Heat exchanger and method for manufacturing such heat exchanger

A heat exchanger and channel technology, applied in the field of heat exchangers, can solve problems such as increased pressure head loss, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

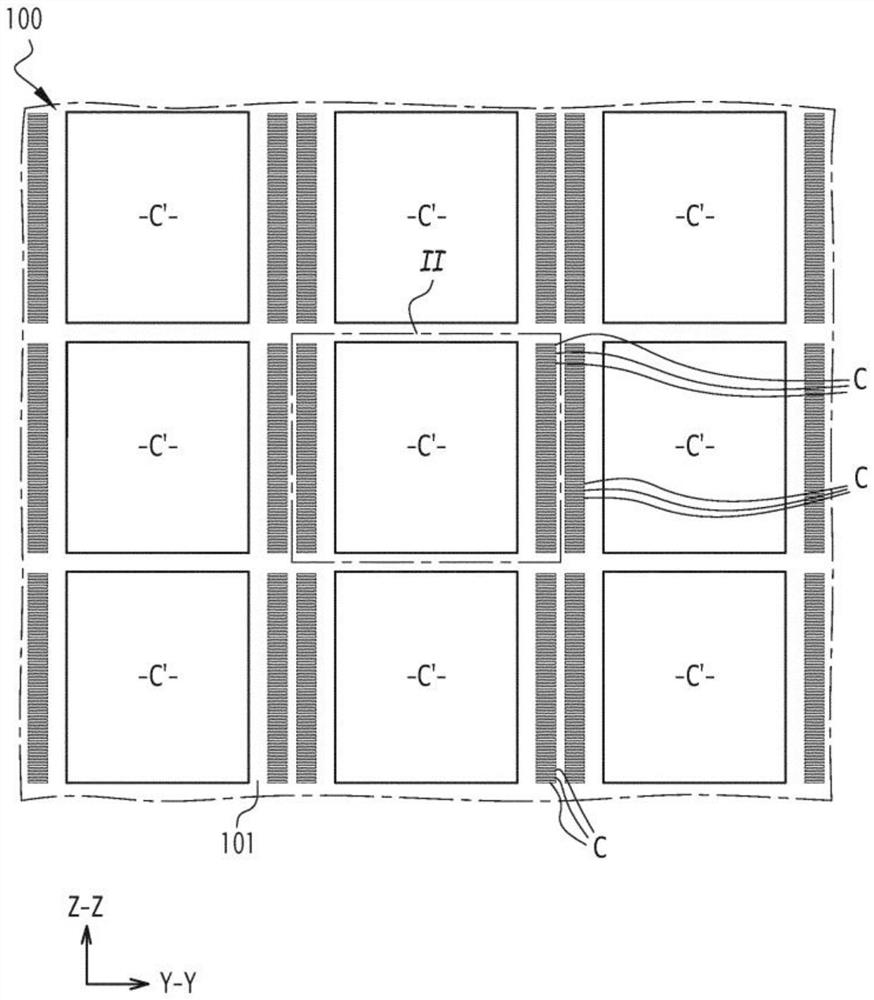

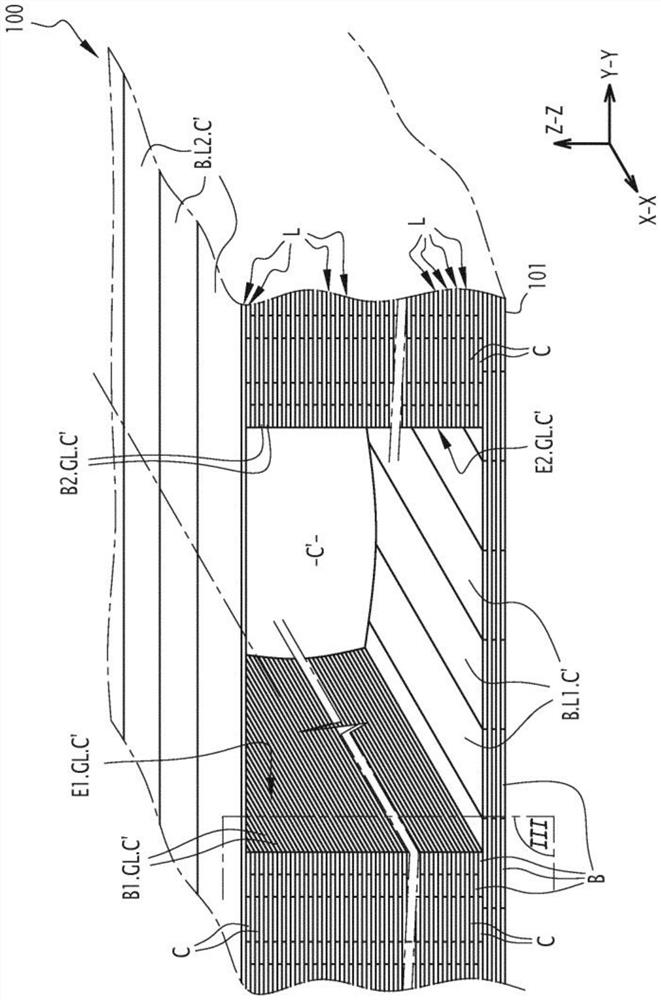

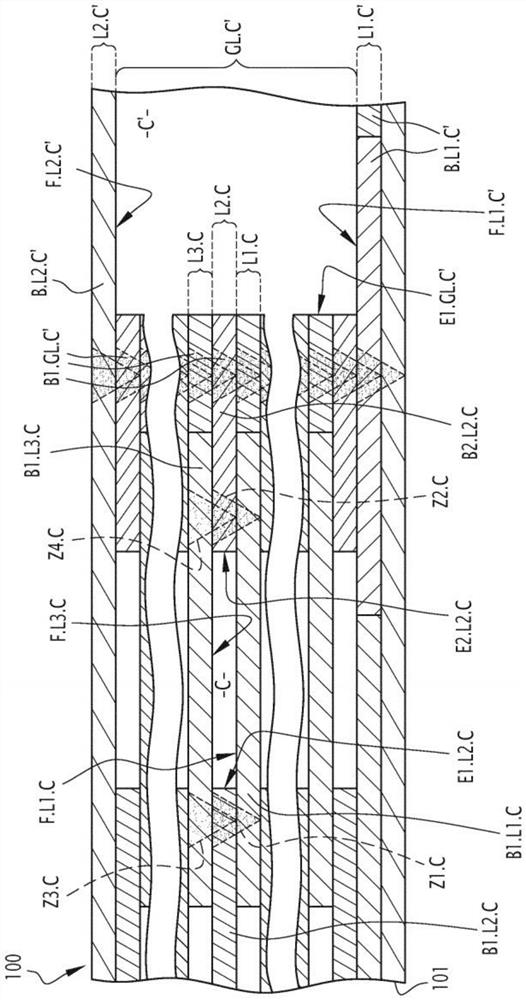

[0036] Figure 1 to Figure 3 A heat exchanger 100 is shown. The exchanger 100 is a recuperator which allows the transfer of thermal energy between a first fluid and a second fluid passing through the body 101 through the body 101 of the exchanger without any mixing between the first fluid and the second fluid .

[0037] As outlined below, the body 101 is made of metal and has a three-dimensional shape that will be described with reference to an orthogonal coordinate system having axes labeled X-X, Y-Y and Z-Z, respectively.

[0038] The exchanger 100 comprises both channels C for the first fluid circulation and channels C' for the second fluid circulation. As described in detail below, the channels C and C', delimited by the main body 101 of the exchanger, extend longitudinally parallel to each other along the axis XX, each of these channels C and C' facing each other along the axis XX with respect to the respective channels of the channel. terminals are connected to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com