One-stop intelligent defect detection system

A defect detection, one-stop technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., can solve the problems of staying in manual naked eye detection and poor versatility of detection tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

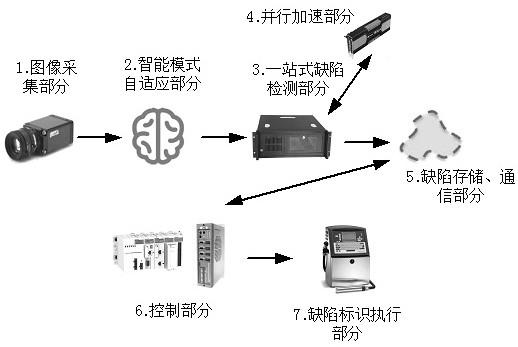

[0073] Such as figure 1 As shown, the one-stop intelligent defect detection system includes:

[0074] The image acquisition part is composed of a camera, a lens, and a photonics subsystem. The image acquisition part is used to collect the original image of the inspected material; it can collect the original image of the inspected material with high quality and high contrast.

[0075] The intelligent mode adaptive part is realized by the detection mode adaptive algorithm. The detection mode adaptive algorithm realizes the closed-loop control by constructing the defect detection result quality evaluation function, and realizes intelligent selection and switching of detection modes for different materials to be detected.

[0076] The one-stop defect detection part is realized by the one-stop defect detection algorithm, which is used to realize all defect types and defect location information covered by the camera field of view; at the same time, the one-stop defect detection alg...

Embodiment 2

[0082] The operation process of the one-stop intelligent defect detection system includes the following steps:

[0083] Step 1. Collect several images of good products;

[0084] Step 2. Collect several images of defective products;

[0085] Step 3. Online deployment of defect detection starts, and the intelligent mode adaptive part intelligently matches the detection mode through the good product image and the defective product image;

[0086] Step 4. One-stop normal defect detection, parallel computing acceleration;

[0087] Step 5, storing defect detection results and sending detection information to the control part;

[0088] Step 6, the control part receives the detection information, and sends a related control signal;

[0089] Step 7, the defect identification execution part receives the control signal from the control part, and makes corresponding execution actions.

[0090] Among them, the execution part of defect identification can specifically be a cylinder with ...

Embodiment 3

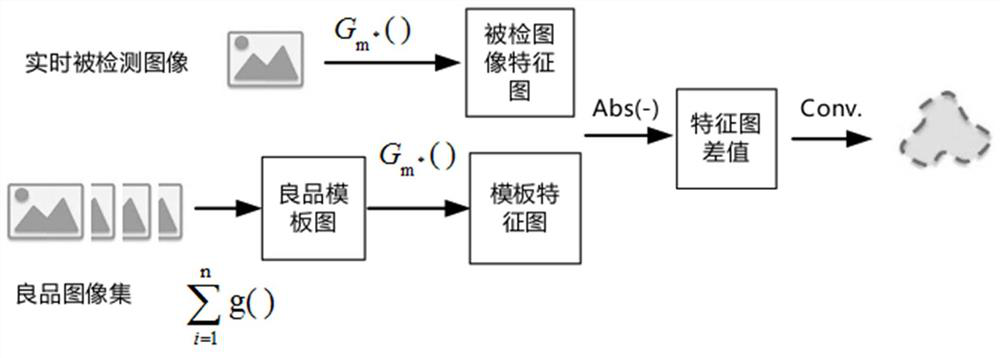

[0092] The realization of the one-stop defect detection algorithm:

[0093] The one-stop defect detection algorithm can select different detection modes to adapt to inspected materials of different materials. The detection mode adaptive algorithm can independently select the optimal detection mode. The parallel acceleration algorithm module provides a powerful one-stop defect detection algorithm. computational support.

[0094] Since the image acquisition part is determined, the acquired image resolutions are consistent, and the image resolution (height, width) involved in the one-stop defect detection algorithm must be consistent, otherwise the normal defect detection cannot be performed; if the actual application, the acquisition If the resolutions of the images are not consistent, then the advanced resolution will be converted uniformly and then the defect detection will be carried out. The method is as follows:

[0095] ,

[0096] ,

[0097] in, is the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com