Magnesium-aluminum double-metal hydroxide loaded ferrous sulfide composite material as well as preparation method and application thereof

A hydroxide, composite material technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as poor removal of low-concentration mercury, achieve inhibition of precipitation, wide application prospects, and achieve solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

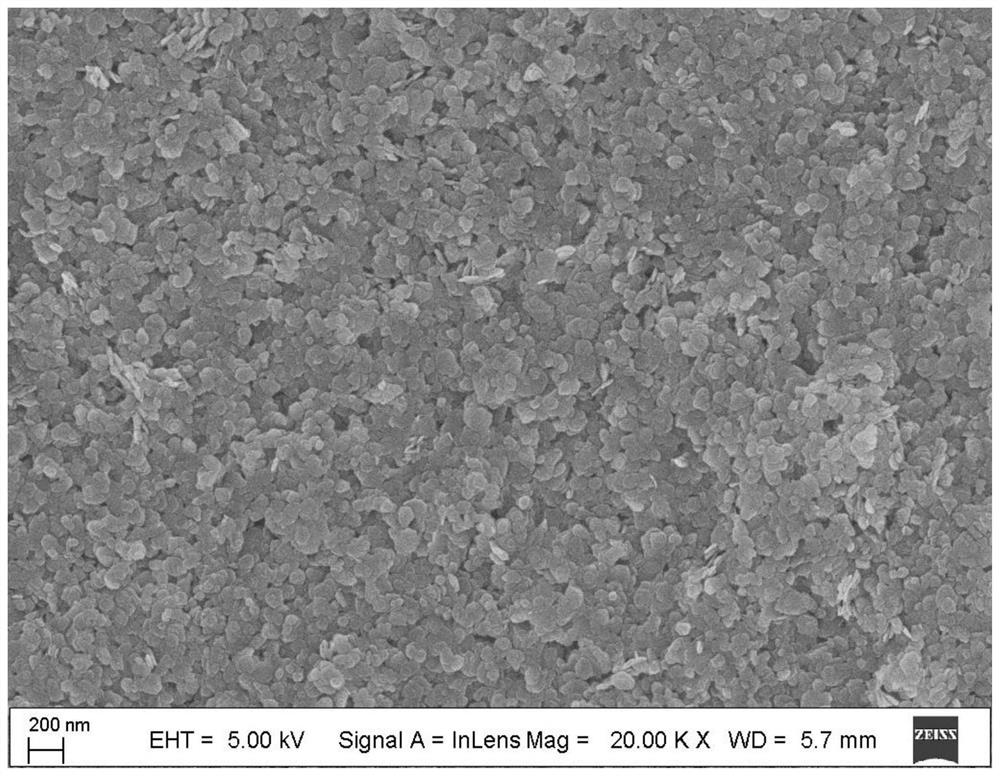

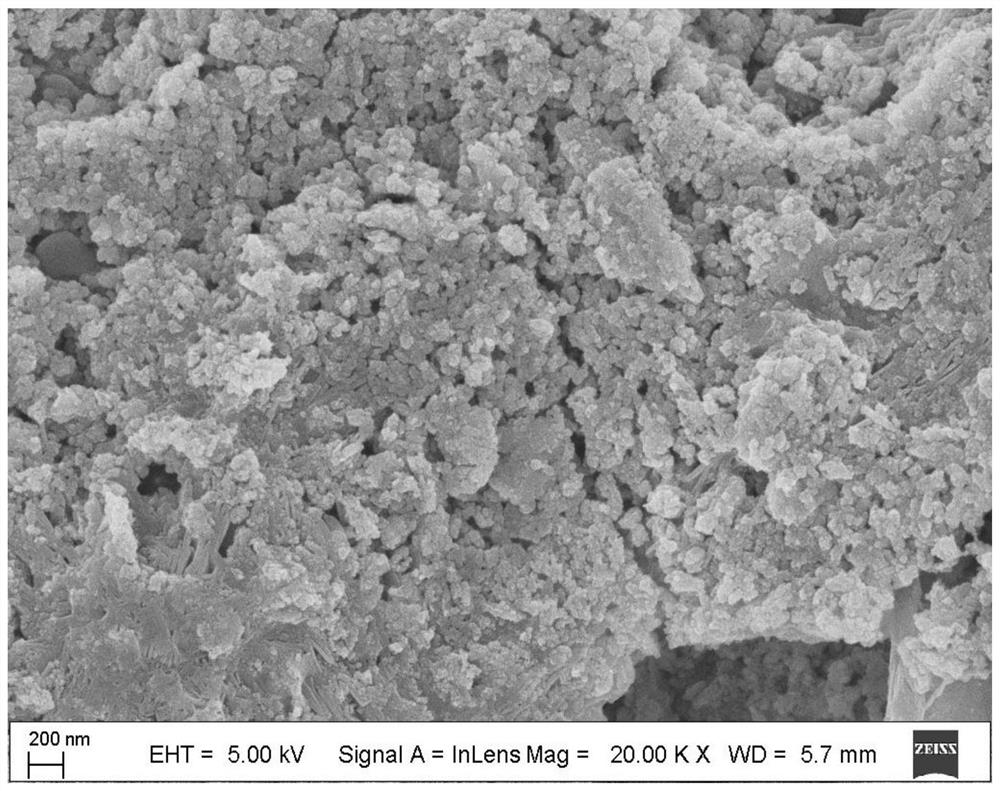

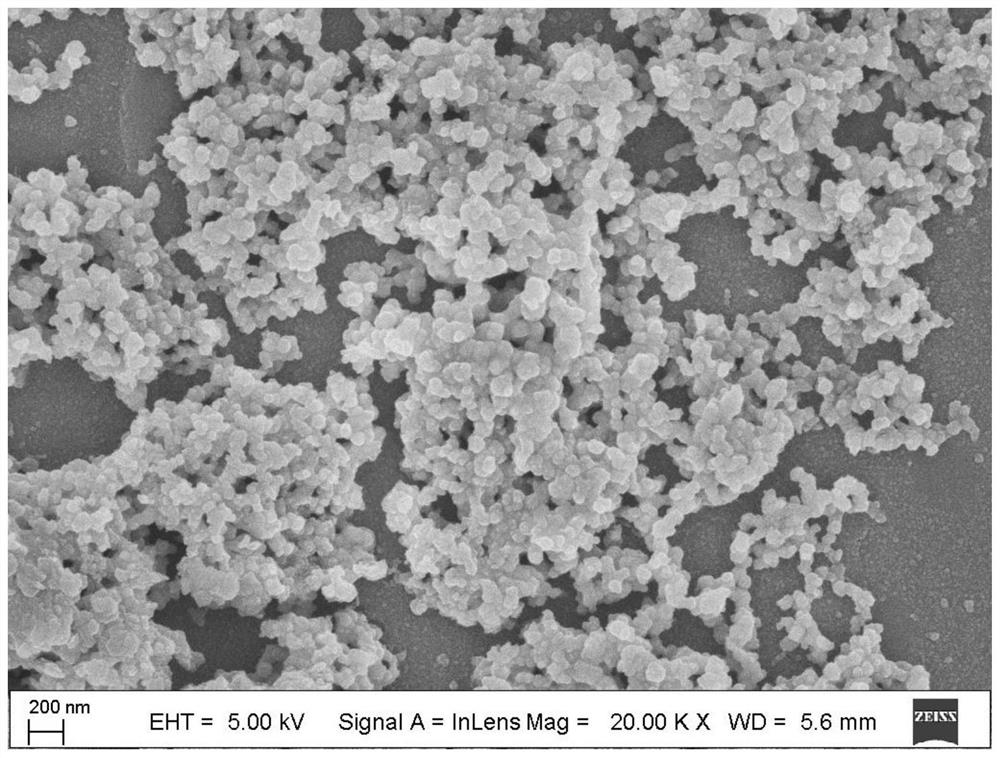

[0046] Example 1: FeS@Mg 2 Preparation of Al-LDH composites

[0047] (1) Magnesium aluminum double metal hydroxide (Mg 2 Al-LDH) material preparation: 12.07g AlCl 3 ·6H 2 O was dissolved in 500mL deionized water under magnetic stirring to obtain solution A, and 20.33g MgCl 2 ·6H 2 O was dissolved in 500mL deionized water under magnetic stirring to obtain solution B. After mixing solution A and solution B, magnetically stirred at room temperature for 30min, and added 80mL of ammonia water to adjust the pH value of the mixed solution to 10 to form a white colloid. After 60 minutes, the white colloid was centrifuged and washed with deionized water, and dried in an oven at 80°C for 24 hours to obtain Mg 2 Al-LDH material is spare.

[0048] (2) FeS@Mg 2 Preparation of Al-LDH composites: under the conditions of magnetic stirring and nitrogen protection, 1.58gFeSO 4 ·7H 2 O was dissolved in 485mL deionized water, and then 0.5g Mg 2 Al-LDH was added therein, and the magnetic...

Embodiment 2

[0050] Example 2FeS@Mg 2 Preparation of Al-LDH composites

[0051] Step (1) preparation method is with embodiment 1, makes Mg 2 Al-LDH material spare;

