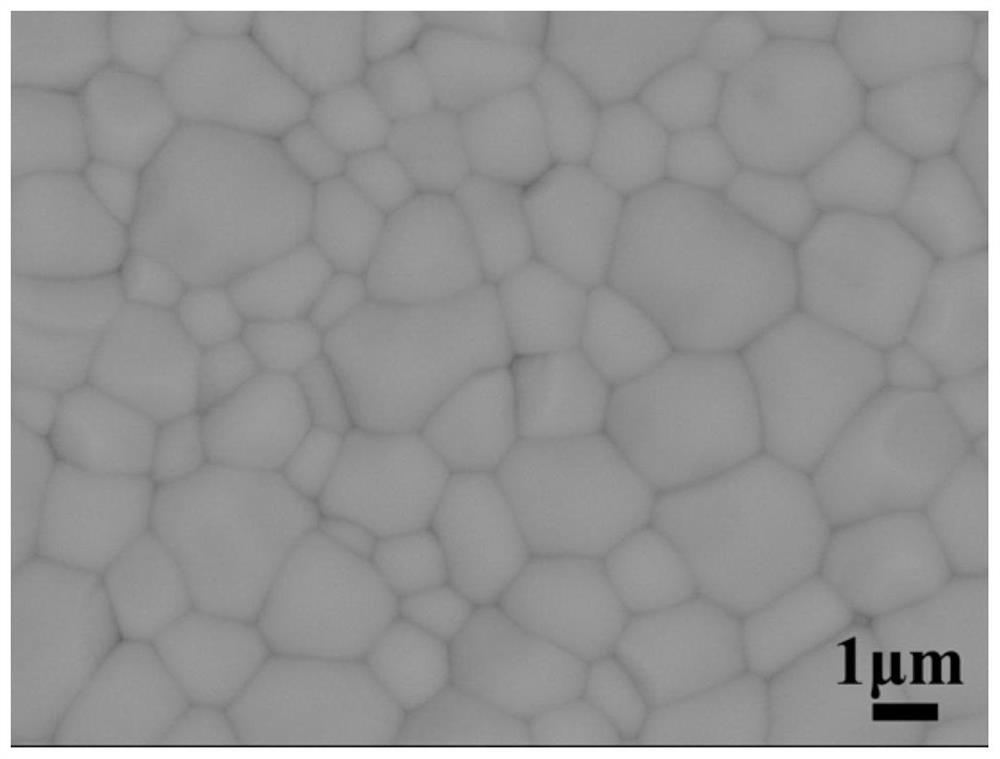

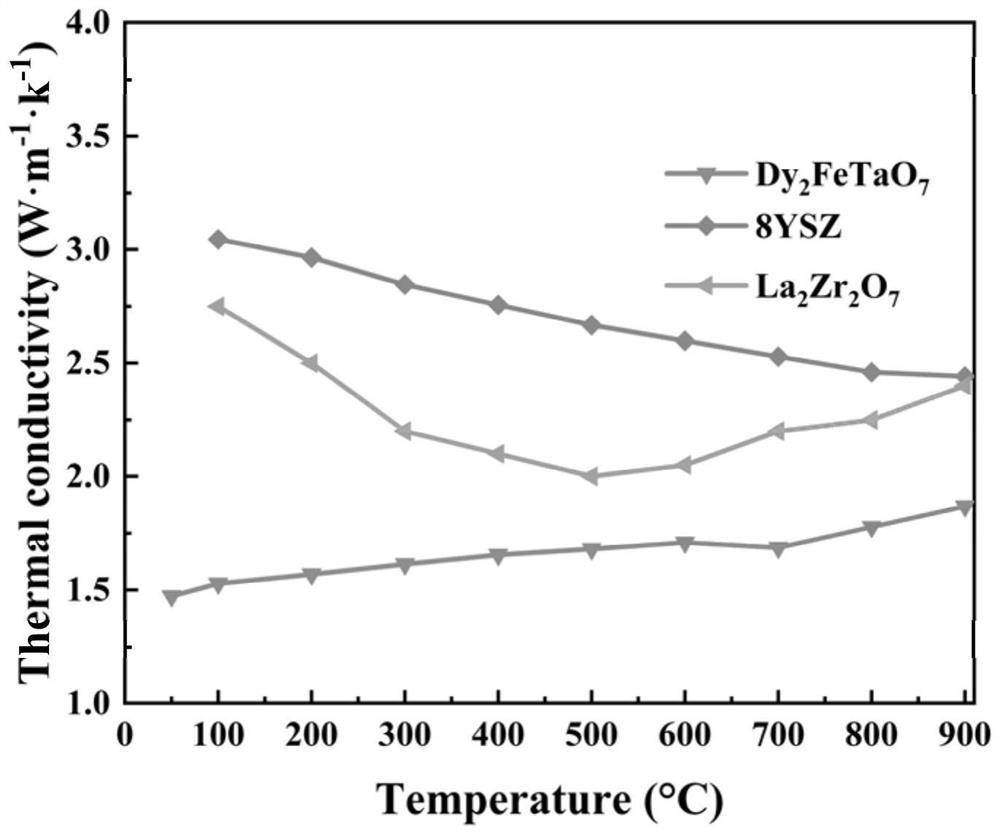

Image

Examples

Embodiment 1

[0034] A 2 B 2 o 7 type rare earth tantalate ceramics, the structure of which is Y 2 FeTaO 7 , the preparation method of the ceramics comprises the following steps:

[0035]Step 1: Follow Y 2 FeTaO 7 The structural formula will be the appropriate amount of Y 2 o 3 and Fe 2 o 3 respectively dissolved in concentrated nitric acid for reaction, and the pH was adjusted to about 1, and then the prepared TaOCl 3 The solution was added dropwise (the speed of dropping was 200mL / min), stirring constantly, adding ammonia water to stabilize the pH of the system at 9~10, after stirring for 1 hour, continue stirring for 30min in a 100°C water bath environment, and then use Wash the precipitate with deionized water continuously until pH = 7, place the obtained filter cake in an oven for 5 hours at 120°C, then pass through a 500-mesh sieve and sinter at 900°C for 5 hours, and the sintered powder is again Pass through a 500 mesh sieve for later use.

[0036] Step 2: Place the powde...

Embodiment 2

[0039] The difference from Example 1 is that the ceramic structural formula of Example 2 is Dy 2 FeTaO 7 , the preparation method of the ceramics is the same as in Example 1.

Embodiment 3

[0041] The difference from Example 1 is that the ceramic structural formula in Example 3 is Eu 2 AlTaO 7 , the preparation method of the ceramics is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap