High-strength lightweight porous concrete and preparation method thereof

A porous concrete and concrete technology, applied in the field of concrete, can solve the problems of low strength, decreased drainage capacity, low strength of porous concrete, etc., and achieve the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

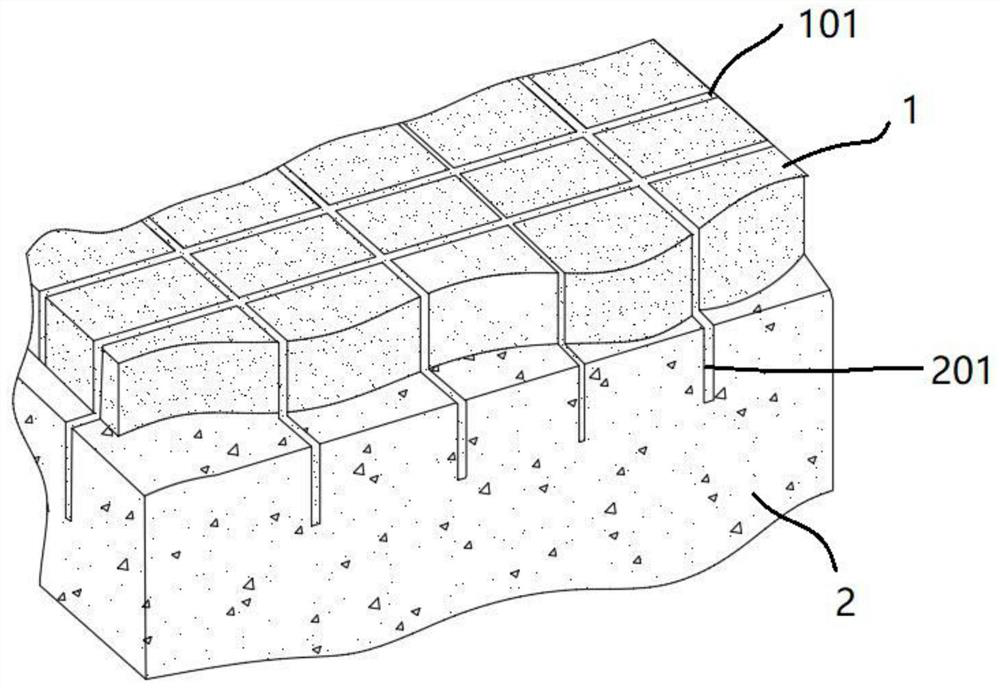

Image

Examples

Embodiment 1

[0044] A method for high-strength lightweight porous concrete, the method comprising the following steps:

[0045] S1. Prepare to receive a flat substrate for pouring concrete mixture. The substrate can be a flat road surface or the lower part of a mold. The mold is generally a cube-shaped mold with a flat lower surface and an opening on the upper part. The opening can Closure causes the mold to form a closed cube.

[0046] S2. Pouring a permeable concrete mixture on the substrate to form a layer of permeable concrete and form a permeable concrete surface;

[0047] S21. Utilize existing concrete blocks to prepare raw materials, specifically:

[0048] S211. Select waste concrete blocks, add them into a high-temperature furnace, and continue to process them at 120° C. for 30 minutes. The exhaust gas concrete block is generally directly selected from the demolished construction site. After removing the internal steel bars, it is placed in a high-temperature furnace for heating....

Embodiment 2

[0063] A method for high-strength lightweight porous concrete, the method comprising the following steps:

[0064] S1. Prepare to receive a flat substrate for pouring concrete mixture. The substrate can be a flat road surface or the lower part of a mold. The mold is generally a cubic mold with a flat lower surface and an opening on the upper part. The opening can Closure causes the mold to form a closed cube.

[0065] S2. Pouring a permeable concrete mixture on the substrate to form a layer of permeable concrete and form a permeable concrete surface;

[0066] S21. Utilize existing concrete blocks to prepare raw materials, specifically:

[0067] S211. Select waste concrete blocks, add them into a high-temperature furnace, and continue to process them at 130° C. for 35 minutes. The exhaust gas concrete block is generally directly selected from the demolished construction site. After removing the internal steel bars, it is placed in a high-temperature furnace for heating. The p...

Embodiment 3

[0082] A method for high-strength lightweight porous concrete, the method comprising the following steps:

[0083] S1. Prepare to receive a flat substrate for pouring concrete mixture. The substrate can be a flat road surface or the lower part of a mold. The mold is generally a cubic mold with a flat lower surface and an opening on the upper part. The opening can Closure causes the mold to form a closed cube.

[0084] S2. Pouring a permeable concrete mixture on the substrate to form a layer of permeable concrete and form a permeable concrete surface;

[0085] S21. Utilize existing concrete blocks to prepare raw materials, specifically:

[0086] S211. Select waste concrete blocks, add them into a high-temperature furnace, and continue to process them at 150° C. for 45 minutes. The exhaust gas concrete block is generally directly selected from the demolished construction site. After removing the internal steel bars, it is placed in a high-temperature furnace for heating. The p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap