Load frequency determination method for electric vehicle differential torsional impact fatigue test

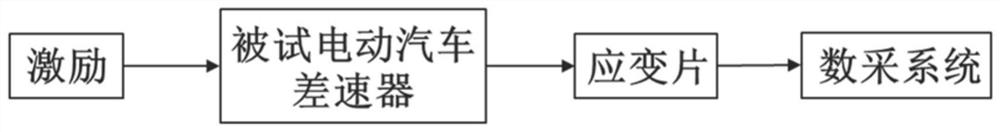

A technology for electric vehicles and impact fatigue, which is applied in vehicle testing, machine/structural component testing, instruments, etc. It can solve the problems of large differences in fatigue damage and lack of objective specifications for the frequency of test load loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better reflect the feasibility and practical application value of the present invention, a complete electric vehicle differential torsional impact fatigue test will be described in detail in this specific embodiment. The steps of the electric vehicle differential torsional impact fatigue test are as follows.

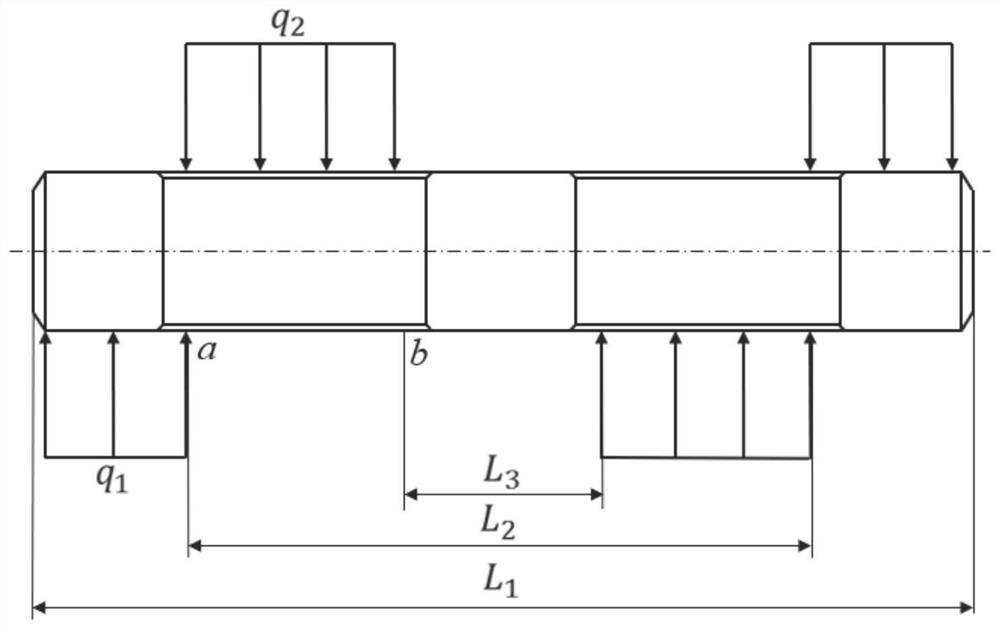

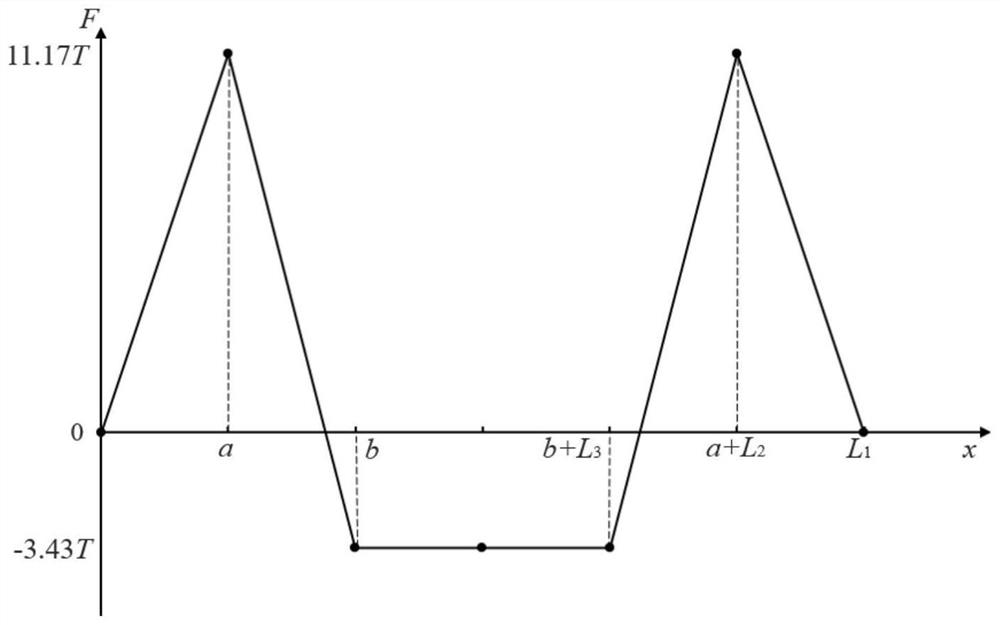

[0046] 1) Determine the test load loading waveform

[0047] Compared with static or quasi-static loads, impact loads have the characteristics of high strength and short time consumption, so that the structure of the test piece shows local deformation and fracture under the action of stress waves.

[0048]According to the current test conditions and technical level, the possibility of completely simulating the actual impact environment in the impact test is low. Existing impact equipment can only output several typical repetitive impact processes with a certain accuracy. As the load output device of the test bench, the torque actuator can output vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com