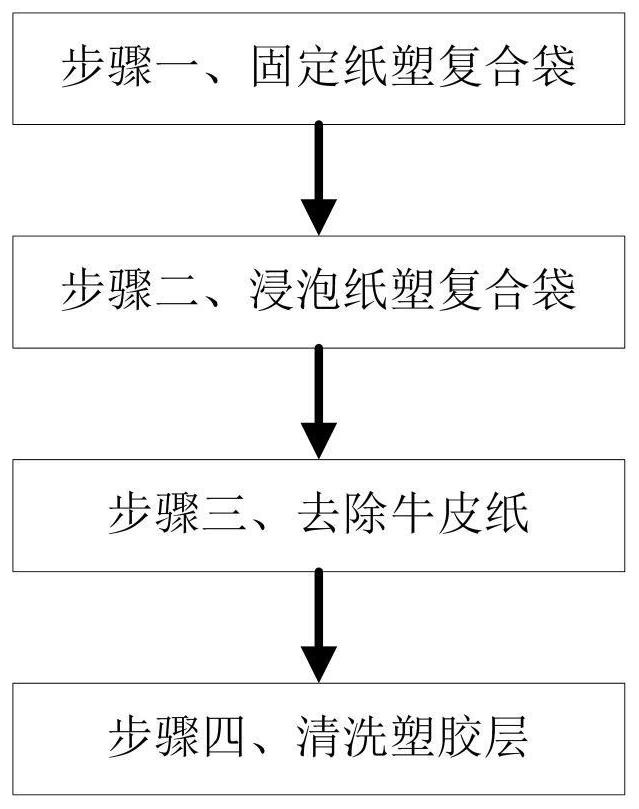

Renewable environment-friendly paper-plastic compound bag recycling method

A paper-plastic composite bag and recycling technology, applied in the field of paper-plastic composite bags, can solve the problems of scraping kraft paper easily scratching the surface of the plastic layer, scraping the kraft paper cleanly, and adverse effects of recycling the plastic layer, etc., so as to avoid scratches. The effect of damaging the surface of the plastic layer and improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

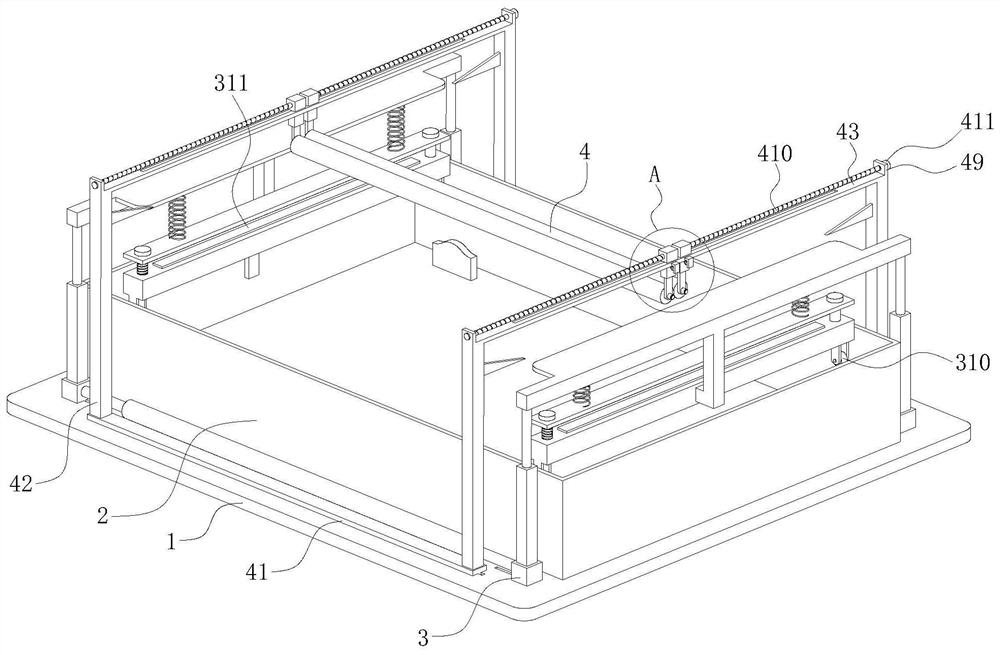

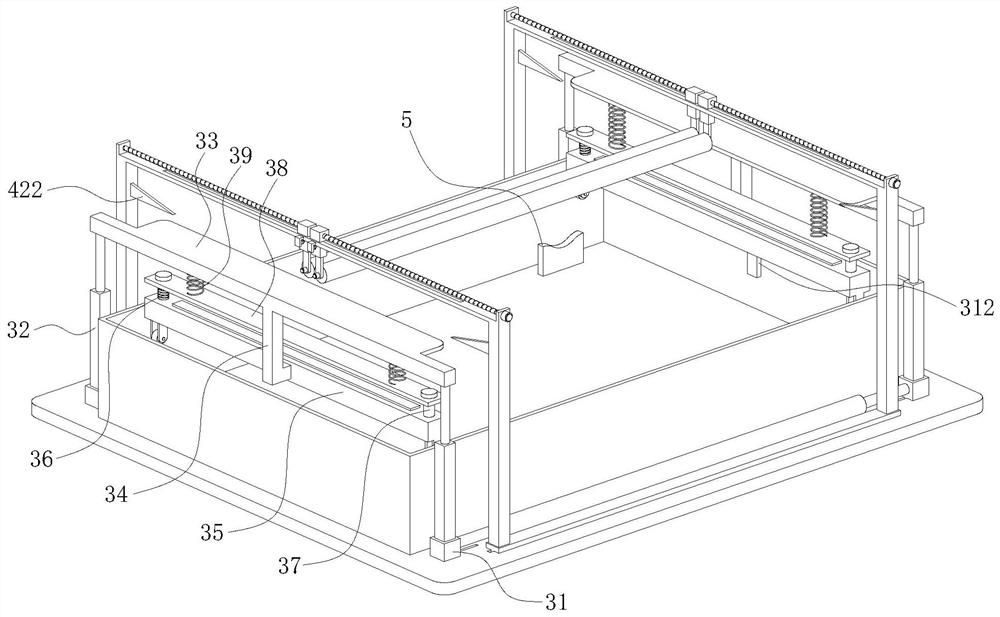

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0034] Such as Figure 2 to Figure 6 As shown, this embodiment provides a recyclable and environmentally friendly paper-plastic composite bag recycling machine, including a horizontal bottom plate 1, and a water tank 2 with a rectangular cross section is fixedly installed on the upper surface of the bottom plate 1, and the top surface of the water tank 2 forms an opening. . Two clamping mechanisms 3 are mounted symmetrically on the upper surface of the bottom plate 1 left and right. A cleaning mechanism 4 is installed on the upper surface of the bottom plate 1 .

[0035] The clamping mechanism 3 includes an electric slider 31 , a cylinder 32 , a top plate 33 , a bracket 34 , a pressure bar 35 , a lead screw 36 , a guide rod 37 , a pressure bar 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com