Formwork and construction method for construction joints of pipe gallery wall

A technology of construction joints and walls, applied in the field of building foundations, to achieve the effects of flexible operation, enhanced construction effect, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

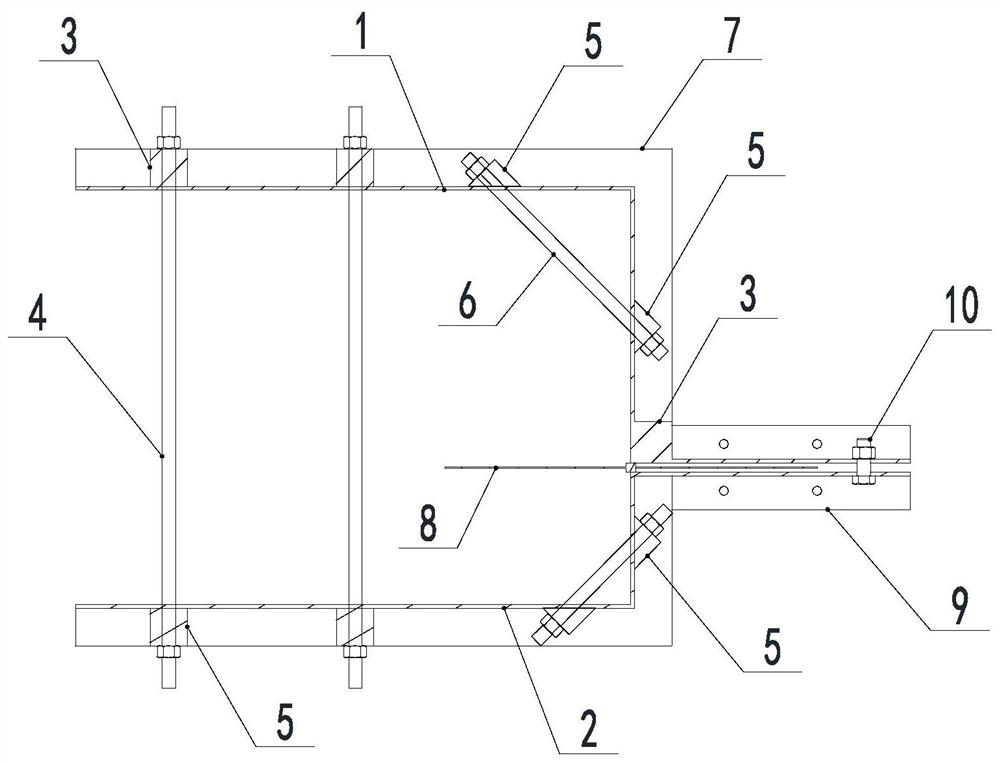

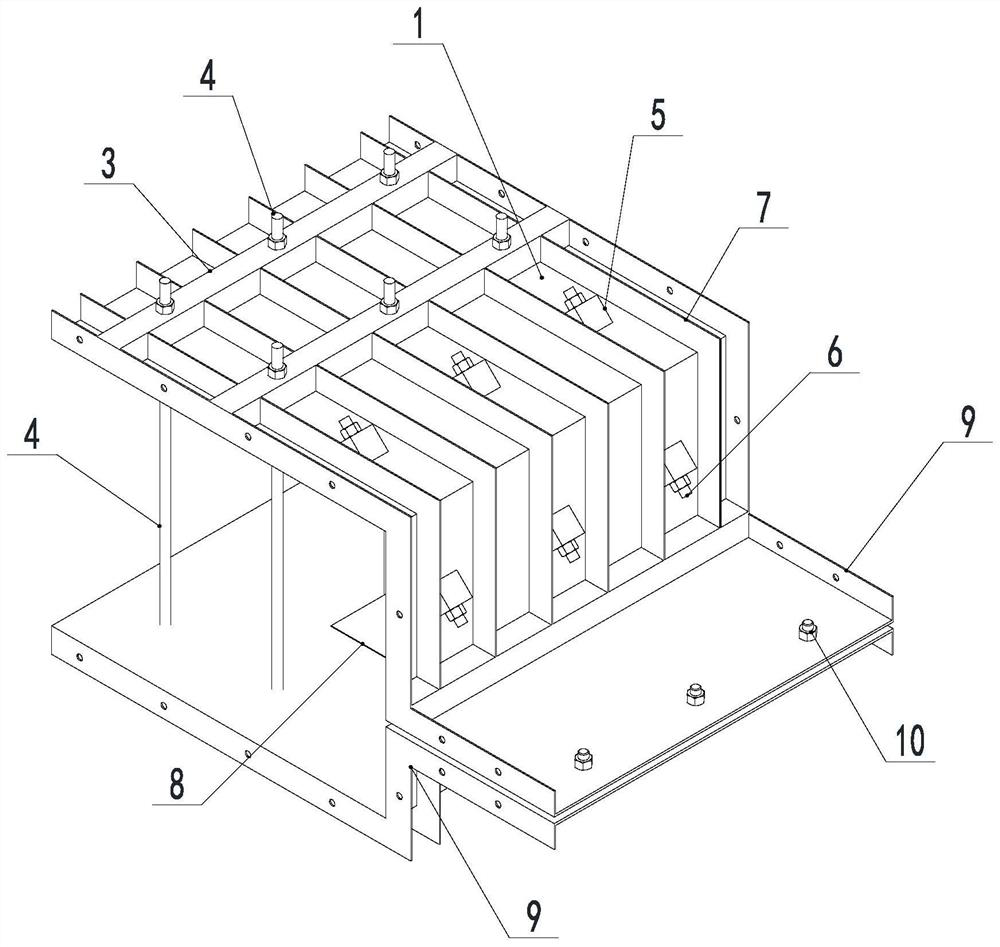

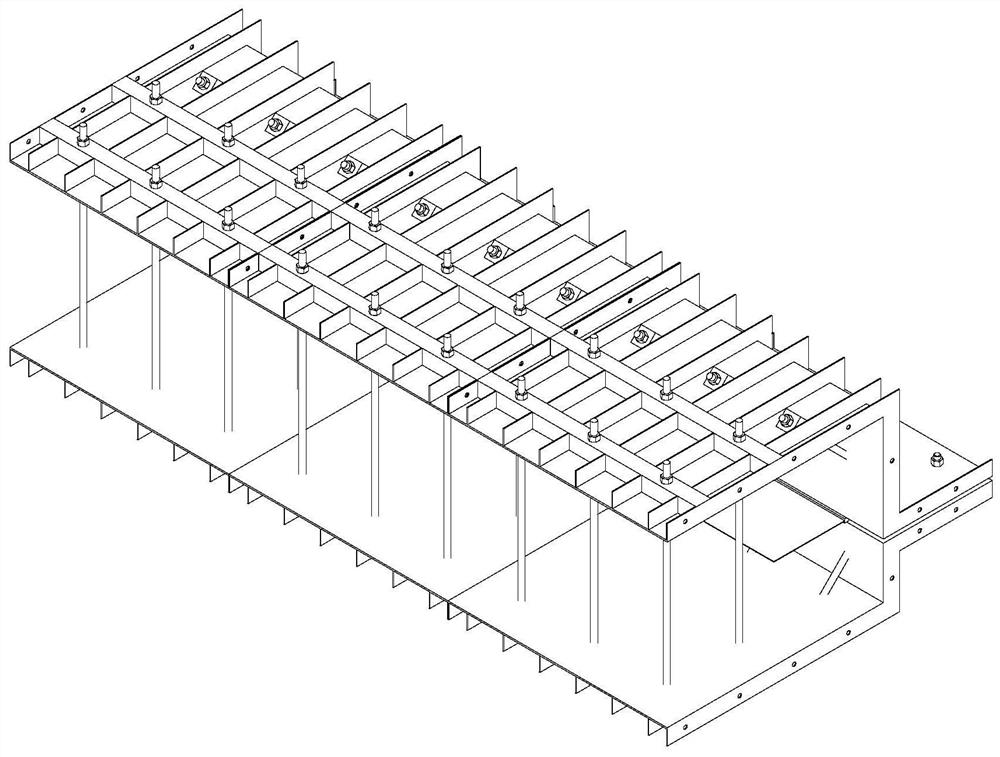

[0026] like figure 1 , 2 , 3, a formwork for the construction joint of the wall of the pipe gallery, including an upper Z-shaped formwork 1, a lower Z-shaped formwork 2, steel mold strips 3, long tie bolts 4, inclined irons 5, cable-stayed Rib sleeve 6, rib plate 7, waterstop 8, connecting flange 9, connecting bolt 10, the upper Z-shaped shaping template 1 and the lower Z-shaped shaping template 2 are relatively arranged, and the upper Z-shaped shaping template 2 is connected by connecting bolt 10 The font-shaped shaping template 1 and the lower Z-shaped shaping template 2 are connected together, and the steel mold strips 3 are respectively welded on the outer sides and corner pressing positions of the upper Z-shaped shaping template 1 and the lower Z-shaped shaping template 2, and the steel mold strips 3 plays the role of positioning and reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com