Temperature data input method for hot gas defrosting group control

A technology of temperature data and input method, which is applied in household refrigeration equipment, defrosting, application, etc., can solve the problems of high cost, high equipment composition cost, affecting project duration and cost, etc., and achieve the effect of reducing cost and facilitating model selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

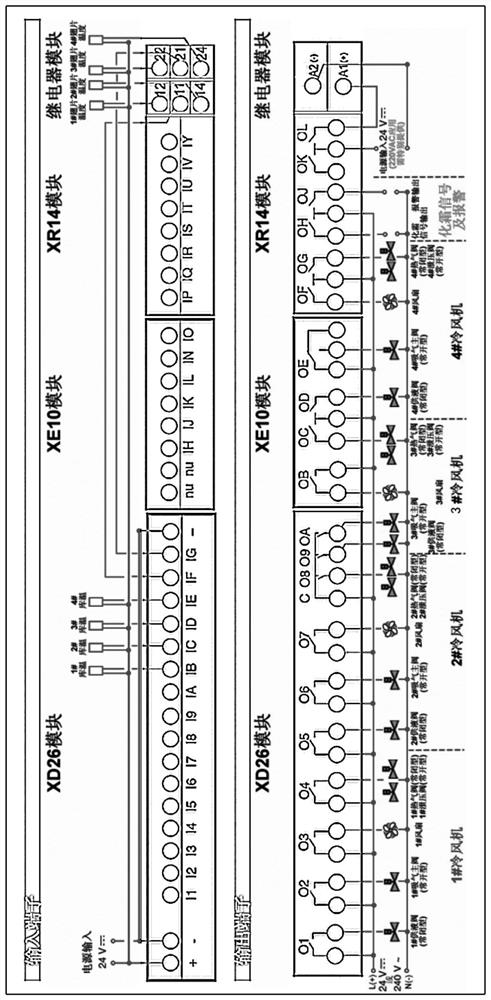

[0014] A temperature data input method for hot gas defrosting group control: it includes an equipment platform and four evaporators, six temperature input points are reserved on the equipment platform, and the fin area of each evaporator is provided with fins Temperature sensor, a total of four fin temperature sensors, connect the four temperature input points on the device to the corresponding temperature sensors of the cold storage corresponding to the four evaporators, so that the equipment platform can monitor the corresponding storage temperature in real time, and then the remaining The two temperature input points are respectively connected to the independent first selection switch and the second selection switch, the input terminals of the first selection switch are respectively connected to the two fin temperature sensors, and the input terminals of the second selection switch are respectively connected to the other two fin temperature sensors. For the chip temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com