Compact paper distribution system

A compact and paper-matching technology, which is applied in the direction of external support, transportation packaging, and object supply, can solve the problems of large spacing, increased volume of ceramic tile packaging equipment, and insufficient space for installation, etc., to achieve high position accuracy, Small footprint and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

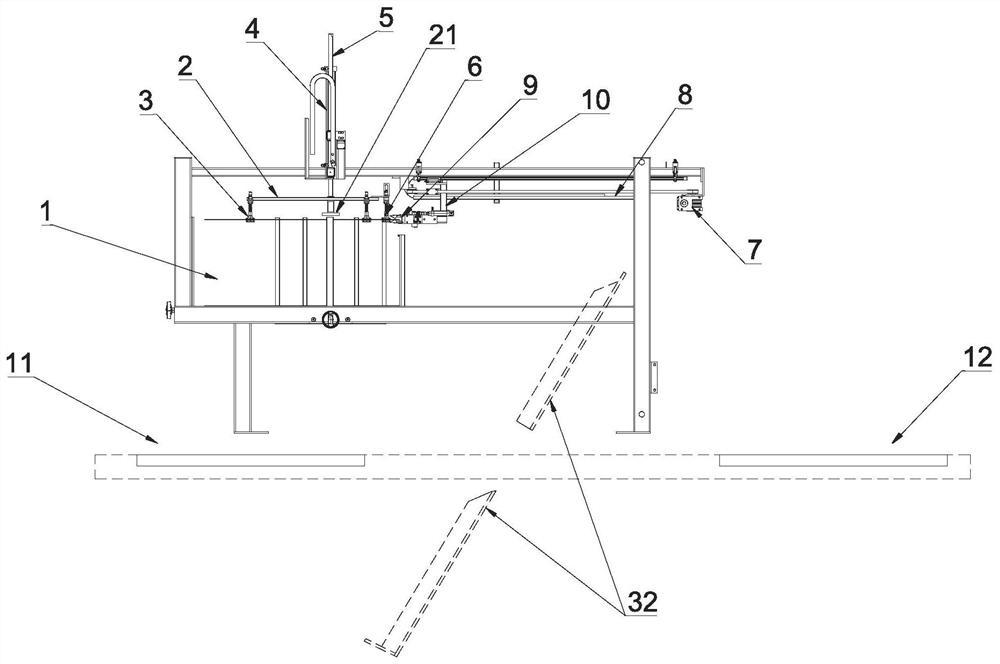

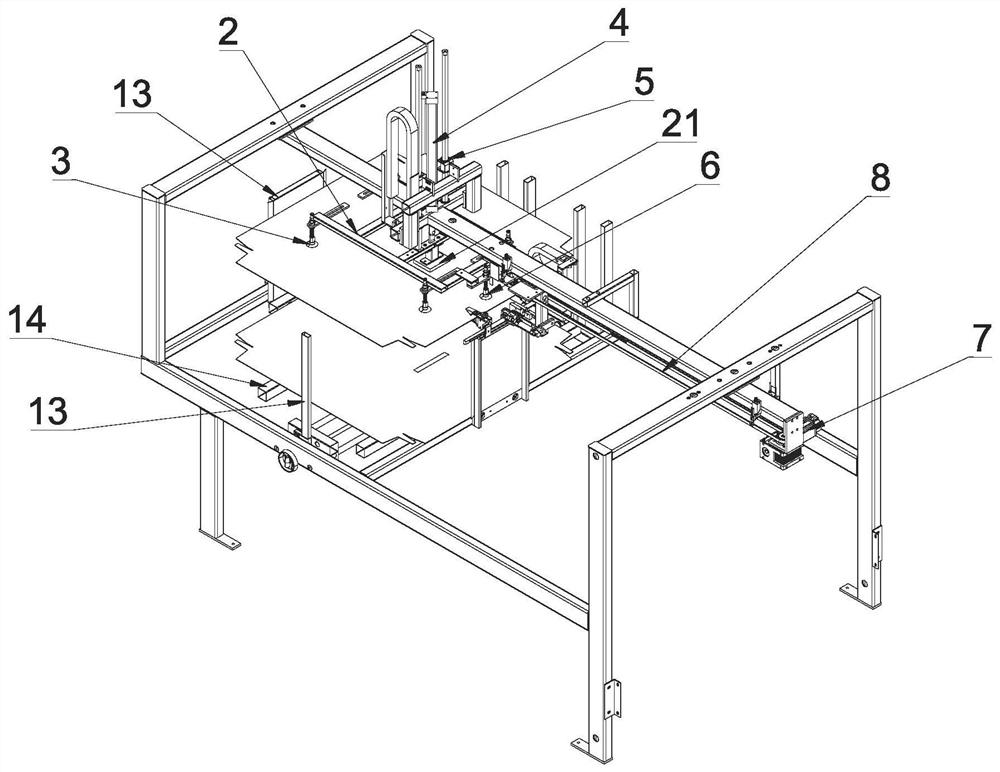

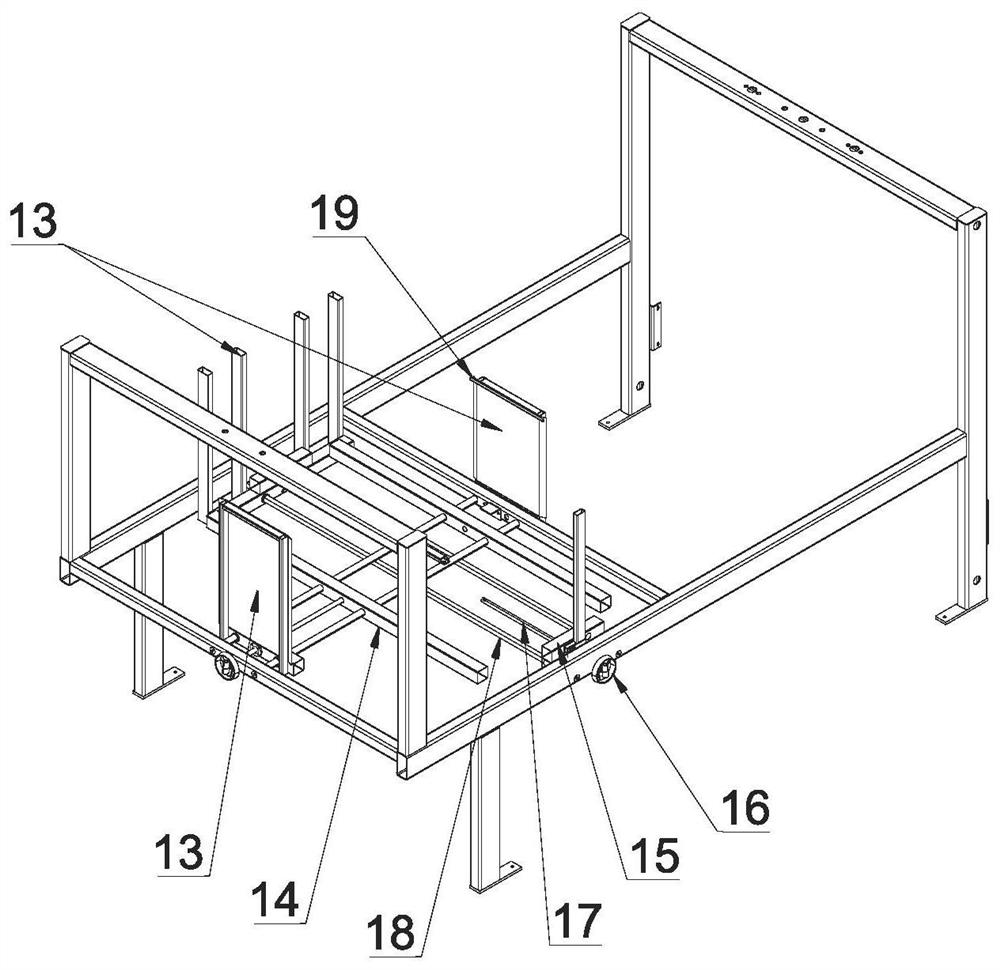

[0026] see Figure 1-Figure 5 , the compact paper dispensing system of this embodiment includes a paper bin 1, a paper feeding mechanism and a slideway 32, the paper bin 1 is horizontally arranged above the feeding belt, and the paper feeding mechanism is arranged on the paper bin 1, along the moving direction of the tiles, the slideway 32 is arranged in front of the paper bin 1; wherein, the cardboards to be packaged are horizontally stacked and placed in the paper bin 1; the slideway 32 is arranged obliquely, And when the cardboard slides to the temporary storage position of the slideway 32, the cardboard is located below the feeding belt and a side packaging margin of the cardboard stretches out on the feeding belt, and is positioned at the incoming material station 11 of the ceramic tile. and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com