Liquid pump and electric appliance

A liquid pump and pump core technology, which is applied to liquid variable volume machinery, liquid fuel engines, pumps, etc., can solve problems such as liquid pump failure, and achieve the effect of prolonging life and increasing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

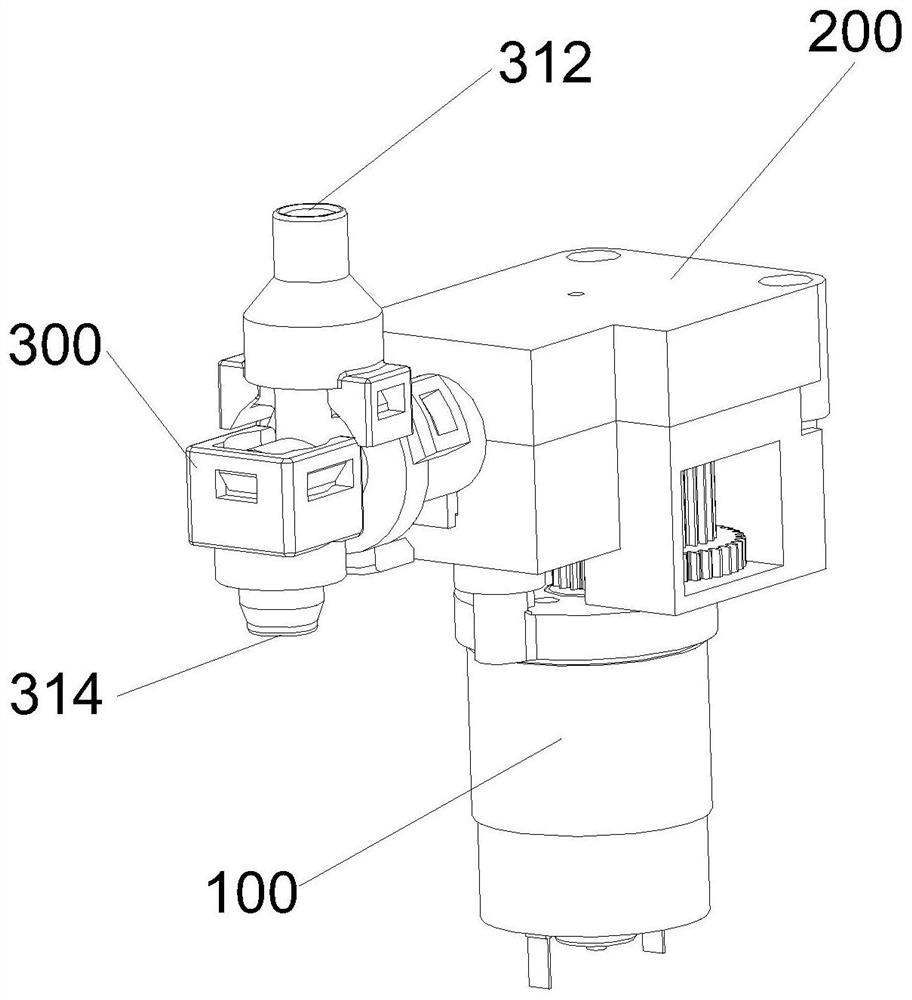

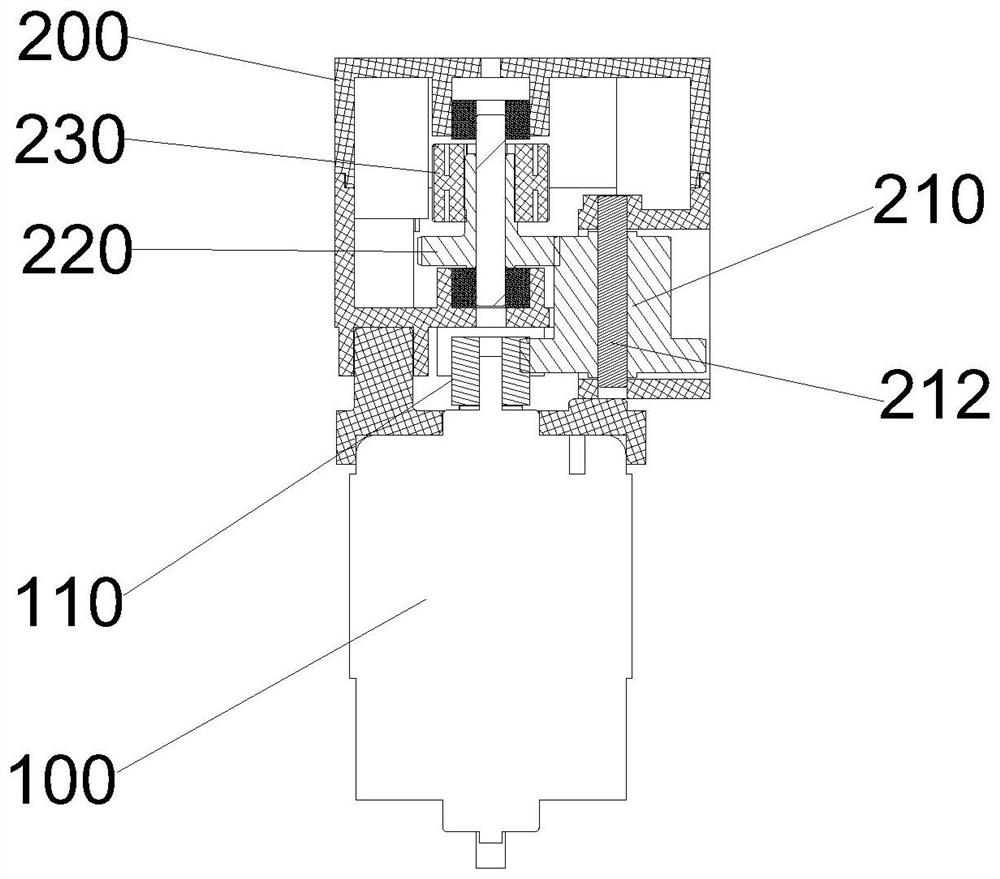

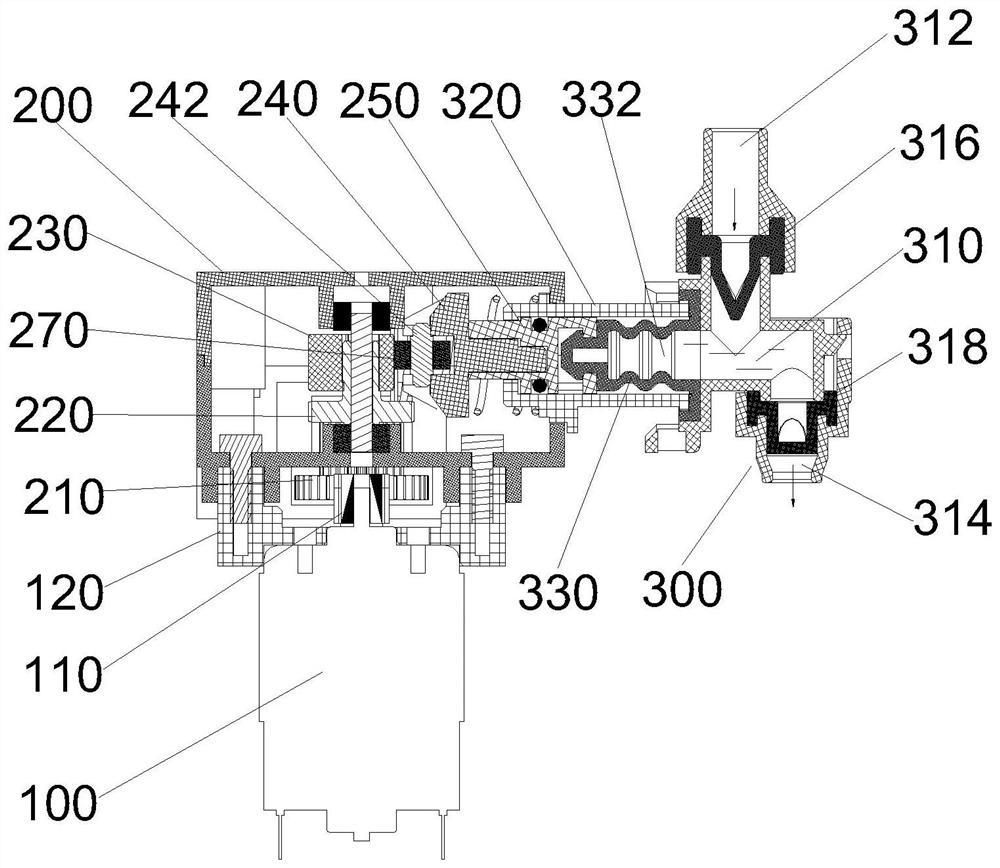

[0024] Example: such as Figure 1-5 As shown, the present invention discloses a first embodiment of a liquid pump, which includes a motor 100 , a transmission structure 200 connected to the output of the motor 100 , and a pump body 300 matched with the output of the transmission structure 200 .

[0025] The motor 100 includes an output gear 110 located on the output shaft of the motor, and the motor 100 is preferably a DC brushed or brushless motor. The direction of the output shaft of the motor is perpendicular to the movement direction of the pump core 330 . The motor 100 is provided with a motor fixing frame 120 matched with the transmission structure 200 .

[0026] The transmission structure 200 includes a gear box 204 fixedly connected with the motor fixing frame 120, a gear box cover 206 tightly fitted with the gear box 204, a primary gear 210 accommodated by the gear box 204 and meshed with the output gear 110, The secondary gear 220 housed in 204 and meshed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com