DH-series manual grain drawing and blunt knife all-in-one machine with angle convenient to adjust

An angle-adjusting, all-in-one machine technology, which is applied in the field of wood floor processing, can solve the problems of cumbersome cutting process, inconvenient collection and treatment of wooden floors, inability to export wooden floors, and inconvenient collection and treatment of waste materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

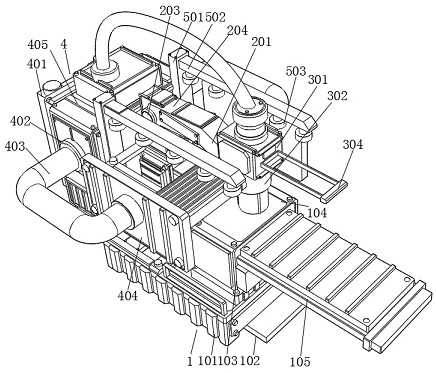

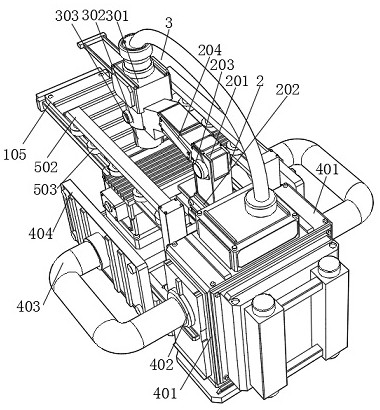

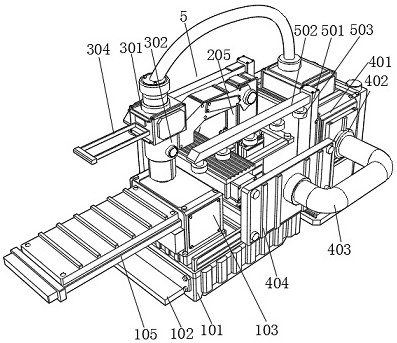

[0028] see Figure 1-5 , the present invention provides the following technical solutions: a DH series hand-drawn blunt knife all-in-one machine that is convenient to adjust the angle, including a support mechanism 1, and a mechanical support mechanism 2 is installed on the side of the support mechanism 1 through a support bracket 101. One end of the support mechanism 2 is fixedly installed with a blunt knife cutting mechanism 3 through the hinged cantilever 204 provided, and one end of the blunt knife cutting mechanism 3 is fixedly installed with a dust suction mechanism 4, and the side wall surface of the dust suction mechanism 4 is fixedly installed with Atomization mechanism5.

[0029] In this embodiment: the support bracket 101 is fixedly installed at the four corners of the bottom of the support mechanism 1, the bottom surface of the support bracket 101 is fixedly equipped with a dust collection box 102, and the top of the dust collection box 102 is provided with an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com