Automatic press-fit forming equipment for bread

A molding equipment and automatic technology, applied in the direction of dough molding machinery or equipment, application, baking, etc., can solve the problems of increasing staff burden, reducing work efficiency, complex structure, etc., to save energy consumption, improve work efficiency, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

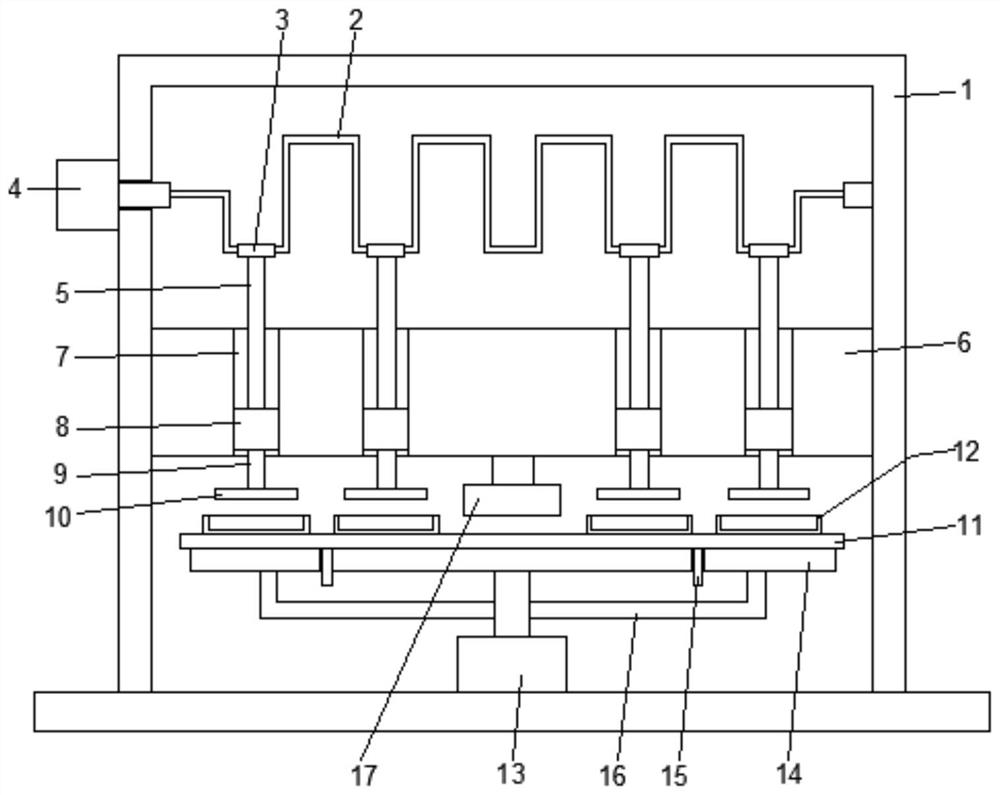

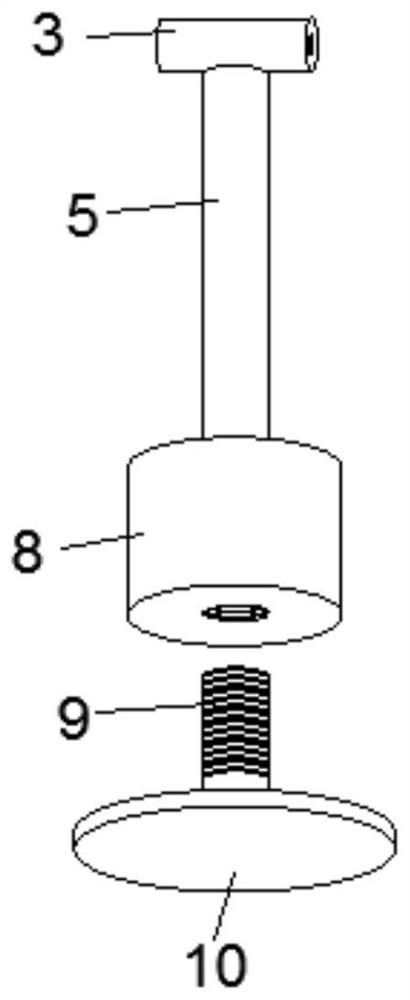

[0032] An automatic pressing and forming equipment for bread, including a frame 1, a control shaft 2, an auxiliary plate 3 and a supporting plate 11, the control shaft 2 is in the shape of a broken line, the left end of the control shaft 2 is connected to a No. 1 motor 4, and the right end passes through a bearing The seat is rotatably connected to the frame 1, and four rotating cylinders 3 are movably socketed on the control shaft 2, and the outer wall of the rotating cylinder 3 is vertically connected with a piston rod 5; the left and right sides of the auxiliary plate 3 are fixedly installed on the frame 1 , and the auxiliary plate 3 is located below the control shaft 2, wherein the auxiliary plate 3 is provided with a cylindrical through groove 7, and there are four through grooves 7, which are located directly below the drum 3 one by one. Pistons 8 are arranged in the through grooves 7, the upper side of the pistons 8 is connected with the bottom end of the piston rod 5, t...

Embodiment 2

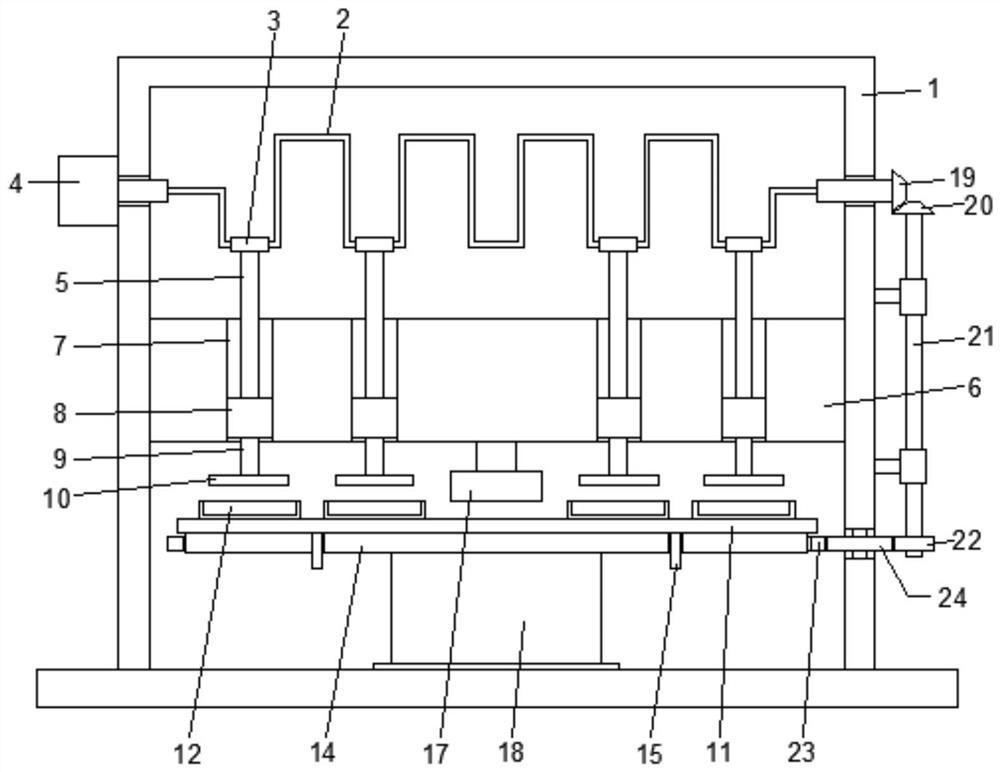

[0036] What is different from Embodiment 1 is that the rotating mechanism includes a rotating rod 18 and a worktable 14, the top of the rotating rod 18 is connected below the working table 14, and the bottom end is rotated and arranged on the frame 1; the working table 14 is cylindrical, and the working The platform 14 is provided with a positioning hole 1401 , and the bottom surface of the supporting plate 11 is provided with a positioning rod 15 which can be inserted into the positioning hole 1401 correspondingly.

[0037] Also be provided with control mechanism on frame 1 in addition, control mechanism comprises first bevel gear 19, rotating shaft 21, second bevel gear 20, master gear 22, ring rack 23 and slave gear 24, first bevel gear 19 is connected on The right end of the control shaft 2, the rotating shaft 21 is connected on the frame 1 by a bearing, the rotating shaft 21 is vertically arranged, the second bevel gear 20 is connected on the top of the rotating shaft 21, ...

Embodiment 3

[0040] A protective plate 17 is connected to the center of the bottom surface of the auxiliary plate 6. The protective plate 17 is located above the supporting plate 11. A protective cover 1701 is provided on the lower side of the protective plate 17, wherein the protective plate 17 is fork-shaped. When one of the mold sets 12 is located directly below the platen 10, the other two mold sets 12 will be located directly below the protective plate 17. At this time, the protective cover 1701 on the protective plate 17 can cover the corresponding lower mold box 1201, preventing bread polluted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com