Intelligent goods taking and automatic goods checking system and control method thereof

A control method and automatic inspection technology, applied to instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Shipping accuracy and other issues, to achieve the effect of reducing operation and maintenance costs, reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with accompanying drawing.

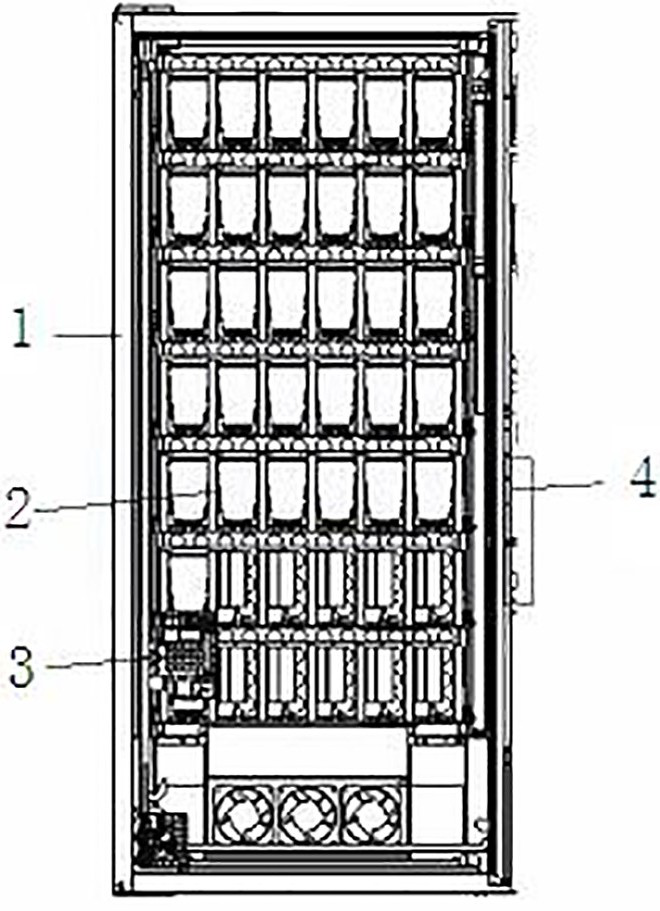

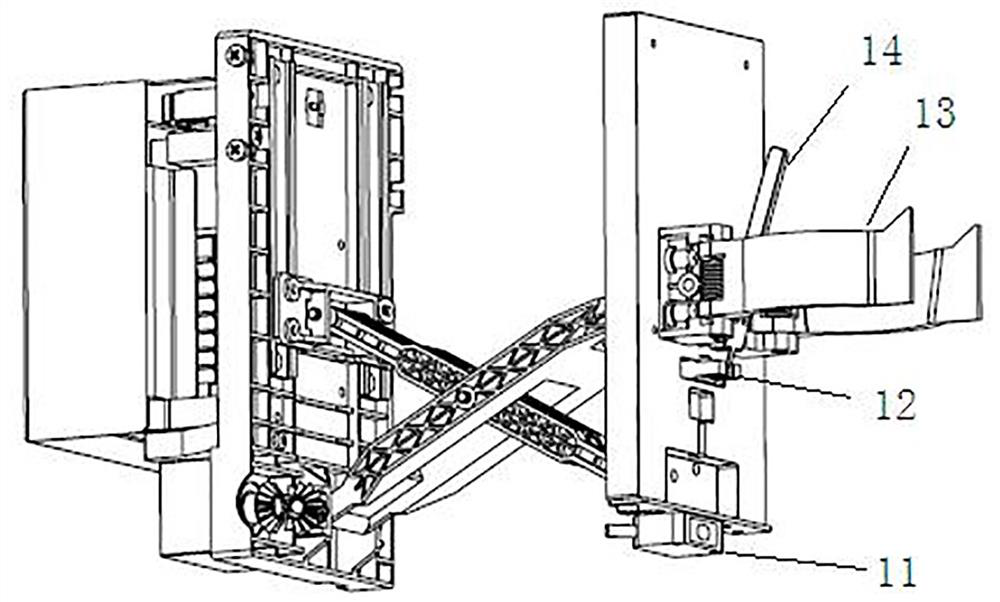

[0073] Such as figure 1 , 3 As shown, the intelligent picking and automatic inspection system includes a container 1, a single-layer shelf 2 placed in the cavity of the container 1 from top to bottom, a delivery port 4 arranged on the side of the container 1, and a shelf installed on the opposite side of the container 1. The picking module 3, the positioning displacement module installed on the back of the picking module 3, the object detection module and the in-position detection module installed in front of the picking module 3.

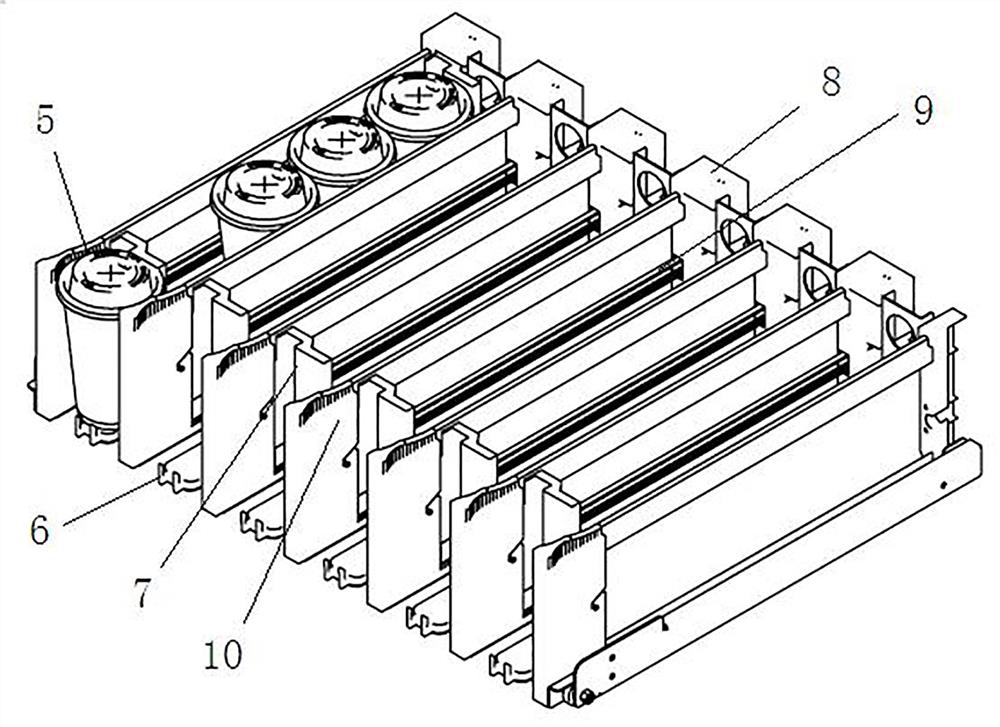

[0074] Such as figure 2 As shown, the single-layer shelf 2 is mainly composed of a bottom plate and vertical partitions installed on it at equal intervals, two adjacent vertical partitions form a cargo lane, and the cargo lane is used to place cups 1; each cargo lane The cargo lane motor 4 is installed at the rear of the cargo lane, the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com