Hole-making process method adopting pre-positioning and secondary precise positioning combination

A technology of precise positioning and process method, which is applied in the direction of manufacturing tools, drilling molds for workpieces, metal processing equipment, etc., can solve the problems of unstable accuracy, affecting the accuracy of hole making, and low production efficiency, so as to avoid errors, Improvement of productivity and shortening of drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

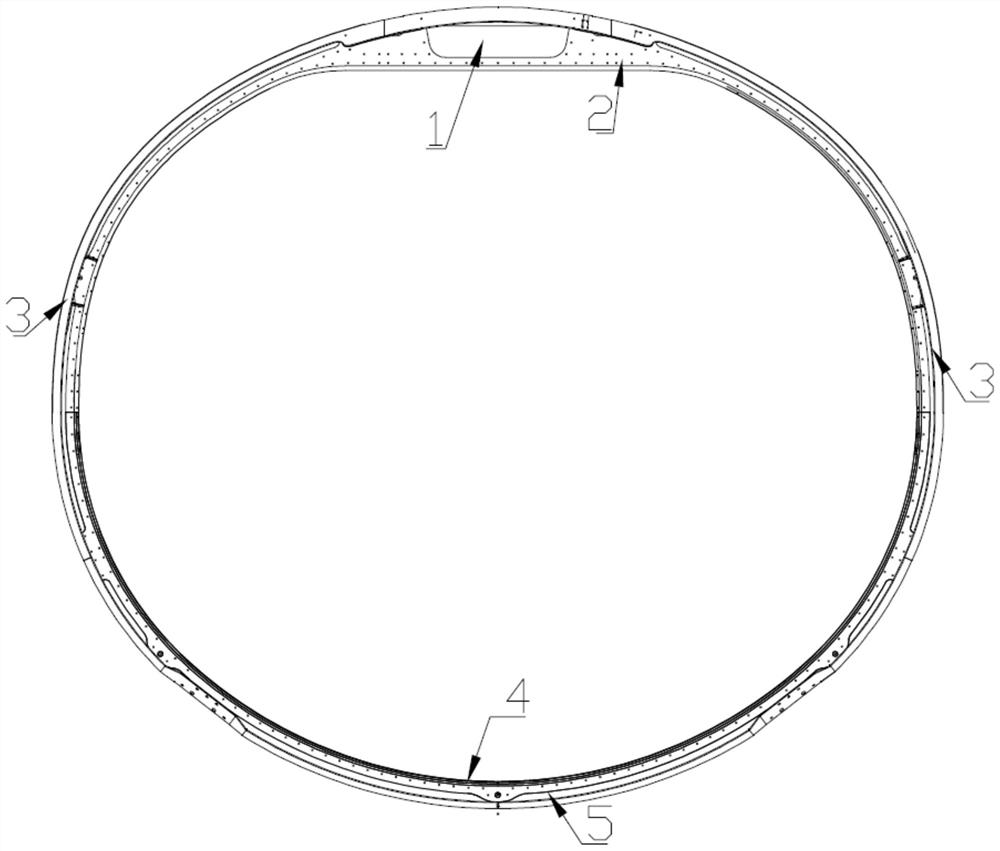

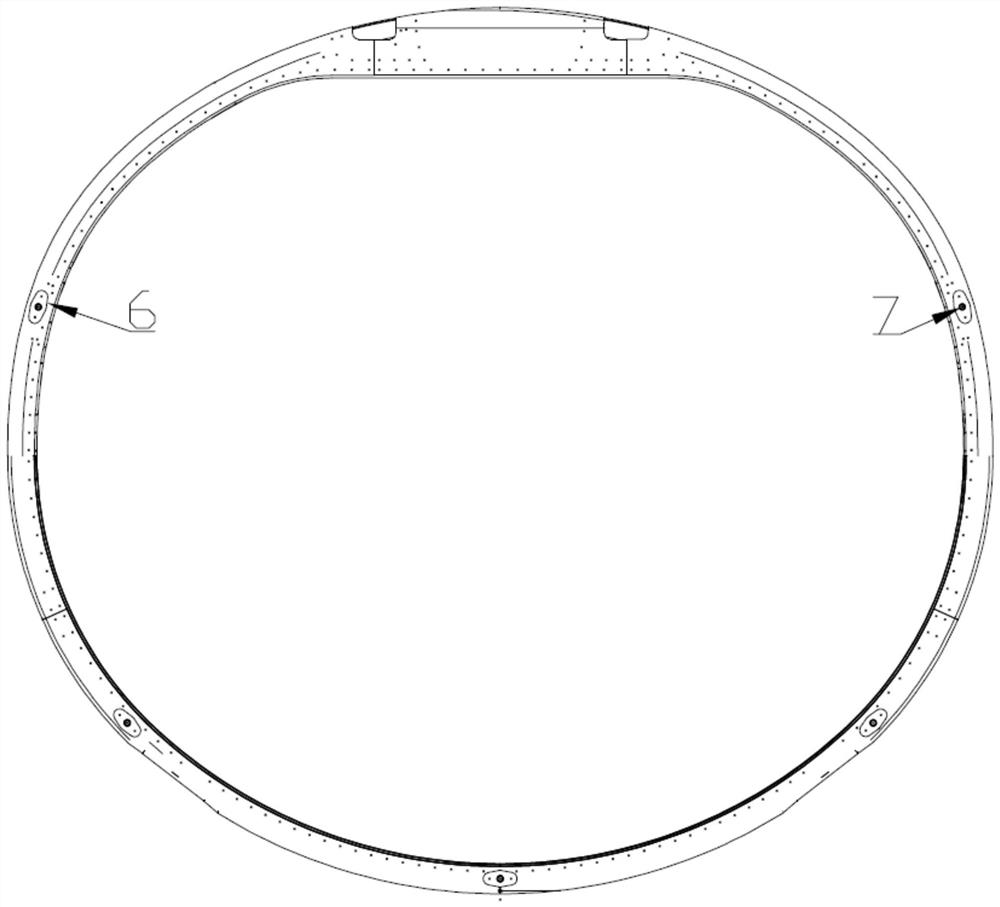

[0027] The method of the present invention is a hole-making process combining pre-positioning and secondary precise positioning. The reinforcing ring includes an