A test method for bead durability of truck tires

A test method, the technology of trucks, applied in the direction of automobile tire testing, etc., can solve the problems of not reaching the bead durability, shoulder clearance, etc., to reduce the test cost, avoid damage, and improve the success rate of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A test method for bead durability of truck tires:

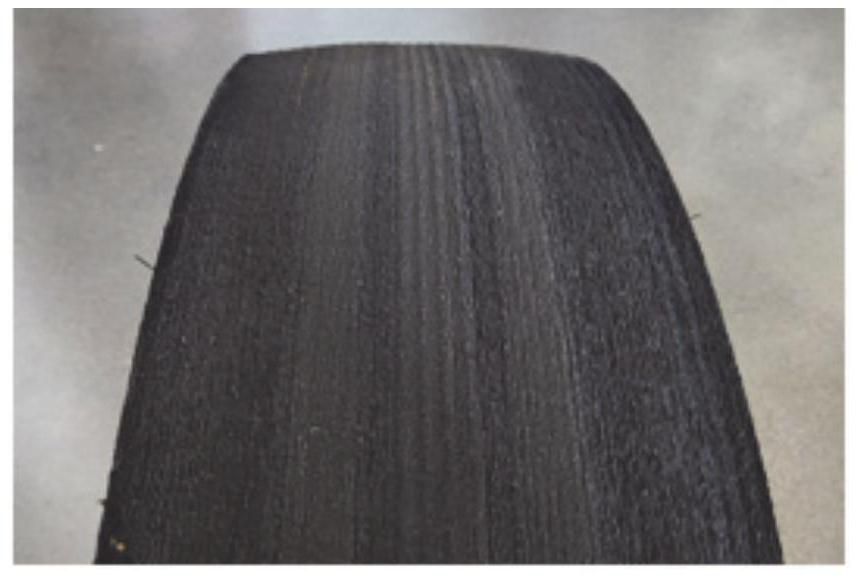

[0030] Grind the tread before tire assembly, and grind the tread to the bottom of the tire pattern groove. The grinding accuracy requires a reserved pattern depth of 0.05mm;

[0031] Install the polished test tire on the rim that meets the requirements, fill it with a test air pressure of 1100kPa, and park the test tire at an ambient temperature of 38°C for 3 hours after inflation;

[0032] Carry out the test: the duration of the first stage is 2h, and the pressure is set to the standard load pressure; the second stage runs until the tire is damaged, and the pressure is set to 200% of the standard load pressure, and the speed remains unchanged at 50km / h during the test; the final bead ruptures The running time of the second stage is 96h 30min.

Embodiment 2

[0034] A test method for bead durability of truck tires:

[0035] Grind the tread before tire assembly, and grind the tread to the bottom of the tire pattern groove. The grinding accuracy requires a reserved pattern depth of 0.01mm;

[0036] Install the polished test tire on the measuring rim that meets the regulations, fill it with a test air pressure of 1100kPa, and park the test tire at an ambient temperature of 39°C for 3.2 hours after inflation;

[0037] Carry out the test: the duration of the first stage is 2h, and the pressure is set to the standard load pressure; the second stage runs until the tire is damaged, and the pressure is set to 200% of the standard load pressure, and the speed remains unchanged at 50km / h during the test; the final bead ruptures The running time of the second stage is 97h 50min.

Embodiment 3

[0039] A test method for bead durability of truck tires:

[0040] Grind the tread before tire assembly, and grind the tread to the bottom of the tire pattern groove. The grinding accuracy requires a reserved pattern depth of 0.02mm;

[0041] Install the polished test tire on the measuring rim that meets the regulations, fill it with a test air pressure of 1100kPa, and park the test tire at an ambient temperature of 40°C for 3.5 hours after inflation;

[0042] Carry out the test: the duration of the first stage is 2h, and the pressure is set to the standard load pressure; the second stage runs until the tire is damaged, and the pressure is set to 200% of the standard load pressure, and the speed remains unchanged at 50km / h during the test; the final bead ruptures The running time of the second stage is 96h 49min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com