Waste machine tool key part residual life prediction and evaluation method

A technology of life prediction and waste, which is applied in prediction, computer-aided design, instruments, etc., can solve the problems of inaccurate calculation of remaining life and insufficient precision of mathematical models, etc., and achieve the effect of accurate prediction and evaluation results, accurate prediction, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

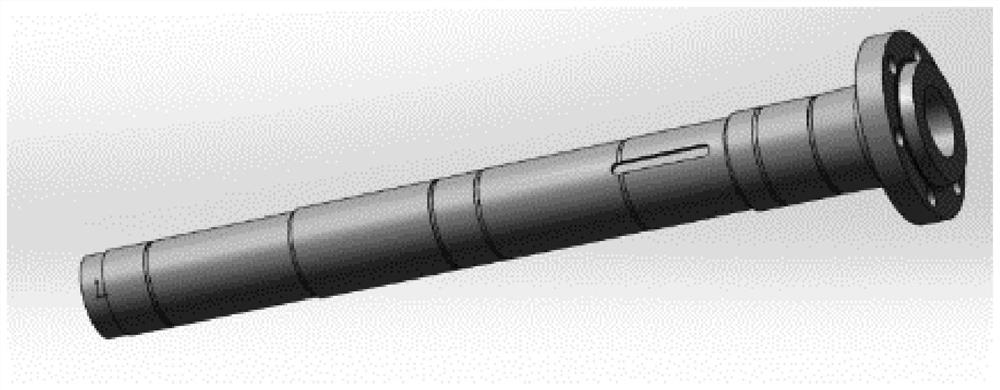

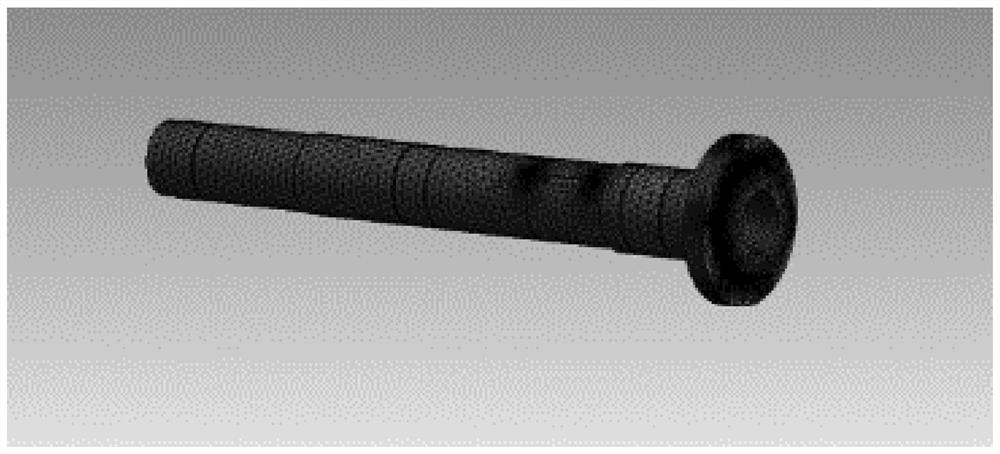

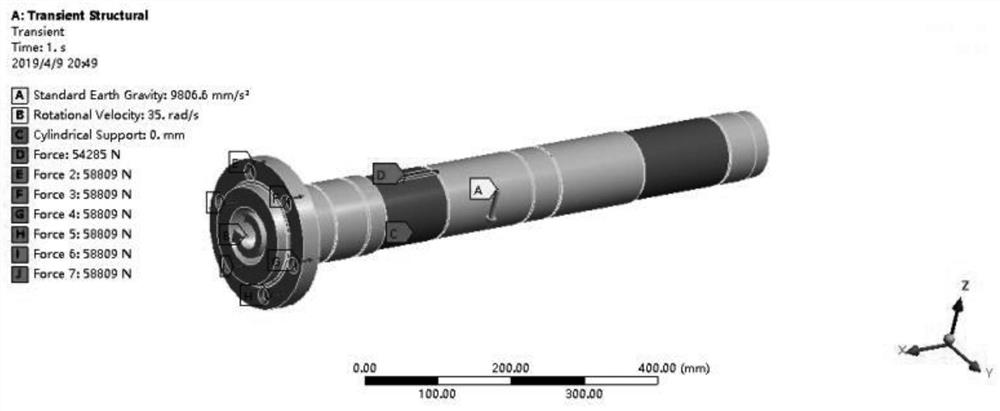

[0052] The present invention takes the main shaft of machine tool CAK5085 as the research object.

[0053] (1) Construct the residual life prediction model of the waste spindle

[0054] ①The nonlinear continuous fatigue damage model of the waste spindle:

[0055] Taking the nonlinear continuous fatigue cumulative damage model proposed by CHABOCHE as the core, the discontinuous fatigue damage model of the waste spindle is constructed:

[0056] The form of the nonlinear continuous fatigue cumulative damage model proposed by CHABOCHE is as follows:

[0057] dD=f(σ max ,σ m ,D)dN (1.1)

[0058] where D, N, σ max , σ m are the damage variable, the number of load actions, the maximum stress and the mean stress, respectively.

[0059] CHABOCHE suggested using formula (1.2) to express the relationship between damage and the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com