Assembly type door plate structure convenient to assemble

A prefabricated, door-panel technology, applied in door leaves, windows/doors, fire-resistant doors, etc., can solve the problems of composite door panels with strong functions, strong structure, troublesome assembly, etc., to achieve enhanced decoration and functionality, simple installation, and enhanced strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

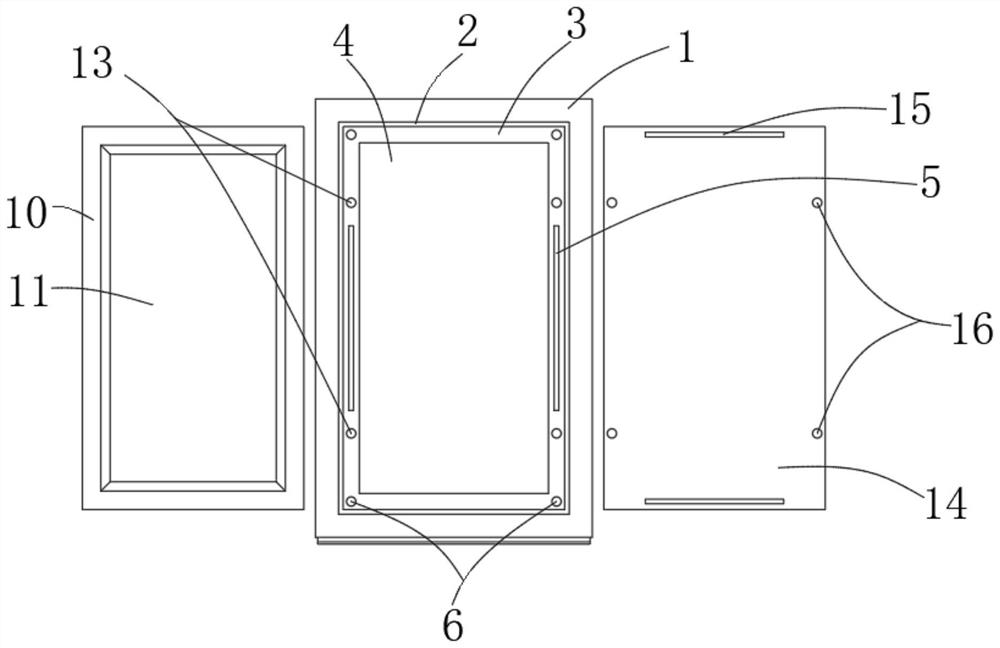

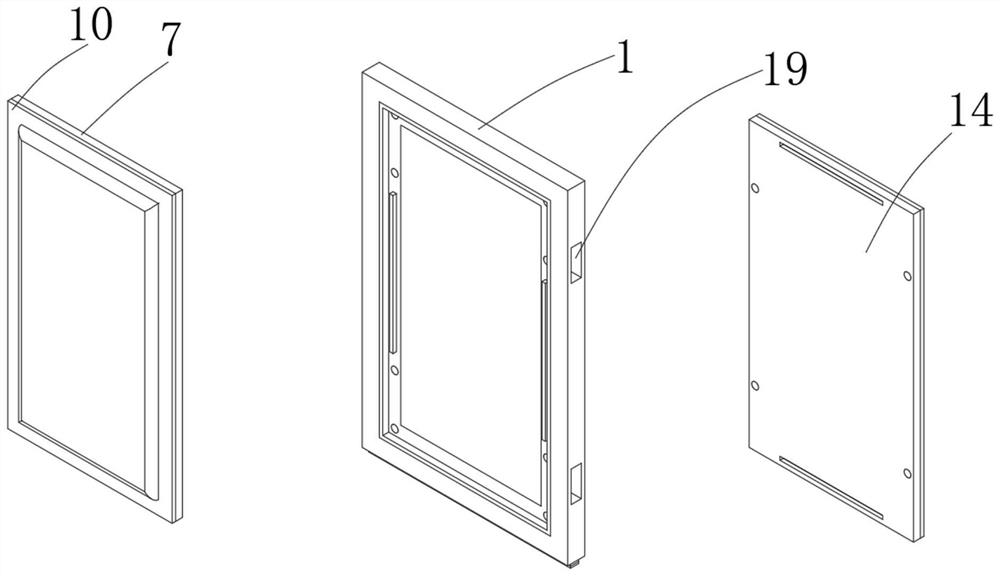

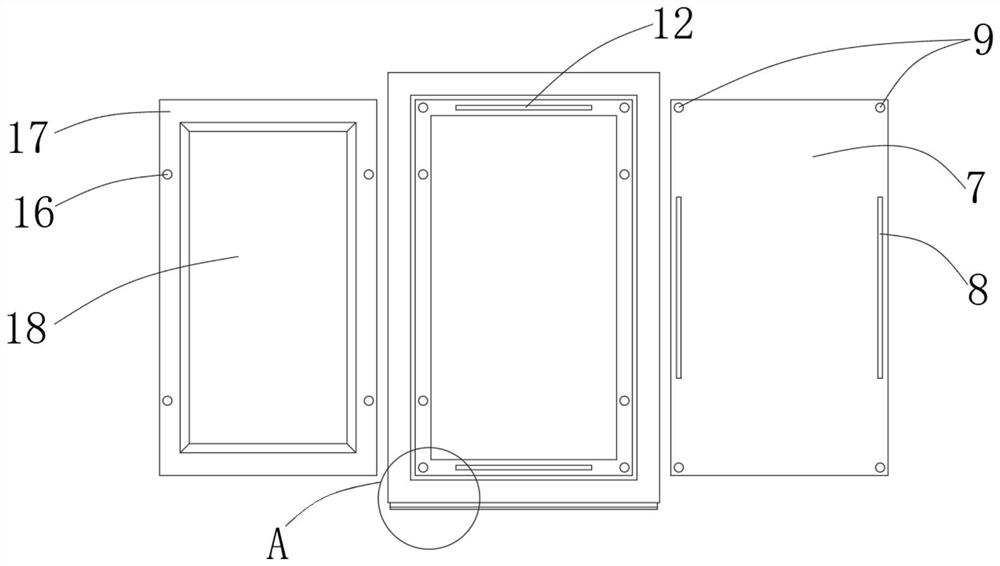

[0038] Example: such as Figure 1-5This embodiment shown is a method of using an assembled door panel structure that is easy to assemble: first install the front clamping plate 7, snap the vertical bar 5 into the vertical groove 8, and fix the front plate fixing hole 6 with the front plate to adapt to the Holes 9 make the front clamping plate 7 more stable; after installing the rear clamping plate 14, the cross bar 12 is inserted into the transverse groove 15, and then the rear plate fixing hole 16 and the rear plate adaptation hole 13 are fixed with bolts to make the rear plate The clamping plate 14 is installed more stably; the door shaft is installed in the door shaft groove 19, and the door lock is installed in the door lock groove 20; then the door body is installed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap