Truss type topping robot and working method thereof

A robot and truss-type technology, applied in horticultural methods, botanical equipment and methods, cutting tools, etc., can solve the problems of crop secondary growth, low efficiency, missed cropping, etc., and achieve the effect of reducing damage and preventing missed cropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

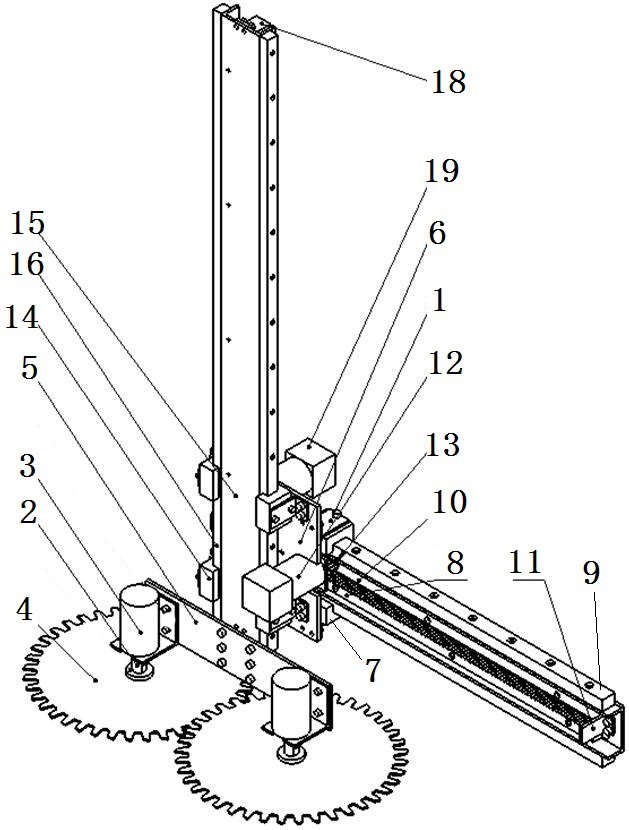

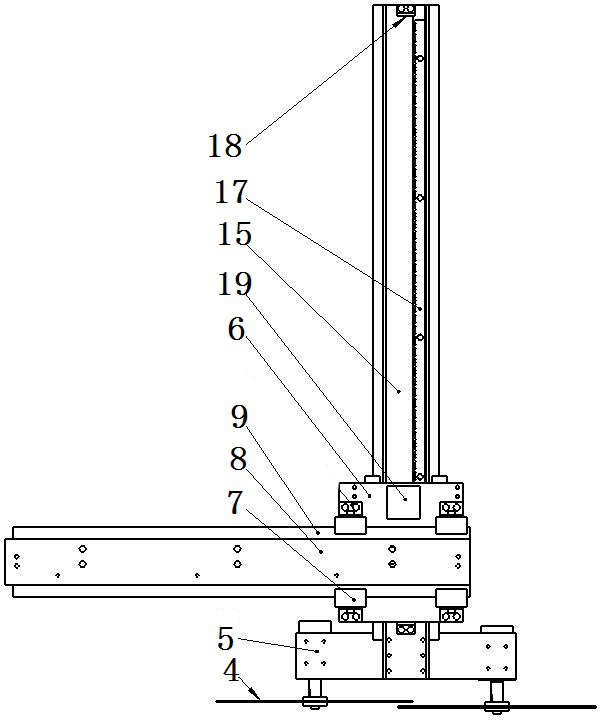

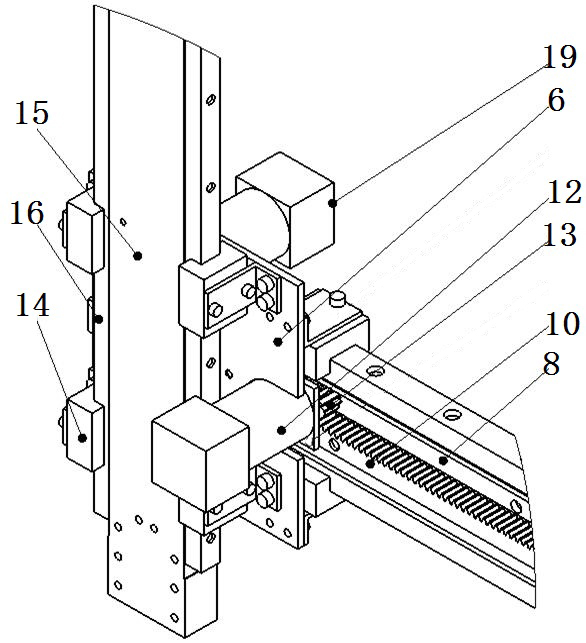

[0021] like Figure 1~6 As shown, a truss-type topping robot includes a topping mechanism 2 driven by an electric mechanism 1 to move horizontally and vertically. The topping mechanism includes a sawtooth blade 4 driven to rotate by a topping motor 3 .

[0022] In the embodiment of the present invention, the topping mechanism includes a cutter mounting plate 5. The serrated blade has two pieces and is installed on the left and right ends of the cutter mounting plate. The two serrated blades are arranged alternately up and down. The spacing and the horizontal direction coincide for a certain distance.

[0023] In the embodiment of the present invention, the two sawtooth blades are separately driven to rotate by two topping motors.

[0024] In the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com