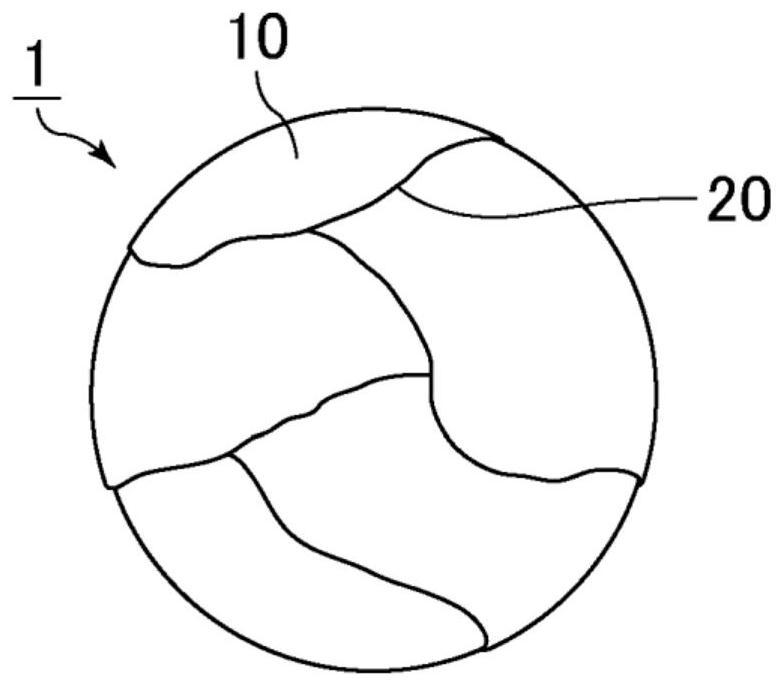

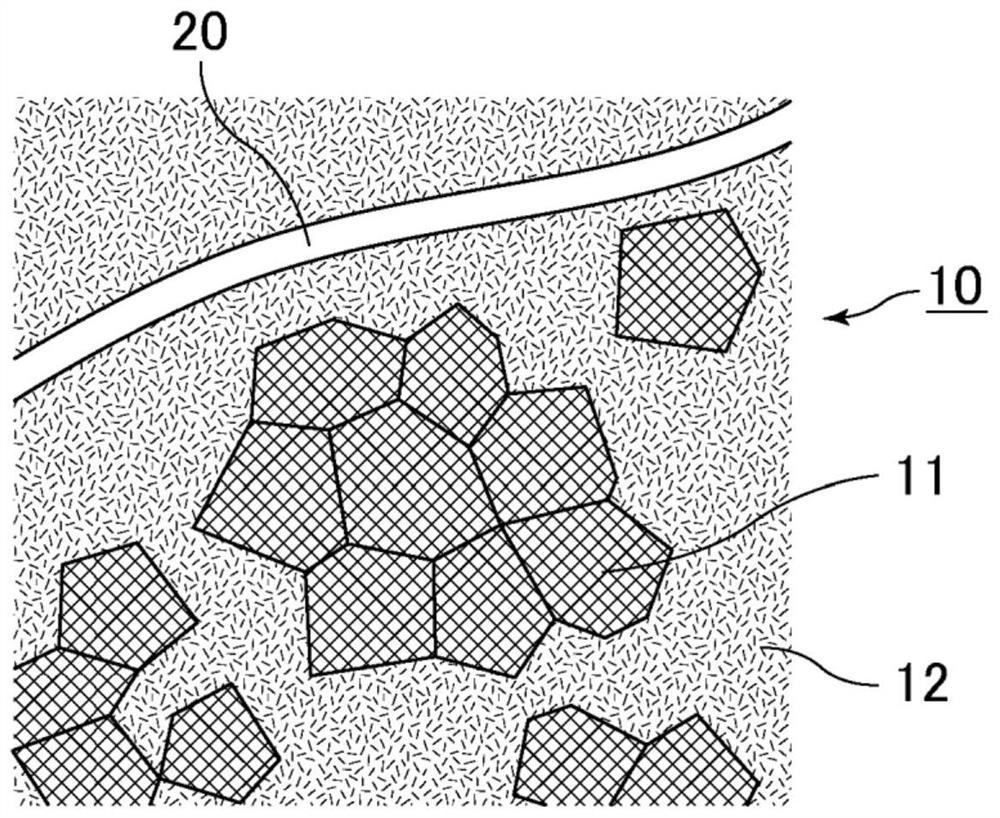

Iron alloy particles and method for producing iron alloy particles

A manufacturing method and ferroalloy technology, applied in transportation and packaging, metal processing equipment, magnetic materials, etc., can solve the problem of increased loss of magnetic components and achieve good high-frequency characteristics and high saturation magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

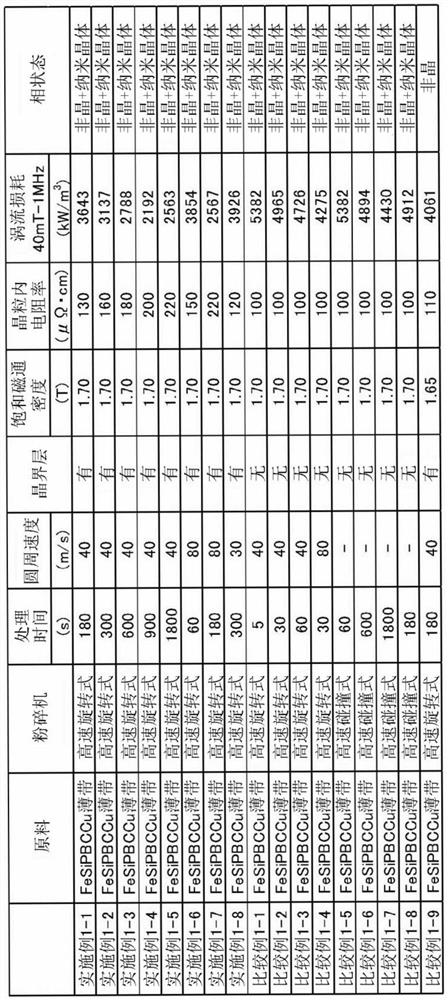

[0067] An alloy ribbon having a composition of FeSiPBCCu produced by a single-roll quenching method was prepared as a raw material. The composition used in the embodiment is Fe 84.8 Si 0.5 B 9.4 P 3.5 Cu 0.8 C 1 . This alloy ribbon was pulverized using a high-speed rotary pulverizer.

[0068] As a high-speed rotary pulverizer, a HYBRIDIZATION SYSTEM (manufactured by Nara Machinery Manufacturing Co., Ltd., NHS-0 type) was used. Table 1 shows the processing time (rotation time of the rotor) and peripheral speed (rotation speed of the rotor).

[0069] After pulverization, heat treatment was performed at 500° C. for 1 hour. Through the above operations, alloy particles are produced.

Embodiment 1-2~ Embodiment 1-8

[0071] Alloy particles were produced by performing the same treatment as in Example 1-1 except that the treatment time and peripheral speed were changed to the values shown in Table 1.

Embodiment 2-1

[0098] An alloy ribbon having a composition of FeSiPBCCu produced by the single-roll quenching method was prepared as a raw material in the same manner as in Example 1-1. After the alloy ribbon was heat-treated under the conditions shown in Table 2, alloy particles were produced by performing the same treatment as in Example 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com