Pre-restrained bamboo pipe combined component, joint structure and construction method

A technology of combining components and node structures, which is applied in the direction of structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems of deformation of the entire structure, poor reliability of connecting nodes, poor structural safety, etc., to improve the bearing capacity. The effect of strength and ductility, increased safety redundancy, and improved compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

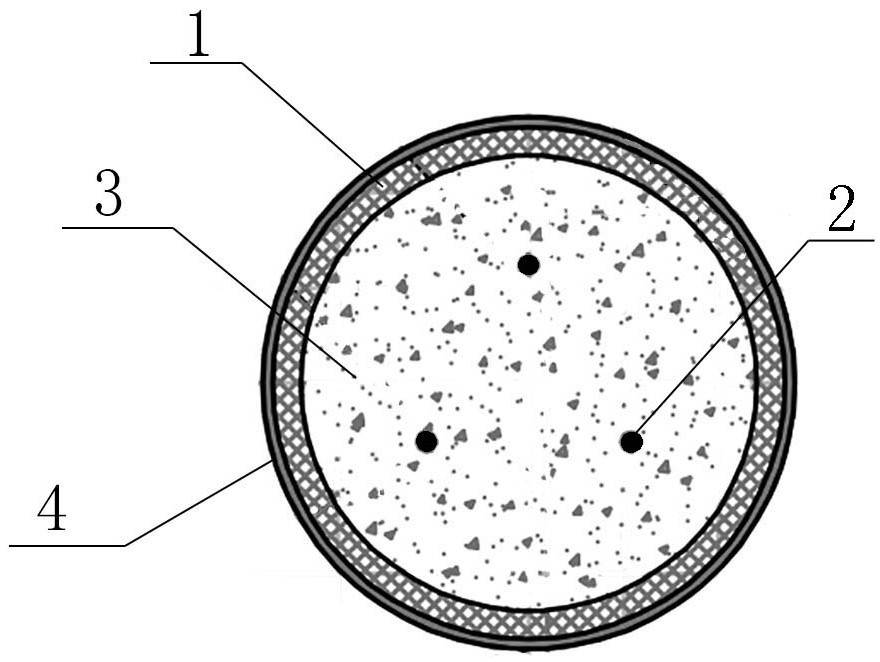

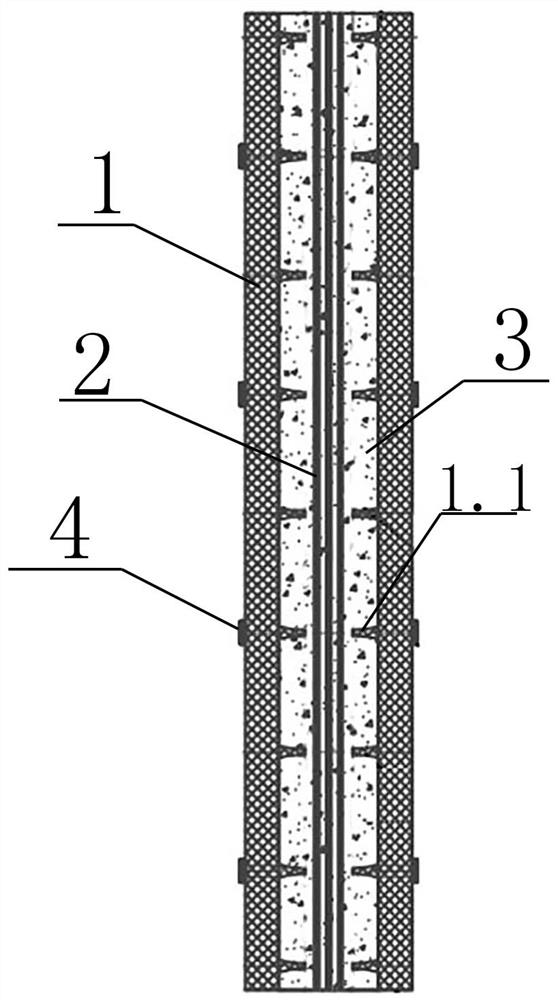

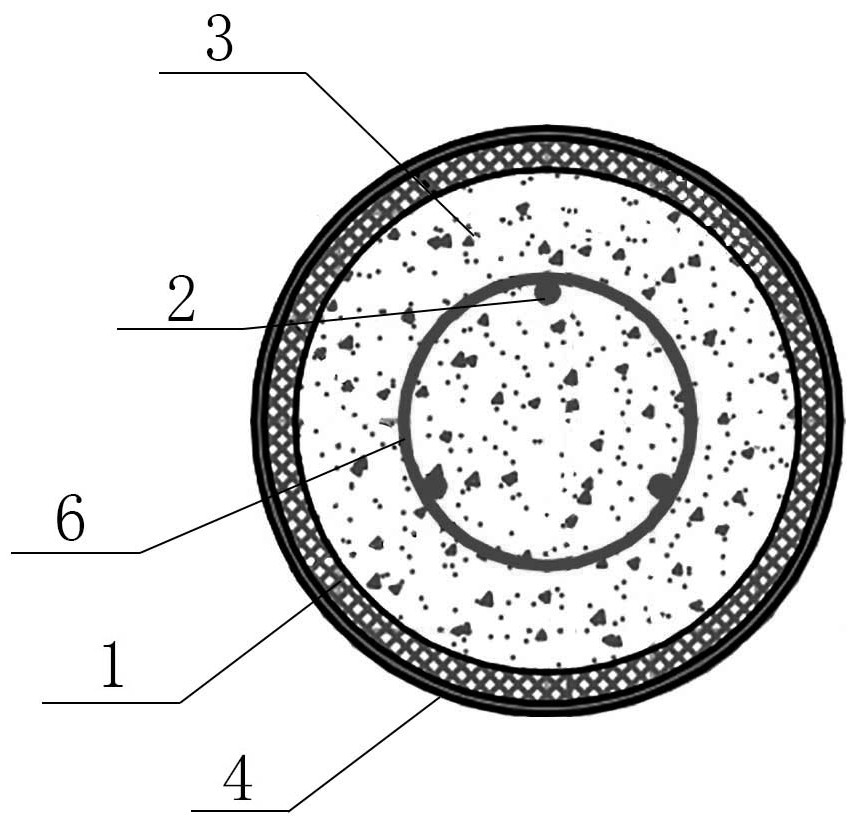

[0037] Such as Figure 1-10 As shown, this pre-constrained bamboo tube composite member includes a bamboo tube 1; it also includes a vertical rib 2, a filling material 3 and a circumferential restraint 4; There are holes 5; there is one set of vertical ribs 2, which are inserted in the bamboo tube 1 at intervals; the filling material 3 fills the internal cavity of the bamboo tube 1; there are multiple sets of ring restraints 4, which are vertically inserted into the bamboo tube 1; Intervals are arranged on the outside of the bamboo tube 1.

[0038] In this embodiment, the diameter of the bamboo tube 1 is 30 mm to 1000 mm; stirrups 6 are arranged outside a group of vertical ribs 2; the stirrups 6 are arranged vertically to form a reinforcement cage.

[0039] In this embodiment, the filling material 3 is concrete or cement mortar or grouting material or gypsum or lime; the vertical bars 2 are steel bars or FRP bars or bamboo bars; the hoop constraints 4 It is a metal ring plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com