A building-type absorption heat exchange station that can realize district heating

An absorption and heat exchange station technology, applied in the field of energy saving, can solve the problems of small footprint, difficult implementation, and extension of pipelines, so as to reduce the number of equipment, reduce initial investment, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

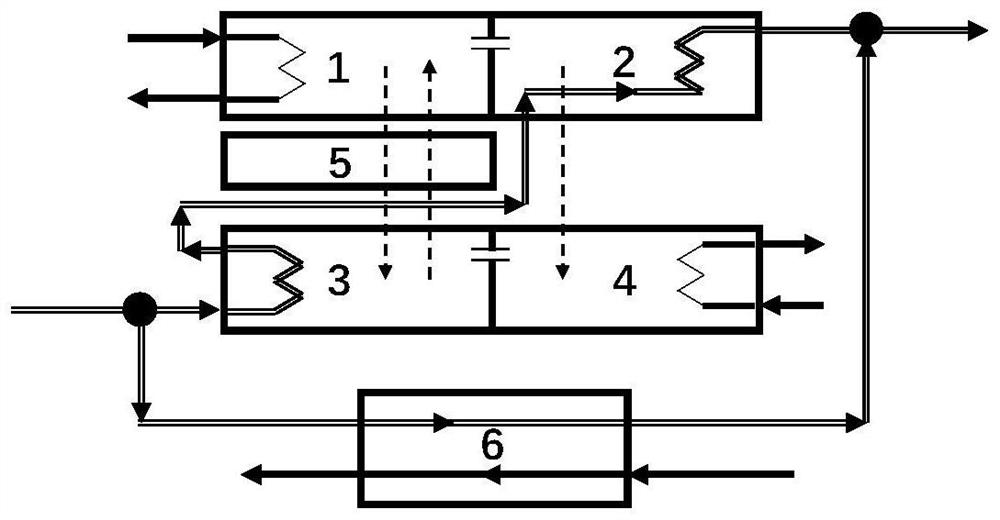

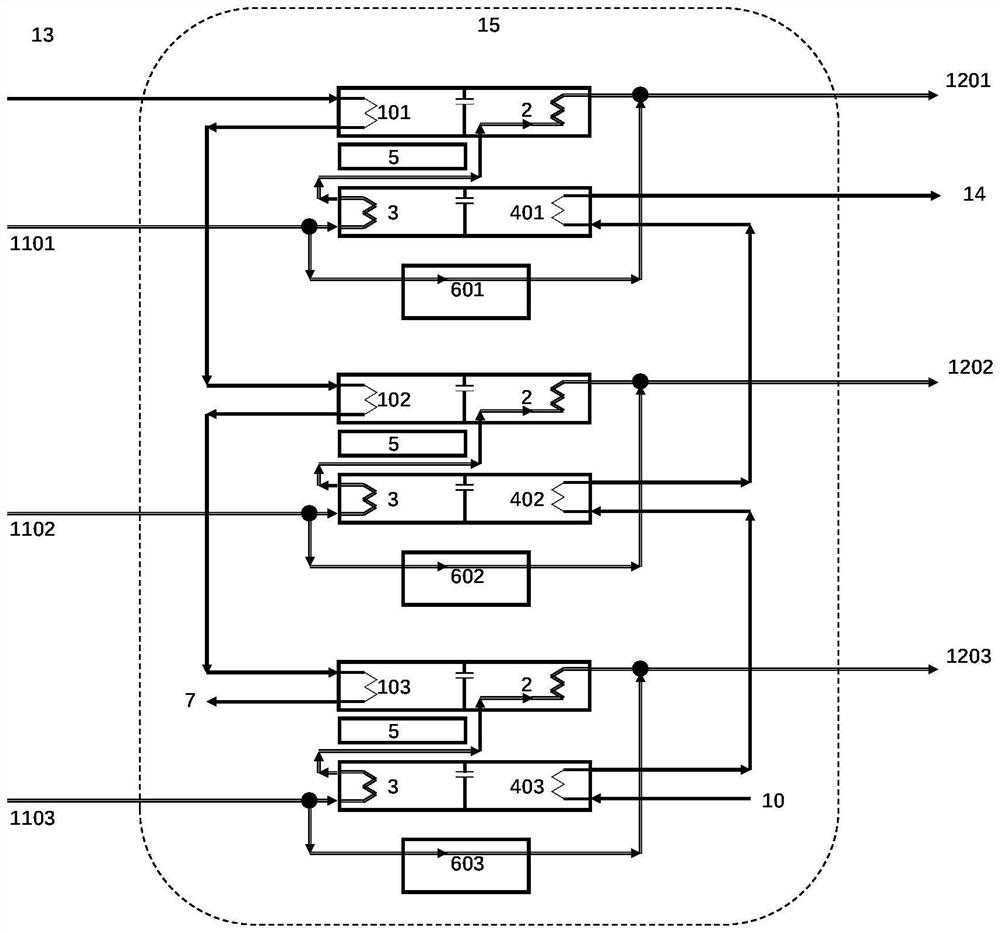

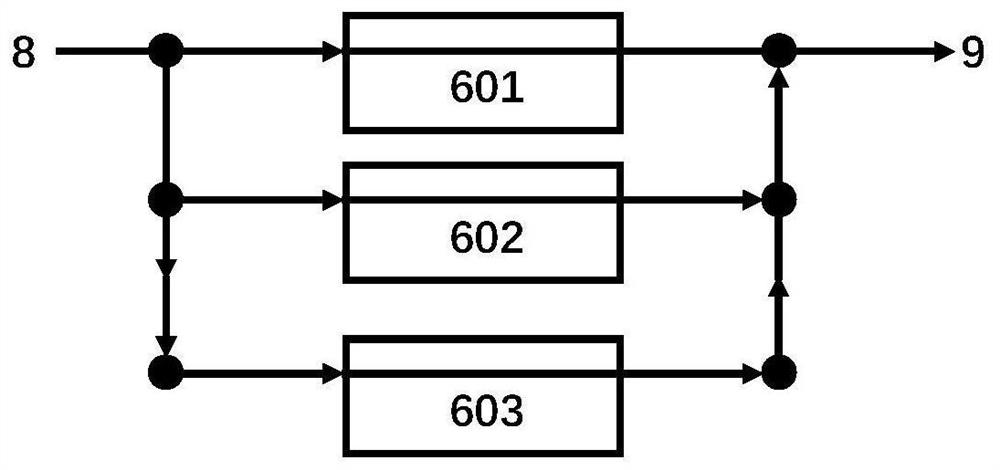

[0045] Such as Figure 1 to Figure 5 The shown embodiment 1 of a building-type absorption heat exchange station of the present invention that can realize heating in three districts provides heat for the low, middle and high districts of the building respectively according to the most common usage conditions, including: three Absorption heat exchanger 15 for separate heat supply in different areas, water supply and constant pressure device for different areas 16, primary network booster pump 20, 3-stage independent secondary network circulation pump 21, flow meter 22, thermometer 23, pressure gauge 24, primary network pipe The primary network inlet 13 is connected with the generator hot water pipeline inlet of the building-type absorption heat exchanger 15 through a thermometer 23 and a pressure gauge 24, so as to enter the first-stage generator 1; The outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com