Adhesive drying equipment for shoemaking industry

A technology for drying equipment and adhesives, which is applied in the direction of shoemaking machinery, footwear, and adhesive shoe parts, etc. It can solve problems such as difficult control, influence of adhesive drying, and unsatisfactory drying effect, etc., to achieve Convenient operation, guaranteed stability, and high drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

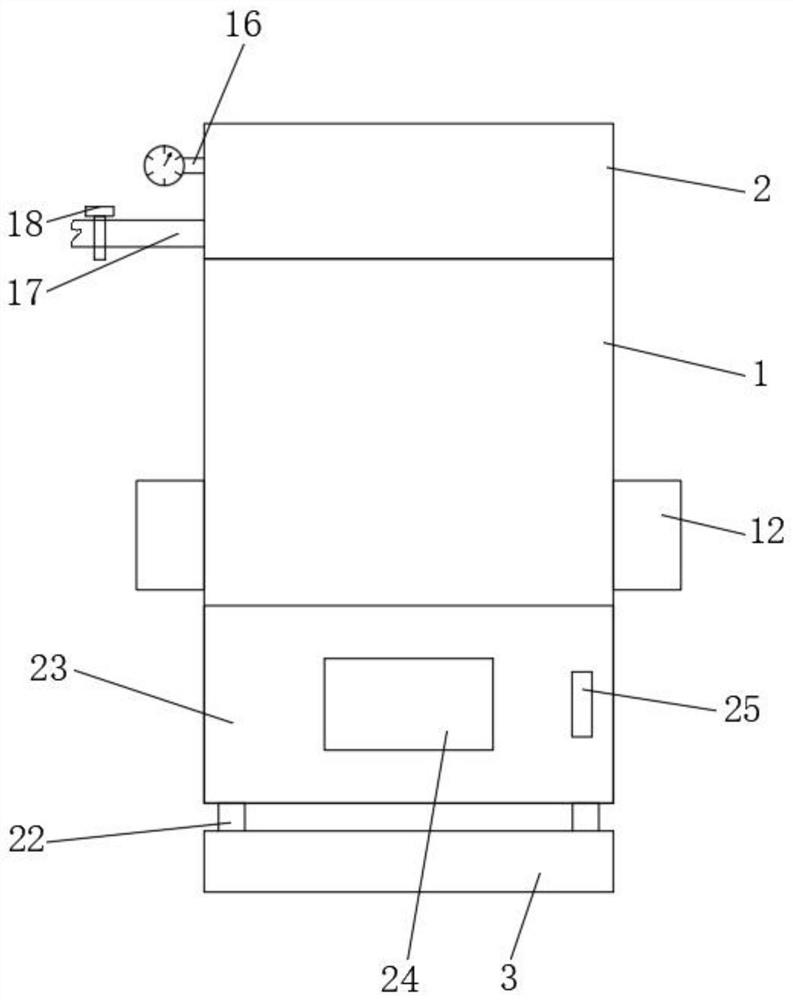

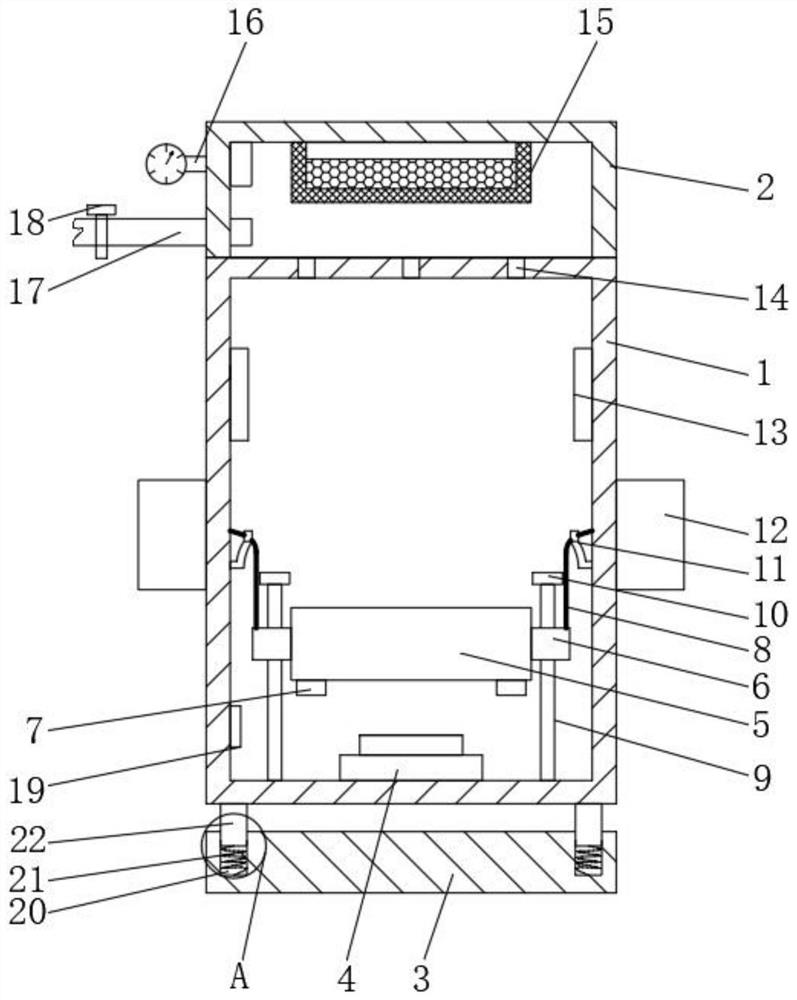

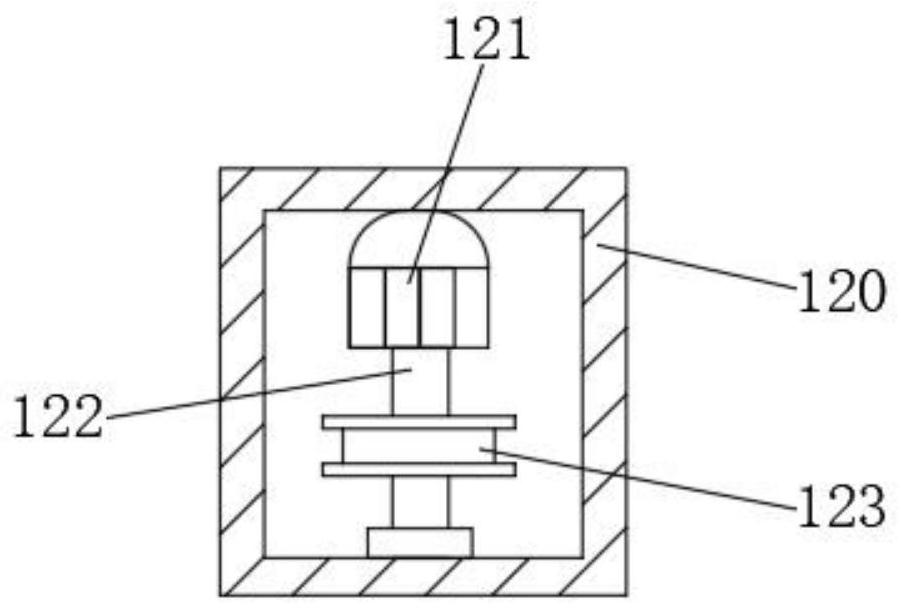

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides an adhesive drying equipment for the shoemaking industry, which includes an equipment main body 1, a housing 2 is fixedly connected to the top of the equipment main body 1, a base 3 is provided under the equipment main body 1, and the equipment main body 1 A weighing device 4 is provided at the inner bottom of the storage box 5 for weighing the quality change during the drying process of the storage box 5. A storage box 5 is provided inside the equipment main body 1 for storing adhesives. The two sides of the storage box 5 The walls are fixedly connected with fixed side panels 6, and the lower surface of the storage box 5 and near the edges of both sides are fixedly connected with vibration blocks 7, which are used to make the storage box 5 vibrate and increase the effect of drying. The walls are fixedly connected with lead rods 11, which play the role of guiding the traction rope 8. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com