[0052] With the Mg in the embodiment 1 step (2) 2 Change the quality of Al-LDH to 0.25g, and other conditions are the same, get FeS@Mg 2 Al-LDH composites with FeS and Mg 2 The mass ratio of Al-LDH is 1:05;

[0053] With the Mg in the embodiment 1 step (2) 2 Change the quality of Al-LDH to 1g, and other conditions are the same, get FeS@Mg 2 Al-LDH composites with FeS and Mg 2 The mass ratio of Al-LDH is 1:2;

[0054] With the Mg in the embodiment 1 step (2) 2 Change the quality of Al-LDH to 2g, and other conditions are the same, get FeS@Mg 2 Al-LDH composites with FeS and Mg 2 The mass ratio of Al-LDH is 1:4;

[0055] With the Mg in the embodiment 1 step (2) 2 The quality of Al-LDH is changed to 4.4g, and other conditions are the same, FeS@Mg is obtained 2 Al-LDH composites with FeS and Mg 2 The mass ratio of Al...

Embodiment 3

[0058] Example 3FeS@Mg 2 Mercury removal from surface water by Al-LDH composites under anaerobic conditions

[0059] The FeS of comparative example 1, the Mg of embodiment 1 were respectively 2 Al-LDH and FeS@Mg with different mass ratios 2 Al-LDH composite material (prepared in Example 1 and 2) is used to remove surface water under anaerobic conditions, wherein FeS, Mg 2 Al-LDH and FeS@Mg 2 The concentration of Al-LDH composite material in the surface water to be treated is 20mg / L, the concentration of mercury in the surface water to be treated is 100μg / L, the pH value of the surface water to be treated is 7.0, and the removal time is 72 hours. The removal effect is shown in Figure 5 .

[0060] Figure 5 In order to compare different FeS and Mg 2 Mass ratio of Al-LDH to FeS@Mg 2 Effect of Al-LDH composites on mercury removal in surface water. With Mg 2 As the mass ratio of Al-LDH increases, the removal of mercury by the composite material shows a trend of first incr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap