Device for pressing magnetic component into cup cover

A technology of magnetic components and cup lids, which is applied in the field of press-fitting devices, can solve the problems of low work efficiency, high labor intensity, and easy accidental injury to hands, and achieve the effect of simple structure, reduced labor intensity, and reduced risk of accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

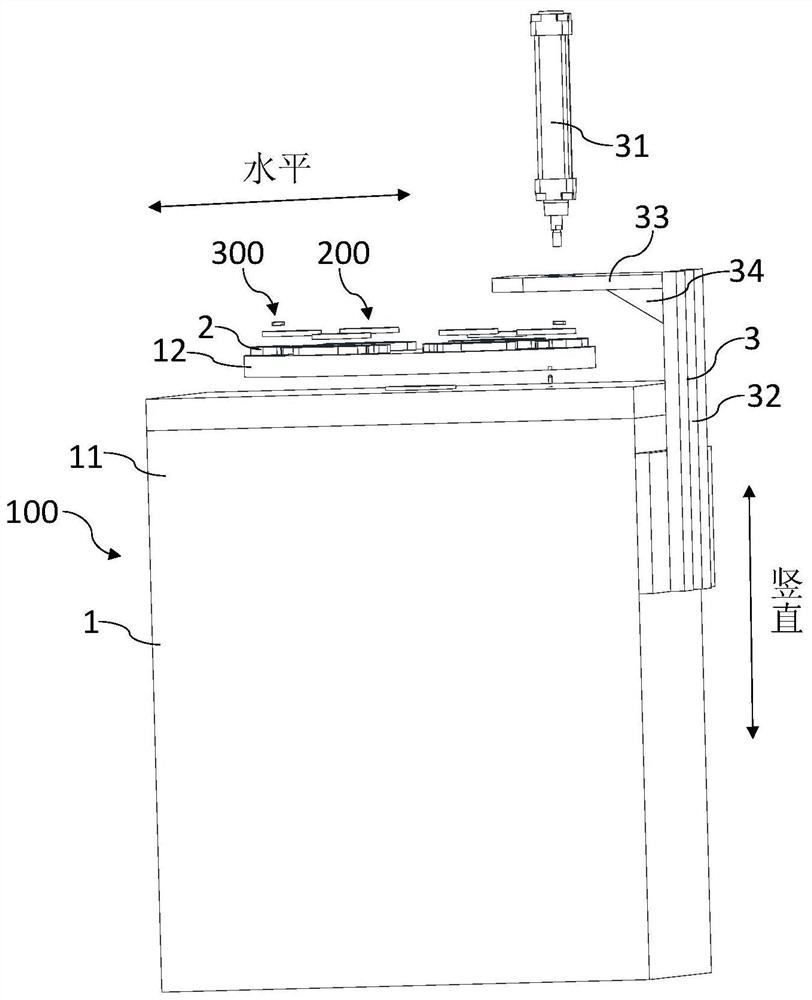

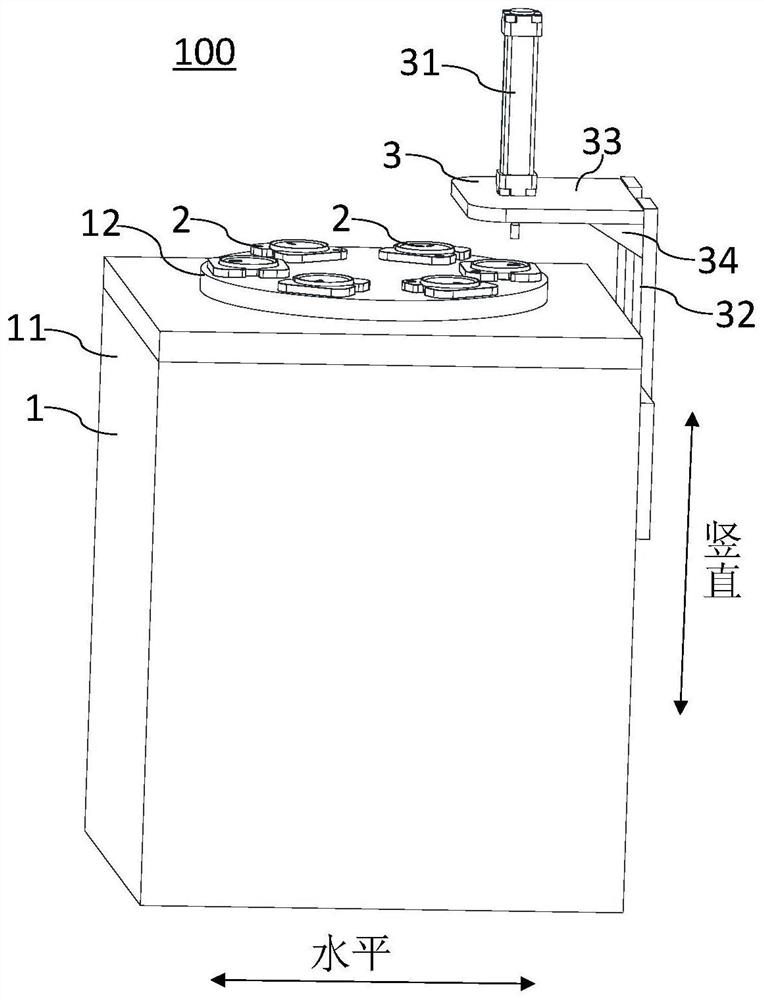

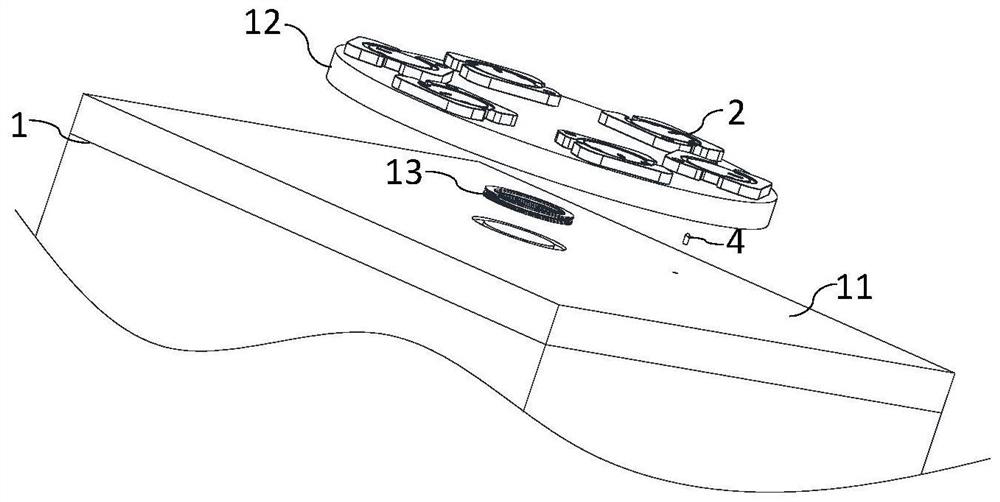

[0022] figure 1 It is an exploded view of the device for pressing the magnetic member into the cup cover according to the embodiment of the present invention; figure 2 It is a perspective view of a device for pressing a magnetic member into a cup cover according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown, the device 100 is used to press the magnetic member 300 into the cup lid 200 . The cup cover 200 is provided with an assembly groove for accommodating the magnetic member 300 , and the assembly groove is adjacent to the charging port of the cup cover 200 . The device 100 includes a base 1 , a constraining member 2 and a pressing mechanism 3 . Among them, the constraining member 2 is arranged on the machine base 1, which can accommodate or clamp the cup cover 200 and position it, so that the pressing mechanism 3 arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com