upper frame edge, a lower frame edge, two side frame edges, an upper reinforcing frame, a lower reinforcing frame and a composite material shell, comprising the following steps:

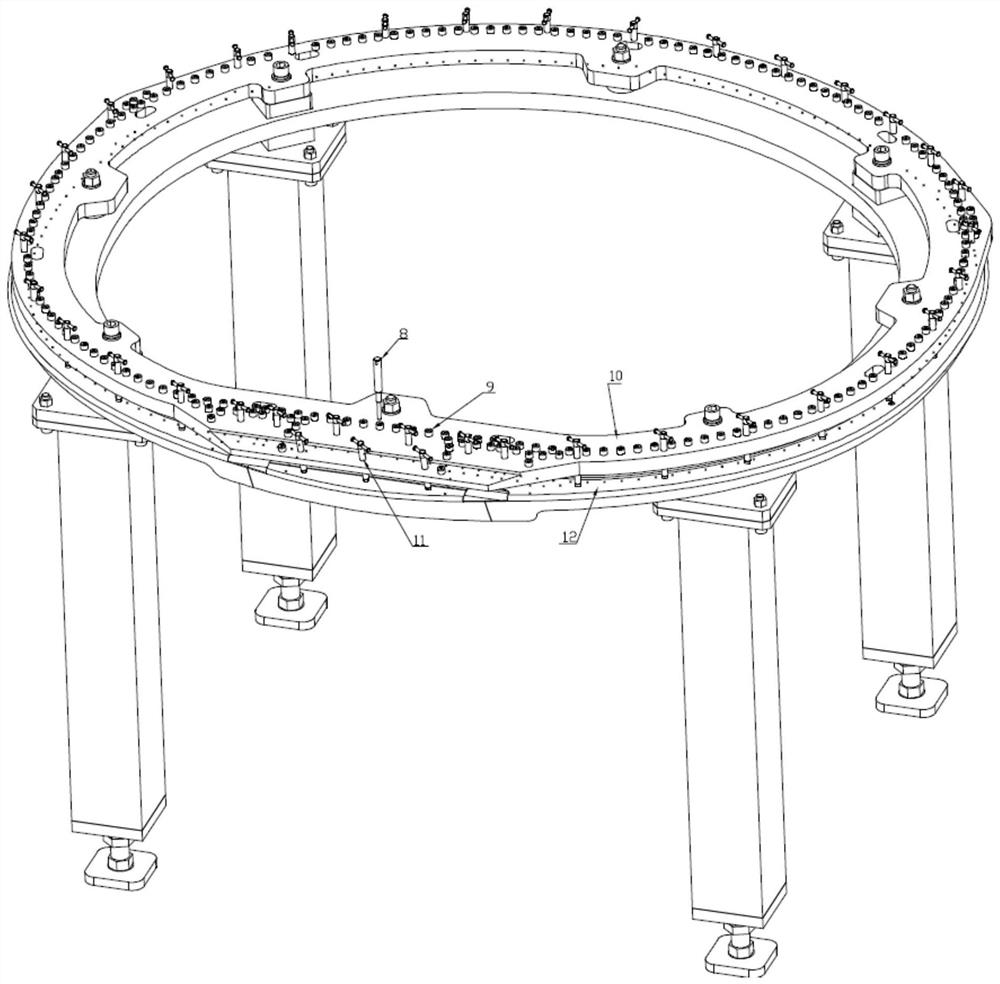

[0028] Step 1. Install the upper frame edge, the lower frame edge, the two side frame edges, the upper reinforcement frame, the lower reinforcement frame and the composite material shell on the installation and inspection fixture for pre-positioning, and splice the reinforcement ring;

[0029] Step 2: Make several evenly distributed positioning holes on the reinforcement ring by using the jig template for installation and inspection;

[0030] Step 3. Disassemble the reinforcing ring, and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com