Process for recycling precious metals

A precious metal and process technology, applied in the field of precious metal recycling and reuse technology, can solve problems such as waste, damage to ceramic packaging shells, and low efficiency of precious metal recycling and reuse, and achieve the effect of reducing costs and recycling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

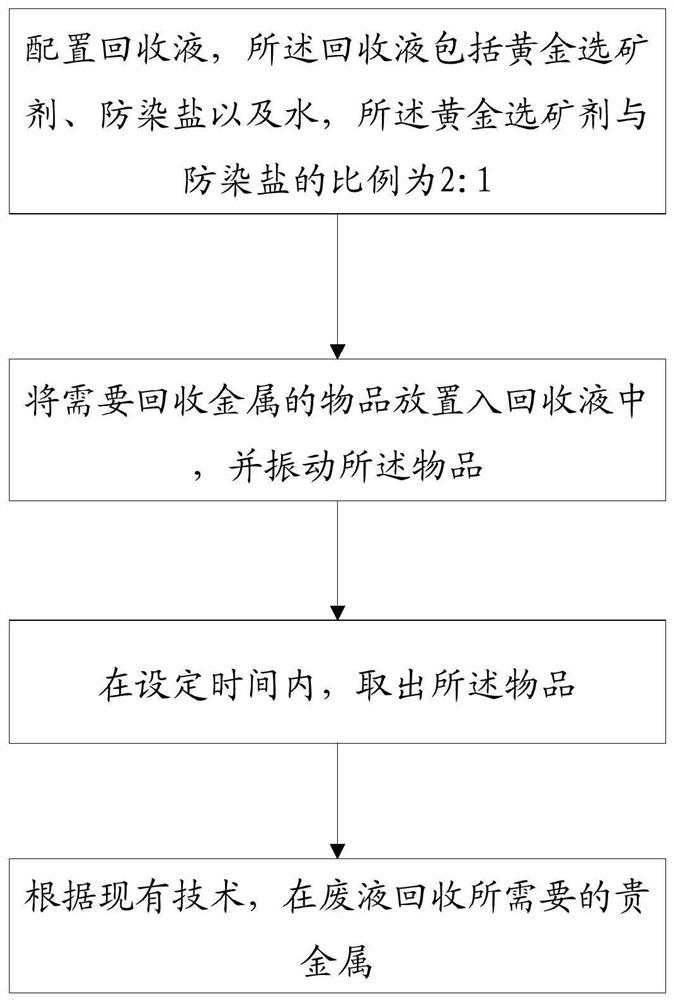

[0023] The present embodiment is used for withdrawing gold or silver or nickel, and specifically includes the following steps:

[0024] Configure the recovery solution, take an appropriate amount of water, choose 60g of gold dressing agent per liter of water, and 30g of anti-staining salt, mix them and fully react, filter out insoluble substances, and move to the recovery tank for use. The pH of the recovery solution is 12 .

[0025] Place the items that need to be recycled into the rolling basket. The items that need to be recovered are ceramic packaging shells, and the ceramic packaging shells are plated with 2 micron thick gold;

[0026] Put the items that need to recover metal in the rolling basket, immerse the rolling basket in the recovery liquid, wait until the recovery liquid submerges the items that need to recover metal, roll slowly and fully contact the recovery liquid, after 3 to 10 minutes, you can After the gold recovery is completed, take out the items that nee...

Embodiment 2

[0029] The present embodiment is used for withdrawing gold or silver or nickel, and specifically includes the following steps:

[0030] Configure the recovery solution, take an appropriate amount of water, choose 75g of gold dressing agent per liter of water, and 37.5g of anti-staining salt, mix them and fully react, filter out the insoluble matter, and move to the recovery tank for use. The pH of the recovery solution is 12.

[0031] Place the items that need to be recycled into the rolling basket. The items that need to be recovered are ceramic packaging shells, and the ceramic packaging shells are plated with 2 micron thick gold;

[0032] Put the items that need to recover metal in the rolling basket, immerse the rolling basket in the recovery liquid, wait until the recovery liquid submerges the items that need to recover metal, roll slowly and fully contact the recovery liquid, after 3 to 10 minutes, you can After the gold recovery is completed, take out the items that ne...

Embodiment 3

[0035] The present embodiment is used for withdrawing gold or silver or nickel, and specifically includes the following steps:

[0036] Configure the recovery solution, take an appropriate amount of water, choose 90g of gold dressing agent per liter of water, and 45g of anti-staining salt, mix them and fully react, filter out insoluble substances, and move to the recovery tank for use. The pH of the recovery solution is 12 .

[0037] Place the items that need to be recycled into the rolling basket. The items that need to be recovered are ceramic packaging shells, and the ceramic packaging shells are plated with 2 micron thick gold;

[0038] Put the items that need to recover metal in the rolling basket, immerse the rolling basket in the recovery liquid, wait until the recovery liquid submerges the items that need to recover metal, roll slowly and fully contact the recovery liquid, after 3 to 10 minutes, you can After the gold recovery is completed, take out the items that nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com