Manufacturing method of liquid crystal display panel and liquid crystal display panel

A technology of a liquid crystal display panel and a manufacturing method, which are applied in the directions of separation method, chemical instrument and method, optics, etc., to achieve the effect of improving image sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Apparently, the described embodiments are only some of the embodiments of this application, not all of them. Based on the embodiments in this application, all other embodiments obtained by those skilled in the art without making creative efforts belong to the scope of protection of this application.

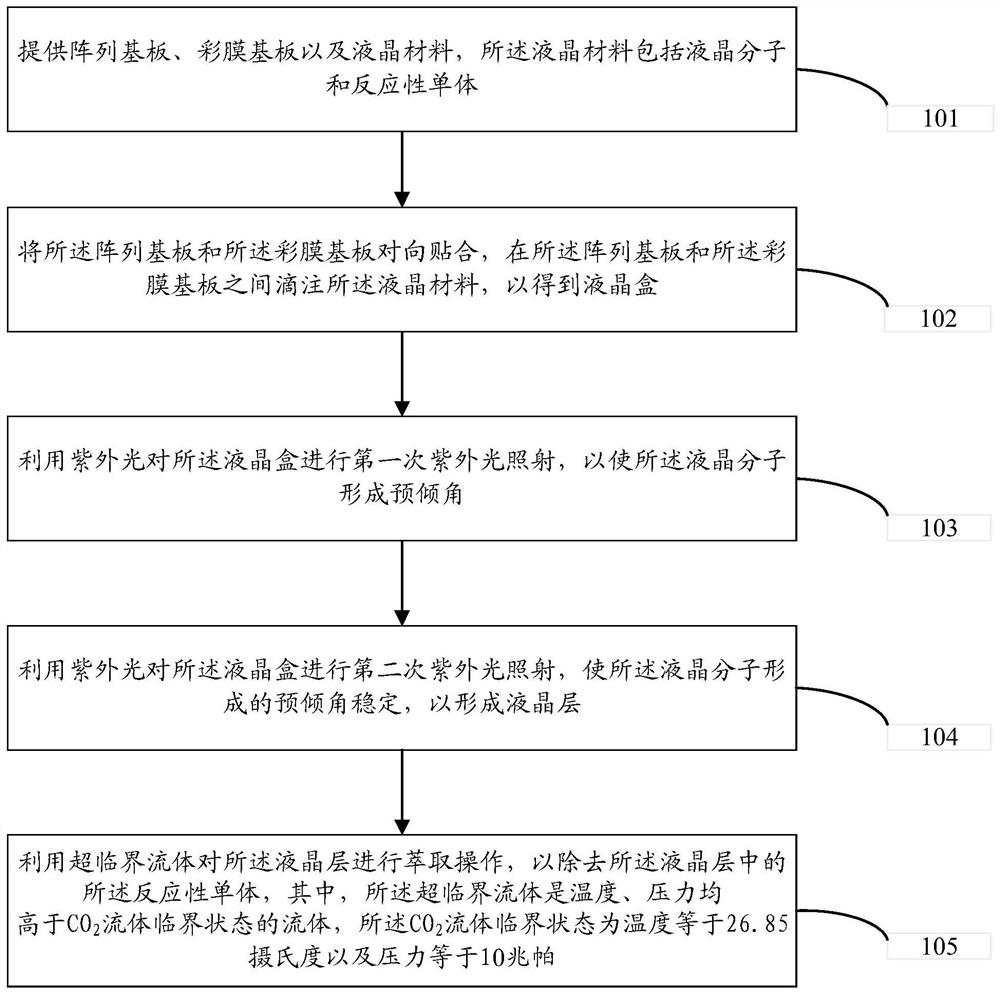

[0042] see figure 1 , figure 1 It is a schematic flow chart of the manufacturing method of the liquid crystal display panel provided by the embodiment of the present application. Such as figure 1 As shown, the manufacturing method of the liquid crystal display panel provided in the embodiment of the present application includes the following steps:

