Preparation method of display substrate, display substrate and display device

A technology for display substrates and display devices, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

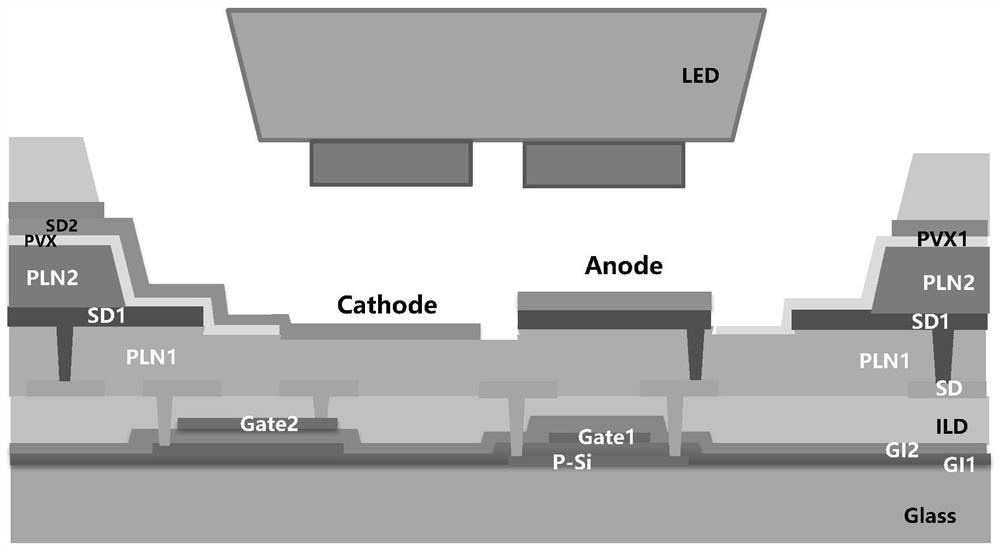

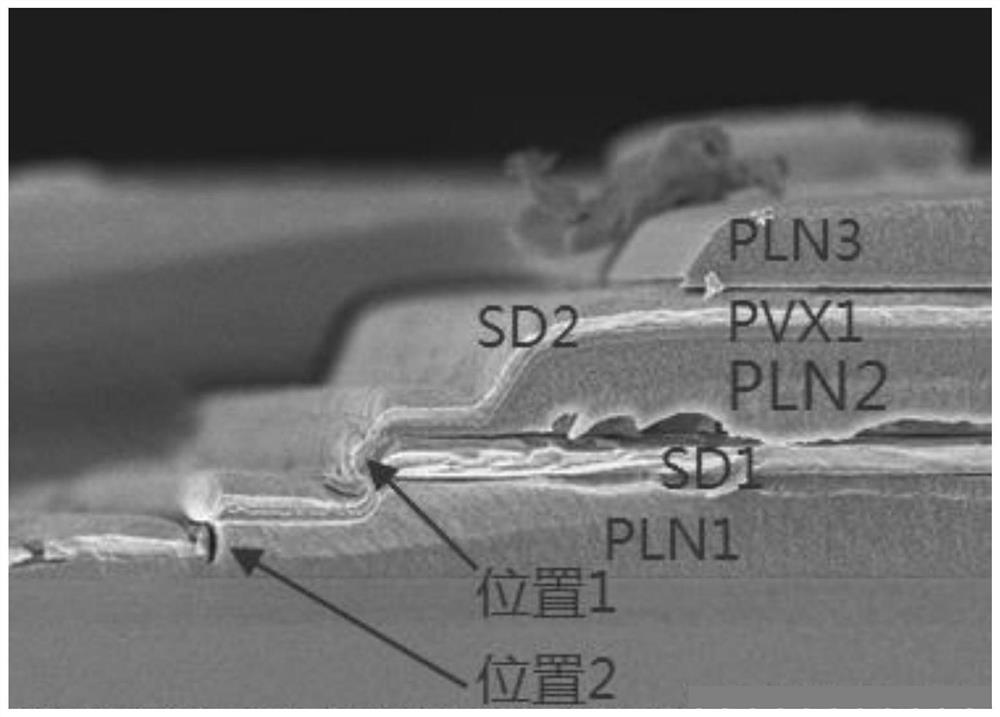

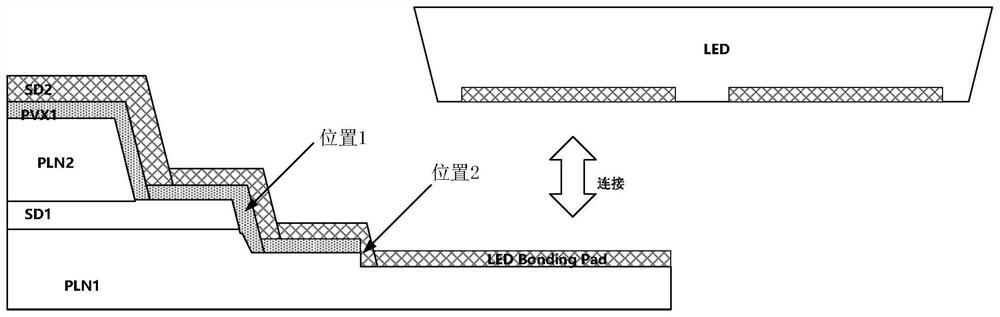

[0039] refer to figure 1 A schematic cross-sectional structure diagram of a display substrate in the related art is shown. In order to achieve the purpose of reducing IRDrop, a device structure of three SD metal layers and two flat layers (Resin) is adopted. Among them, SD1 carries the working voltage VDD signal of the LED device, and SD2 carries the common ground voltage VSS signal. The VDD signal is modulated by the pixel circuit to obtain the ideal anode drive voltage, which is transmitted to the anode Pad, and the VSS signal is transmitted to the cathode Pad. The two ends of the LED are respectively connected to the anode Pad and the cathode Pad, and the pressure difference between the anode Pad and the cathode Pad drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com