A heat exchanger core group used in acid-base corrosion environment and its coating method

An acid-base corrosion and heat exchanger technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of uniform coating and difficult construction of various components of the core group, and achieve excellent mechanical properties and good resistance. , the effect of excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

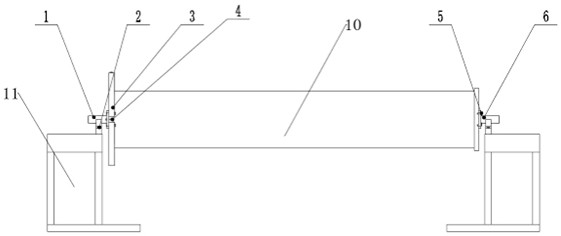

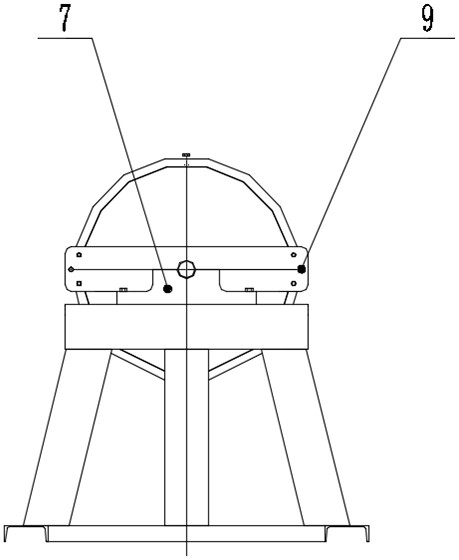

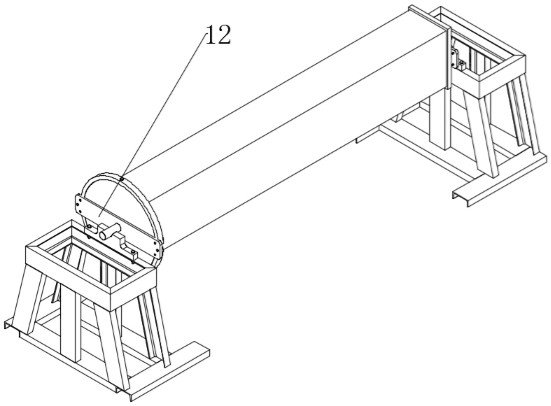

[0037] see Figure 1-3 , this embodiment provides a heat exchanger core group for use in an acid-base corrosion environment, including:

[0038] A bracket 11, the bracket 11 is provided with two;

[0039] A core group body 10, the two ends of the core group body 10 are respectively connected to the bracket 11;

[0040] A round tube plate splint 3, the round tube plate splint 3 is arranged at one end of the core pack body 10;

[0041] A round tube plate flange shaft 1 , one end of the round tube plate flange shaft 1 is connected to the core pack body 10 , and the other end of the round tube plate flange shaft 1 is rotatably connected to the bracket 11 .

[0042] The heat exchanger core set used in the acid-base corrosion environment provided in this embodiment further includes a second bolt 4, and the second bolt 4 passes through the round tube plate splint 3 and the round tube plate flange shaft 1, The round tube plate splint 3 is connected with the round tube plate flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com