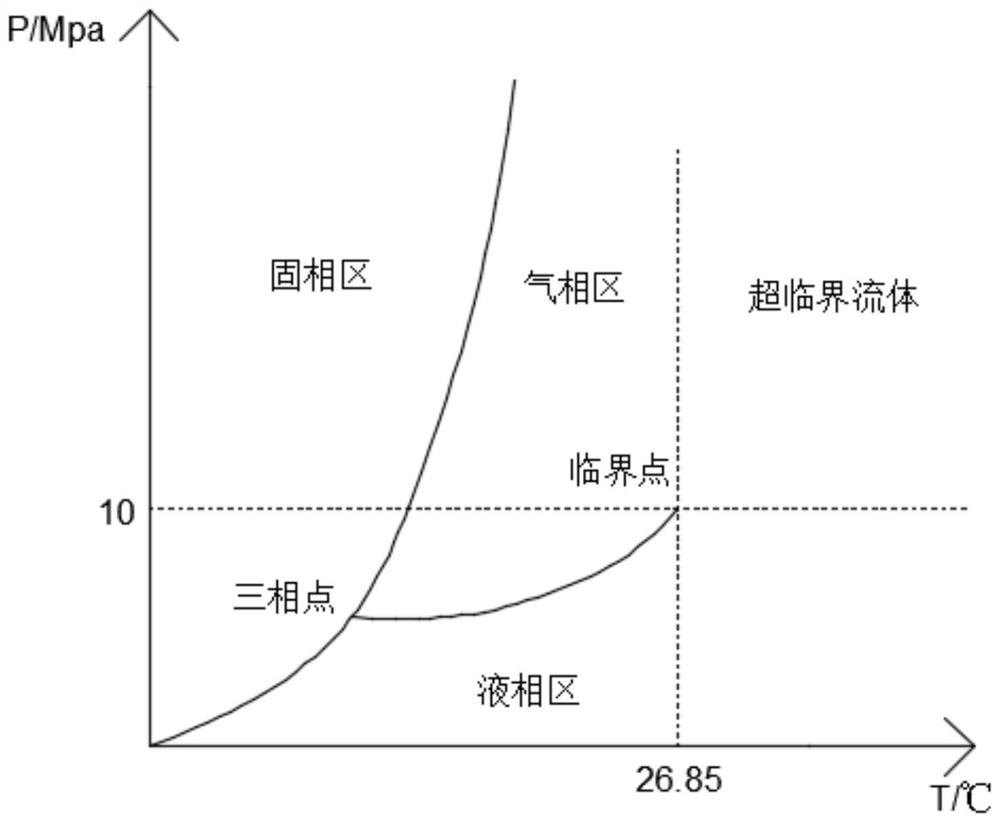

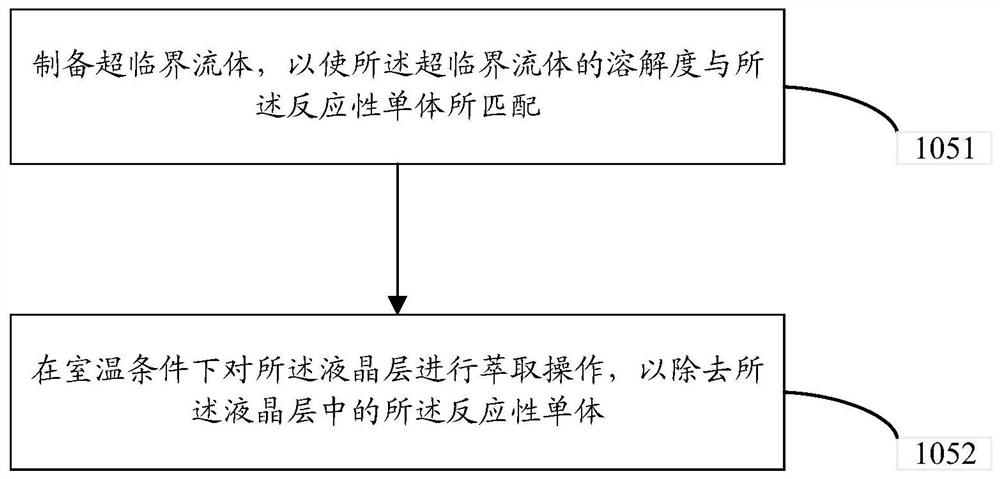

[0043] 101. Provide an array substrate, a color filter substrate, and a liquid crystal material, where the liquid crystal mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap