Stainless steel self-sealing gel purification column device

A stainless steel column and self-sealing technology, which is applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of economic loss, inability to flow liquid in one direction, and no self-sealing function, etc., to achieve convenient replacement, Avoid the effects of reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

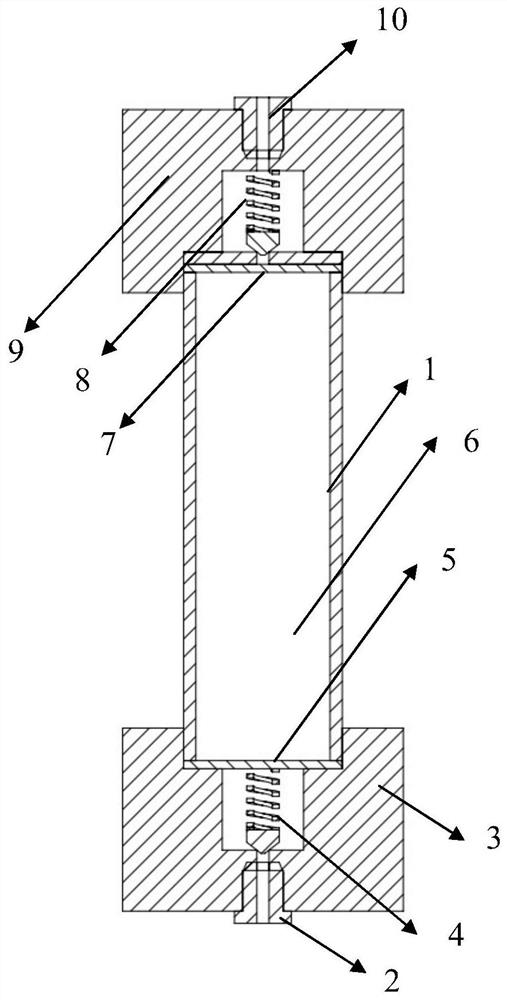

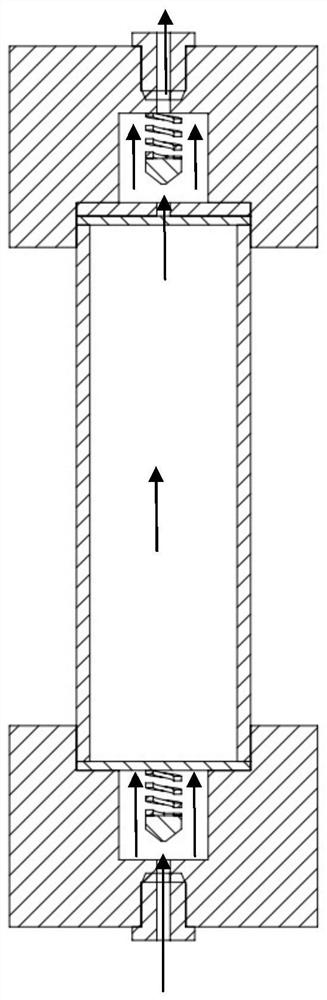

[0023] Such as figure 1 As shown, the present invention provides a stainless steel self-sealing gel purification column device, which has a stainless steel column 1, which can hold gel filler 6 inside, and the liquid inlet end of the stainless steel column tube 1 is provided with a liquid inlet sieve plate 5 And be fixed with the liquid inlet sealing nut 3, the liquid outlet is provided with the liquid outlet sieve plate 7 and fixed with the liquid outlet sealing nut 9, and the characteristics of the present invention are:

[0024] A liquid inlet unidirectional control mechanism 4 is provided between the liquid inlet sieve plate 5 and the liquid inlet sealing nut 3, so that the liquid can flow into the stainless steel column tube 1 from the liquid inlet end of the stainless steel column tube 1 without being unable to reverse outflow;

[0025] A liquid outlet one-way control mechanism 8 is provided between the liquid outlet sieve plate 7 and the liquid outlet sealing nut 9, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com